Do small businesses use contract manufacturing? The answer is an emphatic affirmative, and for good rationale. Contract manufacturing offers numerous benefits to companies of all sizes, particularly those in the early stages of growth or with limited resources.

In this blog post, we will explore the advantages that come with employing contract manufacturers for small businesses looking to manufacture metal components. We’ll delve into cost savings through reduced overhead expenses and improved scalability in production processes.

Furthermore, we will discuss the various services offered by these specialized manufacturers such as design support, quality control testing, and early product support. Additionally, you’ll learn about establishing successful collaborations with contract manufacturers through clear communication channels and customer-centric planning.

Finally, we will touch upon protecting your intellectual property through non-disclosure agreements (NDAs) when working with ISO 9001-certified contractors as well as managing inventory using advanced software solutions like Deskera ERP for real-time insights on supply chain management. So do small businesses use contract manufacturing? Absolutely – read on to discover how it can benefit your company too!

Table of Contents:

- Benefits of Contract Manufacturing for Small Businesses

- Cost Savings through Reduced Overhead Expenses

- Improved Scalability and Flexibility in Production

- Services Offered by Contract Manufacturers

- Protecting Intellectual Property Through NDAs

- Do Small Businesses Use Contract Manufacturing?

- Managing Inventory with Contract Manufacturers

- Do Small Businesses Often Use Contract Manufacturing?

- Why Do Companies Use Contract Manufacturing?

- Who Uses Contract Manufacturing?

- What Is an Example of Contract Manufacturing in Business?

- Why Is Contract Manufacturing Becoming More Popular?

