Many entrepreneurs have been struggling to determine if laser cutting is cost-effective. As we delve into this topic, we’ll explore the impact of laser technology on traditional methods and highlight some success stories.

We will also analyze how CNC-controlled machines offer high accuracy and reduced lead times, making the laser cutting process more efficient. A key aspect of our discussion will focus on power consumption in comparison to other techniques such as plasma or waterjet cutting.

The reduction of waste material through laser cutters is another vital point that contributes to its cost-effectiveness. We’ll look at how minimizing waste generation can have long-term financial benefits for your business.

In addition, we’ll discuss the versatility and adaptability across various applications which makes it an ideal solution for complex jobs without incurring additional expenses. Lastly, we’ll examine factors affecting efficiency and overall costs when considering if owning your own cutter versus outsourcing is best for you.

Join us as we answer the question:

Table of Contents:

- The Revolution of Laser Cutting in Manufacturing

- Cost-effectiveness and Efficiency with Laser Cutting

- Reducing Waste Material with Laser Cutting

- Versatility and Adaptability: Laser Cutting Machines

- Factors Affecting Efficiency and Overall Costs

- Outsourcing Vs Owning Your Own Cutter

- AP Precision Metals: Shining Bright in San Diego

- FAQs in Relation to Is Laser Cutting Cost Effective

- Conclusion

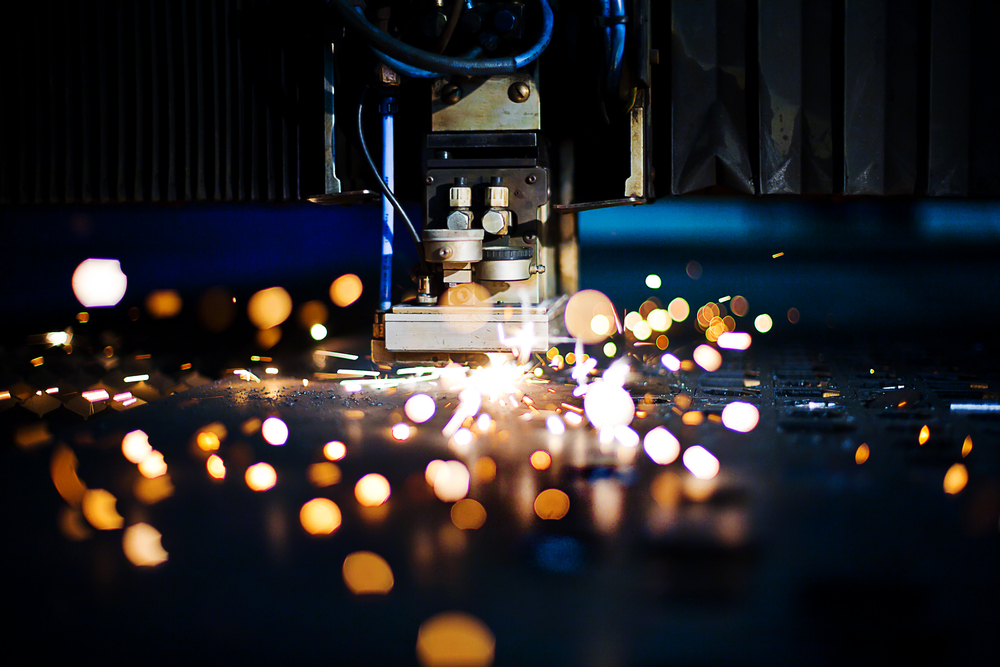

The Revolution of Laser Cutting in Manufacturing

Laser cutting technology has been a game-changer for the manufacturing industry. With over 35 years of experience, companies like Glenn Metalcraft have capitalized on this advanced technique known for its precision and speed in cutting metal.

The impact of laser cutting on traditional manufacturing methods

Laser cutters: where accuracy meets efficiency. Say goodbye to deformation and hello to intricate designs. It’s like magic, but with lasers.

Case study: Glenn Metalcraft’s successful adoption of laser cutting

Glenn Metalcraft’s success story is a shining example of how laser cutting can transform business operations. They’ve slashed production time, maintained exceptional quality, and saved money. Talk about a triple threat.

This revolutionary approach not only enhances output, but also enables producers to offer superior goods at prices that are competitive. Precision cuts at lightning speed? That’s how you stay ahead in the cutthroat marketplace.

Cost-effectiveness and Efficiency with Laser Cutting

Laser cutters: saving time, reducing costs, and making your business shine.

CNC-controlled Machines: Precision at its Finest

CNC-controlled machines: accurate, fast, and error-free. Say goodbye to production mishaps.

Lower Power Consumption, Higher Savings

Laser cutters: the energy-efficient choice. Forget high utility bills, embrace cost-efficiency.

Reducing Waste Material with Laser Cutting

Laser cutting technology is a cut above the rest when it comes to waste reduction. Unlike traditional manufacturing methods that leave behind heaps of scrap, laser cutters are precision masters that minimize material wastage.

