The Role of Aluminum Busbars in Modern Industry

The Role of Aluminum Busbars in Modern Industry

In the rapidly evolving landscape of today’s industry, aluminum busbars have become a vital component of modern electrical systems. Their integration into industrial systems enhances efficiency while significantly reducing costs. Being the material of choice for many industries, aluminum busbars offer an effective way to transmit electrical power across various components. The lightweight nature of aluminum makes it an ideal option for these applications, providing significant advantages over other materials. Furthermore, the use of aluminum busbars results in lower resistance, which is crucial for maintaining optimal performance within the systems. When comparing aluminum to alternative materials, its benefits become evident, offering both durability and cost-effectiveness. As industries continue to prioritize enhanced electrical efficiency, the implementation of aluminum busbars cements their pivotal role, ensuring that modern industrial applications keep up with the demands of progress and innovation.

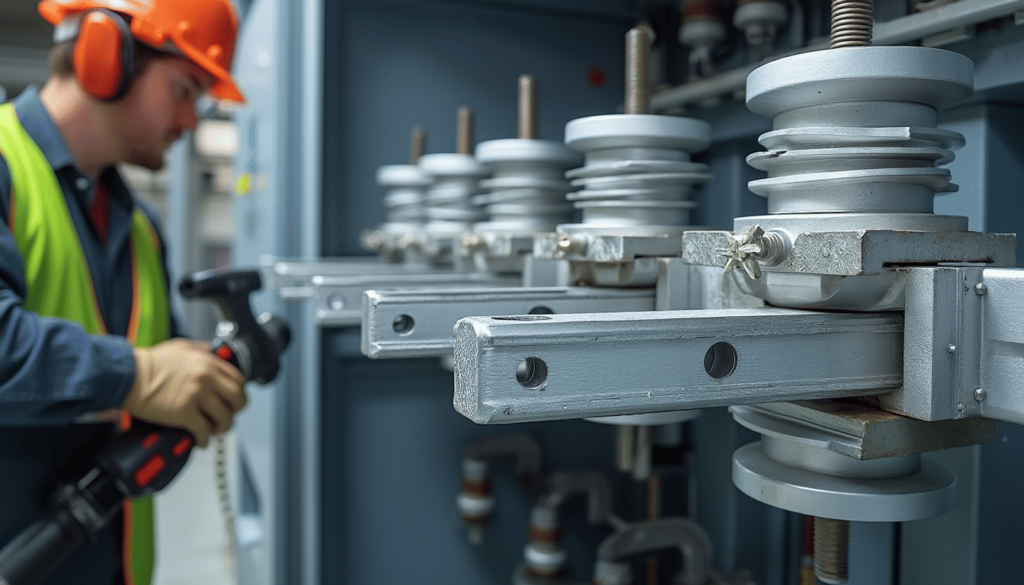

Top Applications of Aluminum Busbars

Aluminum busbars have become one of the essential products in modern industries due to their high conductivity and efficient current transmission capabilities. They’re particularly favored in electric and electronic sectors where reliable power distribution is critical. Among the top applications of aluminum busbars, you’ll find their use in power substations and switchgear units, ensuring high-performance and stable electric connections. Additionally, aluminum busbars are extensively utilized in renewable energy systems, such as photovoltaic and wind installations, where efficiency and sustainability go hand in hand. Modern automotive industries have also embraced them to meet the rising demand for advanced electrical systems, with their lightweight and high conductivity playing a crucial role. The use of aluminum busbars in these top applications signifies their significant impact across various sectors, positioning them as a leading choice in the current electric market.

Understanding the Strength of Aluminum in Busbar Applications

Aluminum busbars are renowned for their unique blend of strength and functionality, making them an ideal choice for various applications. In industries where weight is a critical factor, aluminum’s lightness offers significant advantages over other metals. Its high electrical conductivity ensures efficient power distribution while maintaining flexibility for various design configurations. Moreover, the material’s excellent resistance to corrosion underpins its durability, ensuring long-lasting performance despite harsh environmental conditions. The strength of aluminum contributes to busbar reliability in demanding applications, facilitating the handling of high power loads without compromising safety or efficiency. Aluminum busbars’ electrical properties provide the much-needed conductivity required in modern systems, aligning with industry needs for eco-friendly and lightweight solutions. The combination of strength, weight, and high conductivity makes aluminum an indispensable component in the advanced electrical applications envisaged by today’s industries.

