Welcome to AP Precision Metals! In this guide, we delve into the essentials of aluminum busbars, fundamental components in electrical systems known for their efficiency and reliability. Understanding these crucial elements and their applications can significantly enhance electrical connectivity and performance. Discover what aluminum busbars are, their key benefits, and why they are integral in modern electrical infrastructures.

What is an Aluminum Busbar and Its Role in Electrical Systems

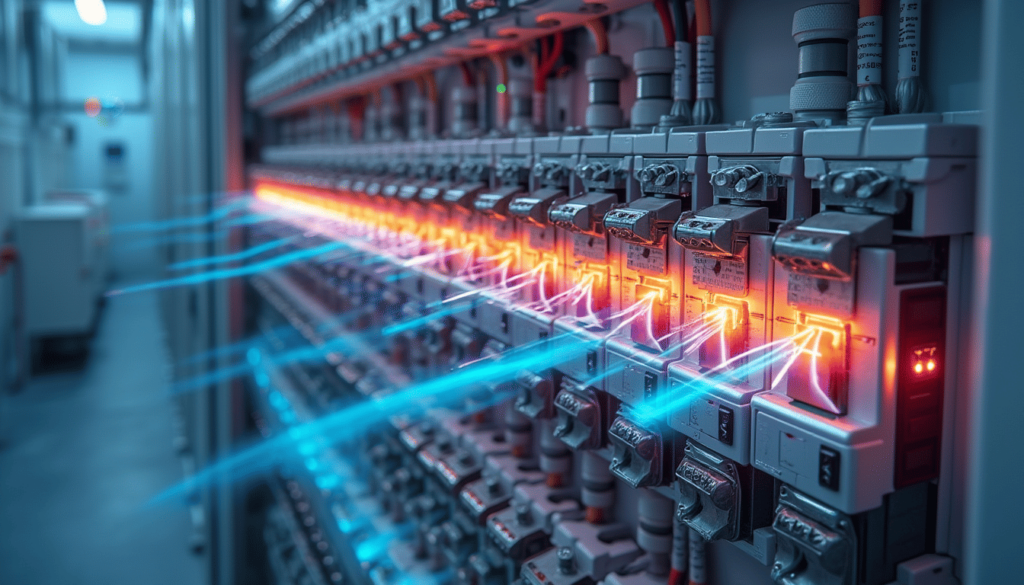

Understanding the significance of aluminum busbars in modern electrical systems is crucial for anyone engaged in the field of power distribution and industrial applications. An aluminum busbar is an essential component that functions as an electrical conductor. It is especially beneficial in distribution systems where efficiency and reliability are paramount. Made from aluminum, these busbars leverage aluminum’s malleability, which allows for easier fabrication and bending, a key advantage in complex electrical configurations.

An aluminum busbar, also referred to as an aluminum bus bar, serves as a critical link in the transmission and distribution of electrical power. It is the backbone of power distribution systems, making aluminum busbars indispensable in both commercial and industrial settings. One of the inherent properties of aluminum is its excellent conductivity. This makes aluminum bus significant in reducing energy losses, thus enhancing the overall efficiency of the distribution systems. Moreover, aluminum’s lightweight nature makes the installation process simpler and more cost-effective compared to its copper counterparts.

When you are discussing aluminum busbars, it’s important to recognize their versatility. Aluminum’s malleability allows for bending and shaping without compromising the structural integrity of the busbar systems. This feature is particularly advantageous for custom installations where space constraints are a concern. Additionally, aluminum’s natural resistance to corrosion ensures a longer lifespan for the products, which is a vital consideration in both indoor and outdoor applications.

Aluminum busbars can be found in a wide range of applications, from small-scale consumer electronics to large industrial power distribution networks. These busbars are important components in electrical panels, switchgear, and transformer connections, underscoring their critical role in the overall functioning of electrical systems. The ability to carry substantial current loads with minimal voltage drops makes aluminum bus products highly reliable and efficient.

It is also worth noting that the environmental benefits of using aluminum busbars cannot be overlooked. Aluminum is a recyclable metal, making it a sustainable choice for reducing the carbon footprint of electrical systems. This is an important aspect, especially in today’s context of growing environmental awareness and regulatory requirements.

In conclusion, an aluminum busbar is more than just an electrical conductor; it is a strategic component in distribution systems that you should consider for any electrical project. From its role in efficient power distribution to its ease of installation and sustainability, aluminum busbars offer a host of benefits that make them a preferred choice in the industry. Understanding these advantages clarifies why these aluminum busbar systems are important in various applications, ensuring longevity, efficiency, and environmental stewardship.

