Selecting the right material for industrial projects is one of the most critical decisions engineers and fabricators make, especially when designing for harsh environments. The performance difference between a successful installation and a failed…

Read More

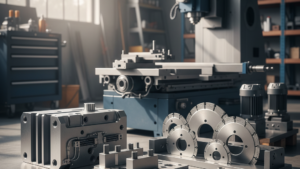

Preventative Industrial Maintenance: Essential Winter Welding Checks for Machinery

Winter can be one of the toughest seasons for industrial equipment—especially for machinery involved in welding operations. Cold temperatures, moisture, and fluctuating thermal conditions place extra stress on mechanical systems, electrical components, and weld integrity….

Read More

Scheduling Shop Work Before the New Year: Save Time and Money

As the end of the year approaches, many industrial operations begin to wind down or pause for holiday schedules and annual maintenance. But while the calendar slows, this period presents a strategic opportunity: scheduling your…

Read More

Custom Metalwork Ideas for Industrial Maintenance Over Winter

Winter provides a strategic window for industrial facilities to focus on preventive maintenance, upgrades, and infrastructure improvements. With cooler temperatures and lighter production schedules, it’s the perfect season to tackle metalwork projects that often get…

Read More

Why December Is Perfect for Planning Welding and Fabrication Projects

As the year winds down, many businesses begin to shift their focus from active production to strategic planning—and in the welding and fabrication industry, December is an ideal time to lay the groundwork for a…

Read More

What to Look for in a Welding and Fabrication Company Before the New Year

As the new year approaches, many businesses are re-evaluating their vendors, suppliers, and production partnerships. One critical area to assess is your welding and fabrication provider. Whether you are in manufacturing, construction, aerospace, defense, or…

Read More

How Quality Sheet Metal Fabrication Can Save Money on Winter Repairs

As winter brings harsh weather, freezing temperatures, snow, and ice, infrastructure and components across many industries are put to the test. Poorly fabricated metal parts often fail when durability matters most. This results in costly…

Read More

Why November Is the Best Time to Schedule Custom Welding & Fabrication Projects

As the calendar moves toward the end of the year, many companies begin wrapping up budgets and evaluating their final projects. For those in need of custom welding and fabrication services, November offers a key…

Read More

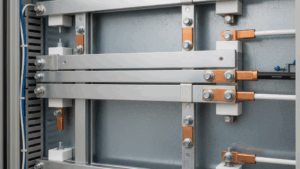

Fall Safety Inspections: Identifying Weak Points in Aluminum Busbars

Aluminum busbars play a crucial role in modern electrical distribution systems. Known for their strength-to-weight ratio, conductivity, and cost-effectiveness, aluminum busbars are widely used across industries. However, like any integral electrical component, they require ongoing…

Read More

September Checklist: Inspecting and Replacing Worn Aluminum Busbars Before Q4

As the third quarter draws to a close, it’s the perfect time to evaluate the performance and condition of your electrical systems. For many industrial, commercial, and energy operations, aluminum busbars are the backbone of…

Read More