- Conclusion

Benefits of Contract Manufacturing for Small Businesses

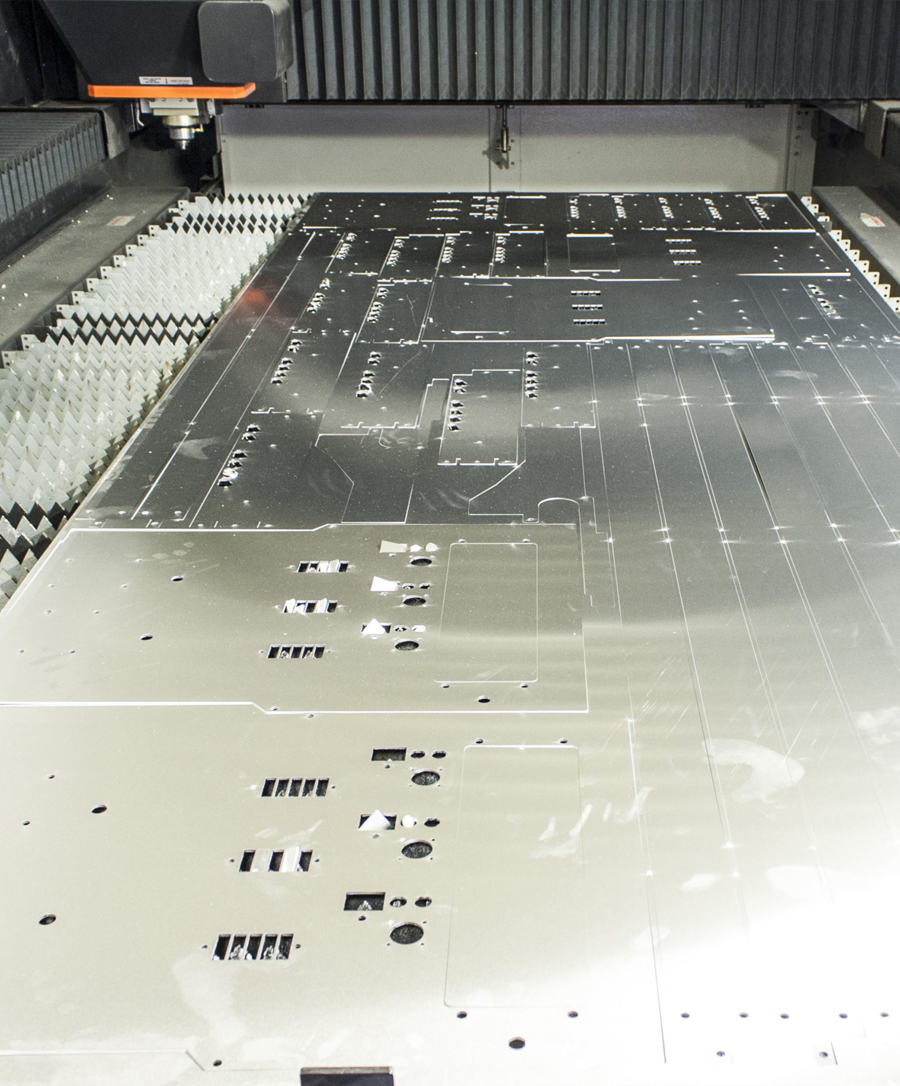

Contract manufacturing offers numerous advantages to small businesses, especially those producing metal components. By outsourcing production tasks, companies can save money and resources while focusing on their core competencies without worrying about acquiring necessary materials or equipment. This approach also allows them to scale up operations more efficiently.

Cost Savings through Reduced Overhead Expenses

Small businesses often struggle with high overhead costs when it comes to manufacturing. Partnering with a contract manufacturer helps reduce these expenses by eliminating the need for costly machinery, maintenance, and labor. As a result, companies can allocate their budget towards other essential aspects of their business.

Improved Scalability and Flexibility in Production

Contract manufacturers, like AP Precision, provide flexible production capabilities that enable small businesses to adapt quickly to market changes or customer demands. They can easily increase or decrease output as needed without investing in additional infrastructure or personnel themselves. This level of agility is crucial for maintaining competitiveness in today’s fast-paced industries.

The cost savings and scalability benefits of contract manufacturing make it an attractive option for small businesses looking to reduce overhead expenses while increasing their production capabilities. Contract manufacturing can also offer design and engineering assistance to guarantee that products are made with the utmost quality.

Services Offered by Contract Manufacturers

One of the main advantages of working with a contract manufacturer (CM) is that they offer flexibility in terms of services provided. They are adaptable enough to cater not only to traditional manufacturing needs but also provide design and engineering services that conventional manufacturers may not be able to afford or deliver effectively.

Design and Engineering Support

Contract manufacturers can assist small businesses with product development, offering expertise in designing metal components for optimal functionality and manufacturability. By collaborating closely with CMs during the design phase, companies can ensure their products meet industry standards while reducing production costs.

Quality Control Testing and Early Product Support

In addition to design assistance, contract manufacturers often provide comprehensive quality control testing throughout the production process. This includes material analysis, dimensional inspection, and functional testing to guarantee high-quality end results. Furthermore, CMs can offer early product support such as prototyping or pilot runs before full-scale manufacturing begins.

Contract manufacturing offers a wide range of services, from design and engineering support to quality control testing and early product support. To ensure successful collaboration with contract manufacturers, it is important for companies to establish clear communication channels as well as customer-centric planning strategies.

Establishing Successful Collaboration with Contract Manufacturers

To ensure successful collaboration between small businesses and contract manufacturers, it is crucial for both parties to establish clear communication channels right from the beginning stages of partnership development. Companies should focus on being customer-centric by thinking two to three steps ahead when planning projects with contract manufacturers – this will help bridge any gaps during project execution phases.

Clear Communication Channels

Maintaining open lines of communication is essential in fostering a strong working relationship between your business and the contract manufacturer. Make sure to discuss expectations, timelines, and deliverables upfront to avoid misunderstandings or delays later on.

Customer-Centric Planning

- Identify Goals: Clearly outline your objectives for partnering with a contract manufacturer. This may include cost savings, improved production capacity, or access to specialized expertise.