Types of Aluminum Busbars in Current Industries

The types of aluminum busbars in current industries have evolved to cater to a wide range of applications, making them a choice for many sectors. Factors such as conductivity, corrosion resistance, and cost-effectiveness make aluminum the preferred materials for many industries. In the market, you’ll find solid aluminum busbars generally used in power distribution systems due to their excellent capacity to carry current. Hollow and tubular types of aluminum are often chosen for lightweight and flexible application needs, proving advantageous for HVAC systems. The busbars serve as a backbone to electrical distribution, supporting innovative systems in automotive, renewable energy, and telecommunications. At AP Precision Metals, our expert understanding of system integration assures you that our aluminum busbars meet the current applications and future industry requirements.

Factors Influencing Busbar Selection

When choosing the right aluminum busbar for modern industrial applications, various factors must be considered to ensure optimal performance and efficiency. The selection process involves evaluating the strength and weight of materials used, as both are crucial in maintaining the integrity and functionality of electrical systems. Market trends and cost considerations also play a significant role in this choice, as businesses aim to balance quality with budget constraints. Furthermore, efficient systems demand precise busbar selection, emphasizing the need to assess the desired conductivity and thermal characteristics. Aluminum busbars, with their lightweight properties, often surpass other options, offering a favorable strength-to-weight ratio. AP Precision Metals emphasizes these factors, providing top-quality aluminum busbars tailored to diverse applications, enhancing overall efficiency and performance in modern industrial landscapes.

The Significance of Weight in Aluminum Busbar Design

The weight of an aluminum busbar plays a crucial role in its design, as these materials must balance strength and flexibility with efficiency. In various high-performance applications, the careful selection of aluminum busbars can enhance overall system performance. The lightweight nature of aluminum is a key factor that makes it a preferred choice in numerous industries. This weight advantage doesn’t compromise on strength, making aluminum busbars an optimal choice for modern applications. Similarly, their design allows for easy integration, further boosting efficiency. When considering busbar design, understanding the implications of weight is essential. It’s not just about choosing a material, but about optimizing the systems in which it is employed. Thus, weight remains a significant factor in busbar selection, directly impacting the overall efficiency and capability of the system.

Exploring Aluminum Busbar Resistance Characteristics

When examining the resistance characteristics of aluminum busbars, it’s crucial to note their high strength and conductivity. These materials are integral to modern power systems due to their efficient performance. Aluminum, with its remarkable resistance properties, offers significant advantages over other materials. One of the key characteristics of aluminum busbars is their flexibility, which allows for easy installation and adaptation in diverse electric applications. This flexibility doesn’t compromise their efficiency, as they retain high conductivity while minimizing resistance losses. Moreover, aluminum’s light weight and high strength contribute to its efficiency in power distribution. AP Precision Metals recognizes the importance of resistance in aluminum busbars, ensuring that their products are optimized for industrial applications. Understanding these resistance characteristics is essential for industries seeking reliable and effective solutions in power management and electric system design, making aluminum busbars a preferred choice.

Current Applications of Aluminium Busbars

In today’s rapidly evolving power market, the applications of aluminium busbars have become increasingly prevalent due to their high efficiency and versatility. Widely recognized for their lightweight nature and inherent flexibility, aluminium busbars are employed in various electric systems, ensuring reliable power distribution. They’re a popular choice in renewable energy setups, industrial facilities, and data centers, where current consistency and effective materials are crucial. The use of aluminium busbars in electric vehicle charging stations further exemplifies their current significance, bridging the gap between modern transport needs and environmental goals. By integrating aluminum’s inherent efficiency with advanced design principles, industries can leverage these busbars for enhanced performance and sustainability, contributing to a greener future. At AP Precision Metals, we’re committed to providing quality aluminium busbars tailored to meet the specific requirements of your power systems.