Benefits of Aluminum Busbars in Energy Distribution

Aluminum busbars play a crucial role in modern energy distribution systems, offering numerous benefits to both commercial and residential applications. One of the most significant advantages is that aluminum is regarded as the most sustainable metal on busbar trunking conductors. Its sustainability is driven by its ability to be recycled without loss of properties, making it an environmentally friendly option for power distribution systems. Additionally, aluminum’s malleability allows for easier fabrication and bending, offering designers and engineers increased flexibility during the installation process.

One of the primary benefits of using an aluminum busbar in energy distribution is its excellent conductivity, which is critical for efficient power transmission. Aluminum’s high conductivity ensures that energy losses are minimized, enhancing the overall efficiency of distribution systems. This is particularly important in applications such as solar energy, where every bit of energy efficiency can contribute to greater overall performance.

The lightweight nature of aluminum also contributes to its suitability for use in an aluminum busbar. It is significantly lighter than other metals like copper, making it easier to handle and install. The reduced weight also means that support structures and mounting hardware can be less robust, leading to cost savings in the overall system design. Moreover, lighter busbars that are easier to install can translate into reduced labor costs and shorter installation times.

Another key advantage is the cost-effectiveness of aluminum busbars. Aluminum is generally more affordable than other conductive metals, which can lower the initial material costs for power distribution systems. The combination of lower material costs, reduced labor, and installation expenses, along with the sustainability factor, makes aluminum busbars an attractive option for many applications.

Aluminum busbars offer excellent durability and resistance to corrosion, which ensures a long lifespan and reliability in various environmental conditions. This makes them particularly suitable for outdoor installations or areas with high exposure to the elements. The longevity and reliability of aluminum busbars add another layer of cost-effectiveness, as they require less frequent replacement and maintenance compared to other materials.

In conclusion, aluminum busbars offer a multitude of benefits for energy distribution systems. Aluminum’s malleability allows for easier fabrication and bending, enhancing the design flexibility. Its high conductivity contributes to overall energy efficiency, and the lightweight nature simplifies handling and installation. Additionally, the cost-effectiveness and sustainability of aluminum make it a preferred choice for modern power distribution needs. Whether used in solar systems or other energy applications, aluminum busbars provide a reliable, efficient, and environmentally friendly solution for dynamic energy distribution requirements.

Conductivity and Efficiency of Aluminum Busbars

Understanding the conductivity and efficiency of aluminum busbars is crucial for anyone involved in power distribution and electrical systems. Aluminum is regarded as the most sustainable metal on busbar trunking conductors, and it offers significant advantages in terms of conductivity and efficiency. One primary attribute of aluminum busbars is their excellent electrical conductivity. Although it’s not as high as copper, aluminum’s conductivity is still capable of effectively supporting various energy distribution needs. This efficiency, combined with its lightweight nature, makes aluminum busbars a popular choice in both commercial and industrial applications.

The key to aluminum busbars’ efficiency lies in their design and the inherent properties of aluminum. Aluminum, as an electrical conductor, delivers a unique combination of strength, conductivity, and flexibility. Because of aluminum’s malleability, it allows for easier fabrication and bending, which is particularly beneficial in the tight and complex configurations often found in modern electrical systems. This malleability ensures that aluminum busbars can be tailored to meet specific needs without compromising performance or reliability.

Many data centers and battery storage facilities are increasingly turning to aluminum busbars for their power distribution needs. Aluminum is the third most abundant element in the Earth’s crust, making it both affordable and accessible for widespread use. Its economic advantages extend to reduced installation costs, as aluminum busbars are lighter and therefore easier to install and handle compared to heavier alternatives like copper. Additionally, aluminum’s longevity and corrosion resistance further enhance its efficiency and reliability in harsh conditions.

In terms of energy conservation, aluminum busbars stand out. They offer low electrical resistance, which translates to minimal energy loss during transmission. This high efficiency makes aluminum busbars an excellent choice for both large-scale electrical systems and smaller, more precise applications such as battery wiring and wire harnesses. The environmental benefits also can’t be overlooked; aluminum’s sustainability and recyclability complement its energy-saving properties, reducing the overall ecological footprint of electrical installations.

In summary, the efficiency and conductivity of aluminum busbars are well-documented, making them a superior option for various power distribution needs. By leveraging aluminum’s malleability, we can customize busbars with ease, ensuring optimal performance and energy efficiency. If you’re considering upgrading your electrical systems, choosing aluminum busbars can significantly enhance both performance and sustainability. At AP Precision Metals, we offer an extensive range of aluminum busbars designed to meet diverse requirements, ensuring top-tier quality and reliability in all our products.

Different Types of Busbars and Their Applications

In the realm of electrical distribution systems, busbars play a crucial role in ensuring efficient power distribution and reliable performance. Understanding the different types of busbars and their applications is essential for making informed choices tailored to specific needs. At AP Precision Metals, we offer a comprehensive range of bus bar products designed to meet varied industrial requirements. These include aluminum busbars, copper busbars, and even combinations that harness the unique benefits of each material.