- Create Detailed Specifications: Provide comprehensive documentation detailing product requirements, materials needed, quality standards expected, as well as any other relevant information that can guide the manufacturing process effectively.

- Select Appropriate Partners: Choose a contract manufacturer who has experience in producing similar metal components and shares your commitment towards delivering high-quality products within stipulated timeframes (AP Precision, for example).

Contract manufacturing is a popular option for small businesses looking to lower costs and generate revenue. Contract manufacturers make it possible for companies to outsource the production process, allowing them to focus on product development and other core competencies. This is especially beneficial for start-up companies that may not have the manufacturing knowledge or resources to produce their products in-house.

Large companies also benefit from contract manufacturing as it allows them to scale production without investing in additional equipment or labor costs. Contract manufacturers can also provide expertise in areas such as computer-aided design, production scheduling, and quality control.

However, it is important to note that there are potential risks associated with contract manufacturing. Intellectual property concerns may arise, and there is a risk of losing control over the production process. It is essential to choose a reputable contract manufacturer and establish clear guidelines for quality control and intellectual property protection.

Overall, contract manufacturing can be a profitable business strategy for small businesses and large companies alike. By partnering with a reliable contract manufacturer, businesses can focus on product development and marketing while leaving the production process to the experts.

To ensure a successful collaboration with contract manufacturers, it is important to establish clear communication channels and have customer-centric planning. To protect intellectual property from potential risks, non-disclosure agreements should be put in place when working with ISO 9001-certified contractors.

Protecting Intellectual Property Through NDAs

One of the critical aspects of collaborating with contract manufacturers is safeguarding your company’s intellectual property (IP). Non-disclosure agreements (NDAs) play an essential role in protecting sensitive information from being leaked to competitors or the public, ensuring that businesses can maintain their competitive edge in the market. By signing an NDA, both parties agree not to disclose any confidential information shared during their partnership.

Importance of Non-Disclosure Agreements

- Maintains confidentiality and trust between partners.

- Prevents unauthorized sharing of trade secrets and proprietary knowledge.

- Deters potential IP theft by clearly outlining legal consequences for violations.

Working with ISO 9001-Certified Contractors

Besides implementing NDAs, partnering up alongside ISO 9001:2015 certified contractors ensures high-quality end results, thus increasing overall profitability margins substantially over longer-term durations. These certifications demonstrate a commitment to quality management systems and continuous improvement processes, providing small businesses with added confidence in their chosen contract manufacturer’s capabilities.

Protecting intellectual property through NDAs is essential for companies looking to contract out their manufacturing, as it ensures that sensitive information remains confidential. Furthermore, electronic contract manufacturing offers several advantages such as cost control and reduced pricing due to its expertise in electronics production.

Do Small Businesses Use Contract Manufacturing?

Small businesses often face challenges when it comes to manufacturing their products. They may lack the necessary manufacturing knowledge, labor costs may be too high, or they may not have the resources to invest in the manufacturing process. This is where contract manufacturing comes in.

Contract manufacturing is the process of outsourcing the production of a product to a third-party company. Contract manufacturers make products according to the specifications provided by the hiring company. This allows small businesses to focus on product development, marketing, and generating revenue, while the contract manufacturer takes care of the production process.

Many small businesses use contract manufacturing to lower costs and increase efficiency. By outsourcing production to a contract manufacturer, small businesses can save on labor costs, as they do not have to hire and train their own production staff. Additionally, contract manufacturers can often produce products at a lower cost due to economies of scale.

Contract manufacturing is not just for small businesses. Large companies also use contract manufacturing to reduce costs and streamline their supply chain. By outsourcing production to a contract manufacturer, large companies can focus on their core competencies and leave the complexities of production to the experts.

However, there are some potential drawbacks to using contract manufacturing. One concern is the protection of intellectual property. Small businesses must ensure that their product idea and computer-aided design (CAD) files are protected before sharing them with a contract manufacturer. Additionally, small businesses must work closely with the contract manufacturer to ensure that the production schedule and quality control meet their standards.

