THE GO-TO FOR FULL-SCALE METAL SOLUTIONS

TRUST A LOCAL SUPPLIER PREPARED TO GROW WITH YOU

INTEGRATED MANUFACTURING THAT SCALES AS YOUR BUSINESS EVOLVES

Mid-to-high volume. Domestic. Lean.

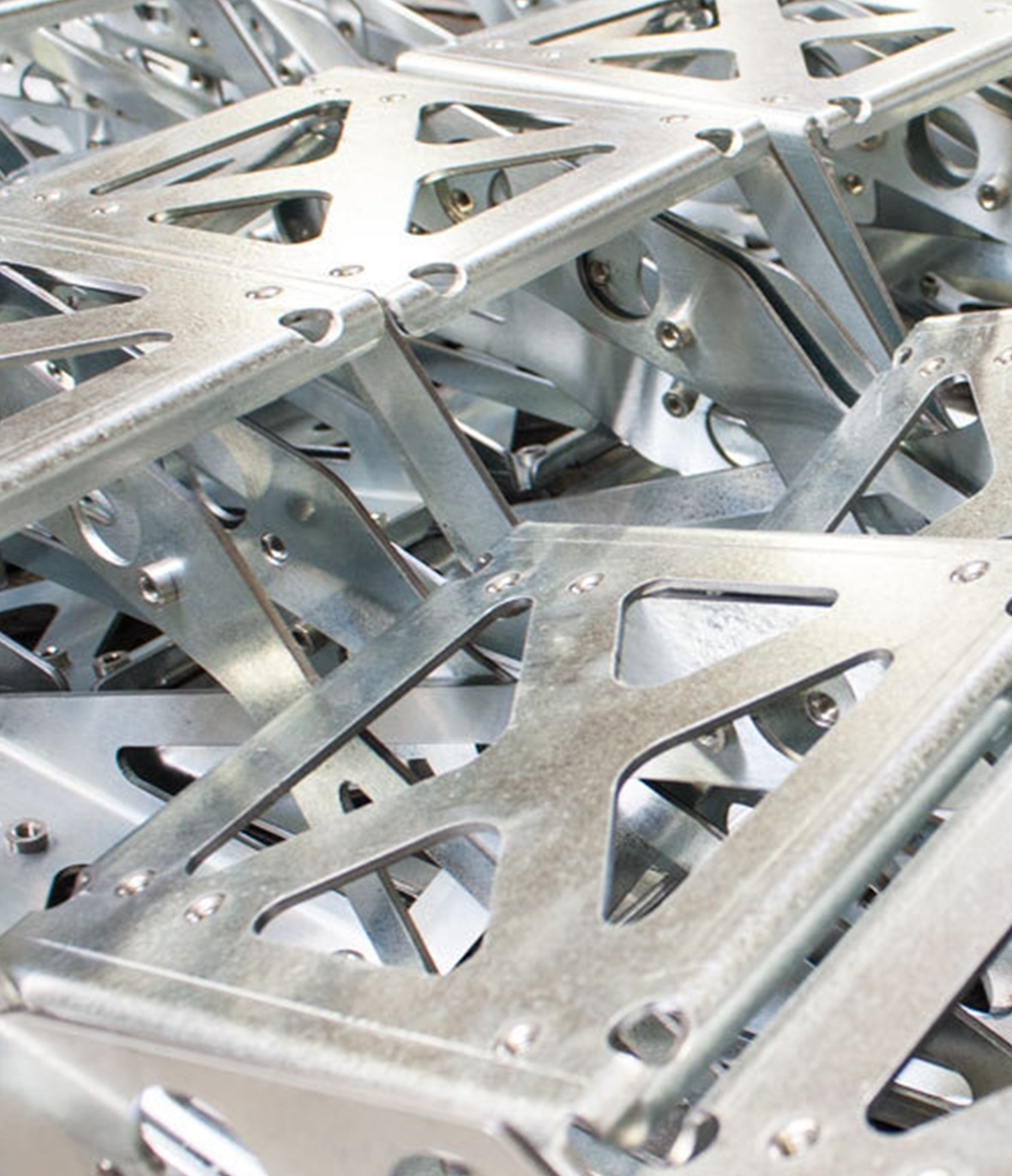

FABRICATION

We focus on annual volumes of 100-10,000 EAU. Our proven manufacturing systems are automated, yet flexible, allowing us to ramp up production quickly, achieve pricing competitive with stamping, and put in quick cut-in revision changes without incurring tooling costs. Our customer products utilize metals ranging from thin sheet (20GA) to medium plate (1.5’’). Manual and semi-automated cells are available for laser cutting, punching, bending, welding, and hardware insertion.