Innovative Uses of Aluminum in Modern Industries

Aluminum busbars offer innovative uses in modern industries, leveraging their exceptional conductivity and high efficiency. As flexible products, these busbars are pivotal in applications ranging from electric vehicles to renewable energy systems. Industries demand high-performance solutions, and aluminum is uniquely positioned to meet these expectations. It’s not just about the weight advantage, but also about the metal’s innate ability to conduct electricity efficiently, making it a preferred choice in the electric market. Aluminum’s modern uses reflect its versatility and adaptability, which are crucial for industries focused on sustainable and efficient energy distribution. The use of aluminum in busbars exemplifies how high conductivity and flexibility can be harmoniously combined, driving breakthroughs in various sectors. As industries continue to evolve, the demand for innovative and efficient products will ensure aluminum’s prominent role in modern applications.

Why Aluminum Beats Other Metals in Busbar Applications

Aluminum is increasingly becoming the metal of choice for busbar applications, thanks to its superior properties. Unlike other metals, aluminum offers exceptional conductivity and strength, making it ideal for power distribution systems that demand efficiency and reliability. One of the key advantages of using aluminum busbars is their lightweight nature, which significantly reduces overall system weight, increasing installation flexibility and ease of handling. This inherent efficiency doesn’t compromise performance, as aluminum busbars maintain high conductivity levels, ensuring optimal electric power transfer. Additionally, aluminum busbars are cost-effective, offering significant savings in both material and installation costs. Compared to other metals, the balance of strength and weight provided by aluminum makes it the preferred choice for modern applications across various industries. Thus, aluminum busbars are a compelling solution, balancing performance with reduced costs and enhanced deployment flexibility.

Examining the Importance of Resistance in Metal Busbars

Examining the importance of resistance in metal busbars leads us to explore how these critical components enhance strength and efficiency in modern industries. High resistance levels can hinder the efficient conductivity of electric power, emphasizing the necessity for materials like aluminum, known for its superior conductivity and flexibility. The significance of metal busbars lies in their ability to optimize energy distribution, maintaining a balance between resistance and conductivity. Metal busbars must possess the right resistance attributes to manage electric power without compromising efficiency or strength. AP Precision Metals recognizes that high resistance is detrimental to system performance, hence the focus on developing busbars with an ideal resistance profile. By ensuring that our aluminum busbars provide optimal conductivity while maintaining structural strength, we contribute effectively to the reliability of electric systems in diverse industrial applications.

Aluminium as a Preferred Metal in Modern Applications

Aluminium remains a preferred metal in various modern applications due to its unique combination of properties that make it ideal for numerous industries. In busbar applications, aluminium offers impressive strength and efficiency, making it a top choice among industry professionals. The reduced weight of aluminium compared to other metals contributes to its widespread use, as lighter materials can significantly lower transportation and installation costs. These cost savings, combined with the metal’s inherent flexibility, allow manufacturers to create custom solutions that meet the diverse requirements of modern industries. Furthermore, the versatility of aluminium as a metal ensures it can be easily adapted for a wide range of industrial applications. As industries continue to seek innovative materials and methods, aluminium stands out for its ideal balance of strength, efficiency, and cost-effectiveness in meeting the demands of contemporary engineering challenges.

In conclusion, the versatility and efficiency of aluminum busbars make them indispensable in a multitude of modern industries. AP Precision Metals provides tailored aluminum and aluminium bus bar solutions to optimize energy transmission and distribution across various applications. From automotive to renewable energy, our advanced manufacturing processes and precision engineering ensure reliability and performance. By choosing AP Precision Metals, you leverage cutting-edge technology, unparalleled expertise, and a commitment to sustainability. Explore our diverse range of busbar applications to enhance operational efficacy and achieve sustainable energy solutions in today’s rapidly evolving industrial landscape.