How laser cutters work their magic

Laser cutters slice through materials with surgical precision, leaving behind clean cuts and minimal scrap. By reducing scrap, laser cutters save on materials and minimize the need for waste disposal or recycling.

Saving money in the long run

By optimizing resource usage and cutting down on disposal costs, not only is reducing waste good for the environment but it can also be beneficial to one’s wallet. By optimizing resource usage and cutting down on disposal costs, businesses like AP Precision Metals (AP Precision Services) have seen significant long-term savings.

In an industry where every penny counts, laser cutting is a smart move that combines cost-effectiveness with environmental responsibility.

Versatility and Adaptability: Laser Cutting Machines

The versatility of laser cutting machines saves businesses from expensive customization dies. No extra costs, no extra worries.

Complex Jobs Made Easy

Complex Jobs Made Easy

Laser cutters handle intricate cuts and designs without costly tooling or manual labor. Precision cuts mean less post-processing. Time and resources saved.

Adaptable to Any Material

Laser cutters work on metal, wood, plastic, glass, and more. No need for multiple specialized tools. Expand your product offerings effortlessly.

And if you want even more efficiency, check out fiber lasers. They’re fast, adaptable, and increase productivity. Get the job done in no time.

Factors Affecting Efficiency and Overall Costs

Investing in a high-quality laser cutter may seem pricey, but let’s consider the factors that impact its efficiency. The type of lasers used, warm-up times, and other considerations can all affect the cost-effectiveness of your laser cutting operations.

The type of lasers used can make a big difference in both the quality of cuts and operational costs. CO2 lasers are more affordable but take longer to warm up, while fiber or crystal lasers offer faster speeds at a higher upfront cost.

Warm-up times also play a role in productivity. Longer warm-ups mean delays and more overtime expenses. But fear not, modern ‘instant-on’ laser technology is here to save the day.

Compared to other methods like water jetting or plasma cutting, laser cutters are more economical. They deliver top-notch cuts quickly, reducing project turnaround time. Time is money, folks.

Outsourcing Vs Owning Your Own Cutter

to outsource or to own your own laser cutter. It’s like picking between a wild night out and settling down for the long haul. Both have their perks, but let’s dive into the benefits of owning your own laser cutter.

In-house Cutting: Cut Above the Rest

With your own laser cutter, you’re the boss. No more relying on external factors like shipping delays or quality issues from outsourcing companies. You can ensure top-quality cuts every time, without breaking a sweat.

Reduced Costs Over Time: Money Talks

Yes, owning a laser cutter may require a hefty upfront investment. But think about the long-term savings. Say goodbye to those pesky operational costs and hello to increased efficiency. Cha-ching.

Now, don’t get us wrong. Outsourcing has its perks too. Although outsourcing may be appealing, investing in a cutting-edge technology such as laser cutting could revolutionize your business despite the cost.

AP Precision Metals: Shining Bright in San Diego

In the cutthroat world of metal fabrication and manufacturing, AP Precision Metals stands tall, laser-focused on success.

With their advanced laser cutting capabilities, AP Precision Metals have outdone the competition and shown that having the right technology is more important than size.

By investing in top-notch laser cutters, they’ve not only slashed operational costs but also boosted productivity and efficiency. Talk about cutting-edge strategies.

But it’s not just about the bottom line. AP Precision Metals is also committed to saving the planet, reducing waste generation through their eco-friendly production processes.

And here’s the real kicker: these laser cutters can handle complex jobs without expensive customization dies. Talk about versatility and cost-effectiveness.

So, if you’re a business looking to make waves in a competitive market, take a page from AP Precision Metals’ book. With the right tools and smart investments, you too can achieve greatness.

FAQs in Relation to Is Laser Cutting Cost Effective

Let’s find out.

How can laser cutting costs be reduced?

- Optimize material usage to minimize waste.

- Invest in high-quality laser cutting equipment for efficiency.

- Automate processes to save time and labor costs.

- Shop around for competitive pricing from different laser cutting service providers.

- Consider outsourcing to countries with lower labor costs.

- Implement preventive maintenance to avoid costly breakdowns.

- Train employees to operate the laser cutting machines effectively.

- Utilize software solutions to optimize cutting paths and reduce material usage.

- Explore alternative cutting methods that may be more cost-effective for specific applications.

- Stay up to date with industry trends and advancements to identify new cost-saving opportunities.

So, with these tips, laser cutting can be both cost-effective and efficient.

Conclusion

Laser cutting: the manufacturing industry’s money-saving superhero.

With CNC-controlled machines, accuracy and efficiency are a match made in heaven.

Save on production costs and say goodbye to waste material with laser cutting.

Versatility is the name of the game, making laser cutters the ultimate cost-effective solution.

When it comes to manufacturing, laser cutting is the smart choice for savvy business owners.