Aluminum Busbars: Aluminum busbars are widely recognized for their lightweight properties and excellent conductivity. These busbars are typically preferred where weight reduction is critical without compromising on performance. Aluminum bus is often used in electrical conductor applications in industries like automotive, aerospace, and power generation. The unique characteristics of aluminum that make it highly efficient in heat dissipation enhance its suitability in compact systems and confined spaces.

Copper Busbars: Copper busbars, on the other hand, offer superior conductivity which is essential in high-performance electrical distribution systems. Despite its heavier weight, copper outperforms aluminum in terms of electrical conductivity and thermal performance. Thus, in scenarios where maximum efficiency and reliability are paramount, copper busbars are the preferred choice.

Combination Busbars: In some advanced applications, a combination of aluminum and copper busbars is used to take advantage of the strengths of both materials. This hybrid approach can provide a balanced solution that offers both the lightweight benefits of aluminum and the high conductivity of copper, optimizing performance in a variety of industrial applications.

The versatility of bus bar systems also allows for their integration into various electrical distribution systems. Whether utilized in switchgear, control panels, or distribution boards, busbars must be selected based on specific technical requirements and environmental considerations. Different types of busbars, such as flat bar, round bar, and flexible busbars, can be employed depending on the space constraints and electrical load demands.

Moreover, the material used in busbars extends beyond just aluminum and copper. Stainless steel busbars and hot-dipped galvanized busbars are increasingly finding applications in harsh industrial environments due to their robustness and resistance to corrosion. As industries continue to demand higher reliability and durability, these materials offer extended service life and reduced maintenance requirements.

At AP Precision Metals, we understand the critical importance of choosing the right type of busbars for specific applications. Our expert team can guide you through the selection process, ensuring that your distribution systems integrate seamlessly with the chosen busbars. Whether you require aluminum bus bar solutions for lightweight applications or copper busbars for high-conductivity needs, we are equipped to meet and exceed your expectations with our diverse offering of bus bar systems.

Why You Should Choose Aluminum Busbar for Your Projects

When it comes to selecting the right materials for your electrical projects, it’s crucial to understand the significant advantages that an aluminum busbar can offer. Aluminum busbars are an excellent option for power distribution systems due to their unique properties. One of the primary reasons to opt for an aluminum bus bar is aluminum’s high conductivity combined with its lighter weight compared to other metals. These characteristics make aluminum a preferred choice for long-span bus applications, where weight reduction can result in substantial cost savings.

Another notable feature of aluminum busbars is their remarkable malleability. Aluminum’s malleability allows for easier fabrication and bending, which simplifies the installation process. This ease of installation can be particularly beneficial in applications where complex geometries and precise fitting are required. Furthermore, the bus bar’s flexibility allows for modifications in design or rerouting without significant effort or cost.

Aluminum busbars also exhibit high resistance to corrosion, making them ideal for use in harsh environments. This corrosion resistance enhances the longevity of the busbar, reducing maintenance costs and ensuring a reliable power distribution system over the long term. With these benefits, it’s easy to understand why industries ranging from renewable energy to transportation frequently choose aluminum as their metal of choice for bus bar applications.

Moreover, aluminum busbars are an environmentally friendly option, as aluminum is highly recyclable. Using recyclable materials in your projects is becoming increasingly important in today’s environmentally conscious world. Employing aluminum that is sustainable not only benefits the environment but can also have positive impacts on your project’s reputation and compliance with green building standards.

In terms of cost-effectiveness, aluminum busbars present a superior option. Aluminum is generally more affordable than other conductive metals like copper. Thus, choosing aluminum busbars can provide significant cost advantages without compromising on performance or reliability. We understand that budget constraints are often a concern, and aluminum busbars can help you maintain financial efficiency while meeting all technical requirements.

In conclusion, the decision to use an aluminum busbar for power distribution projects is supported by a multitude of benefits that bars from ease of fabrication to corrosion resistance, to cost-effectiveness. Choosing aluminum for your bus bars ensures a reliable, durable, and economically advantageous solution, making it a smart choice for any electrical metal products application. By understanding these benefits, you can make a more informed decision that aligns with both your project goals and budget constraints.

At AP Precision Metals, we understand the critical role that aluminum busbars play in the efficiency and reliability of electrical systems. Our expertise in manufacturing high-quality aluminum busbars ensures that your power distribution requirements are met with precision and reliability. Whether you are in need of custom aluminum busbars or standard solutions, our team is dedicated to providing exceptional products and service. Trust AP Precision Metals for all your aluminum busbar needs and experience the benefits of superior performance and durability.