In conclusion, contract manufacturing can be a profitable business strategy for small businesses looking to reduce costs and increase efficiency. By outsourcing production to a contract manufacturer, small businesses can focus on their core competencies and leave the complexities of production to the experts.

Electronic contract manufacturing provides a cost-effective solution to companies looking for expertise in electronics production. By managing inventory with the help of contract manufacturers and utilizing Deskera ERP software solutions, businesses can gain real-time insights into their operations that enable informed decision making.

Managing Inventory with Contract Manufacturers

One tool that can help small businesses manage inventory effectively when working with contract manufacturers is Deskera ERP software solutions. This platform enables users to keep track of all relevant data points such as stock levels, lead times, and more. By doing so, companies can make informed decisions about future orders based on real-time insights derived through accurate record-keeping processes.

Utilizing Deskera ERP Software Solutions

Inventory administration is an essential piece of the production cycle for associations of all sizes. With Deskera’s user-friendly interface and comprehensive features, companies can streamline their supply chain operations while ensuring optimal resource allocation at every stage of production.

Real-Time Insights for Informed Decision-Making

- Data accuracy: Accurate information allows companies to plan better by forecasting demand patterns and adjusting production schedules accordingly.

- Labor cost reduction: Automated systems like Deskera reduce manual labor costs associated with inventory tracking and management tasks.

- Risk mitigation: Real-time monitoring helps identify potential issues early on, enabling swift corrective actions before they escalate into larger problems impacting overall business performance.

Do Small Businesses Often Use Contract Manufacturing?

Yes, many small businesses utilize contract manufacturing to reduce overhead costs, increase production scalability, and access specialized expertise. This allows them to focus on core competencies like product development and marketing while benefiting from the resources of an established manufacturer.

Why Do Companies Use Contract Manufacturing?

Companies choose contract manufacturing for various reasons such as cost savings, improved flexibility in production capacity, access to advanced technology and equipment, design support, quality control testing, and reduced time-to-market. It enables them to stay competitive without investing heavily in their own infrastructure.

Who Uses Contract Manufacturing?

A wide range of industries rely on contract manufacturers, including automotive, aerospace & defense, consumer electronics & appliances (CEA), medical devices & pharmaceuticals (MDP), industrial machinery & equipment (IME), telecommunications & networking gear (TNG) among others.

What Is an Example of Contract Manufacturing in Business?

An example of a company using contract manufacturing is Apple Inc., which outsources the assembly of its iPhones and other products to Foxconn Technology Group. By doing so, they can leverage Foxconn’s large-scale production capabilities while focusing on innovation and design aspects themselves.

Why Is Contract Manufacturing Becoming More Popular?

Contract manufacturing has gained popularity due to globalization, increasing competition, advances in technology, and shorter product life cycles that require rapid scaling of production capabilities. It enables companies to stay agile, minimize risks, and focus on their core competencies while leveraging the expertise and resources of specialized manufacturers.

Conclusion

Small businesses can benefit greatly from contract manufacturing, as it allows for cost savings and improved scalability in production. Contract manufacturers offer a range of services, including design and engineering support, quality control testing, and early product support.

To establish successful collaboration with contract manufacturers, clear communication channels and customer-centric planning are essential. It’s also important to protect intellectual property through non-disclosure agreements and work with ISO 9001-certified contractors. Electronic contract manufacturing offers additional advantages such as cost control and expertise in electronics production while managing inventory is made easier by utilizing Deskera ERP software solutions for real-time insights.

In conclusion, small businesses can indeed use contract manufacturing to generate revenue through lower costs while maintaining the quality of their finished products. If you’re looking for a reliable partner in metal component manufacturing that offers high-quality products at competitive prices backed by excellent customer service, visit AP Precision Metals.