READ MORE

CUTTING

Our industry-leading specialized machinery enables us to process a wide range of metal alloys and thicknesses, fabricating products requiring multiple subsequent processes, or simpler, high-volume flat parts as well. We also employ 2-D fiber lasers, punch presses, and automated bandsaws to produce complex, high-volume, high-precision parts.

WELDING

Our senior welders carry a range of AWS weld certifications specific to the needs of our customers. We use both robotic weld cells and collaborative robots to improve production quality and reduce the costs of labor.

PAINTING & FINISHING

Finish coatings are essential to the end user’s product experience. Our in-house processes include powdercoat and Linex. Keeping those processes in-house allows us to maintain quality, reduce lead times, and limit costs. If silkscreen, laser etching, passivation, plating, anodizing, chromate, zinc, or black oxide are required we work with trusted suppliers in our region.

ASSEMBLY & KITTING

We offer a wide range of heavy material handling equipment which are all ready to be utilized to meet your product requirements. By shifting the early stages of your assembly to AP Precision, your resources can be focused on electrical assembly and function testing prior to shipment. For products that don’t require any electrical assemblage or testing, we also provide complete kitting, labeling, and packaging of your products.

BUSBAR

We’re Experts in Busbar. AP Precision is a national leader in aluminum busbar manufacturing. The main advantages of aluminum busbars are their lower cost compared to copper and their lighter weight, which simplifies handling and installation, while also providing sufficient conductivity for most electrical applications when designed for large cross-sectional areas. With our range of machinery and skilled operators, we are able to quickly cut and bend even the most complex profiles. Our state of the art 40,000 sq. ft. factory in San Diego, CA, has capability to run your product for a quick turnaround or best pricing. Test our Metal.

OEM SUPPLY

We lead the market in manufacturing flexibility. Our experienced teams of quality engineers ensure that production methods are conducted to the highest possible standards of quality and efficiency. Ample machine redundancy gives us the additional capacity to quickly shift products from prototype to high production and make changes as required.

QUALITY ASSURANCE

Our Quality Department upholds the standards set by AP Precision leadership to serve our customers. We believe a successful Quality Management System is about effective follow-through. Truly robust quality management demands a systematic approach to achieving quality objectives, process improvements, and continual operational advances.

RELY ON OUR EXPERIENCE TO LIFT YOUR PRODUCT LINE

AP Precision Metals has been in the business for over 20 years

You can lean on the complete industry knowledge we’ve developed to help you achieve production at greater speed, with more dependability, and at extremely competitive rates. Our seasoned staff and skilled technicians can be depended upon to provide creative and advanced solutions to the complex manufacturing questions facing your business.

To achieve the most efficient possible services and our best-in-class customer experience, we leverage innovative methods and the latest technology solutions. If there’s a better way to get it done, we’ll be there to let you know so you don’t sacrifice quality.

OUR PARTNERS

Some of the brands we are proud to call partners:

FIND YOUR TEAM, BUILD YOUR FUTURE

CONTACT OUR TEAM

CONTACT

CONTACT OUR TEAM

Enlist a long-term partner dedicated to the supply of the high quality metal fabrication you need. We invest in your company's growth through innovation, always working to offer the equipment and advice best suited to your production requirements.

JOIN OUR TEAM

JOIN OUR TEAM

Our organization of professionals values diversity and collaboration. We pride ourselves on the ability to provide forward-thinking solutions for our clients. We are always in search of employees who share the same passion for top-quality production.