In today’s rapidly evolving manufacturing landscape, technology plays a central role in delivering the speed, consistency, and precision that modern industries demand. Among the most transformative advancements in the metal fabrication sector is robotic welding. At AP Precision, we leverage robotic welding to streamline production, increase output quality, and offer scalable solutions for our customers’ most complex fabrication needs.

As demand for high-quality, cost-effective metal components grows across industries such as aerospace, defense, construction, and commercial electronics, robotic welding has become essential to maintaining both productivity and quality in high-volume and high-precision environments.

What Is Robotic Welding?

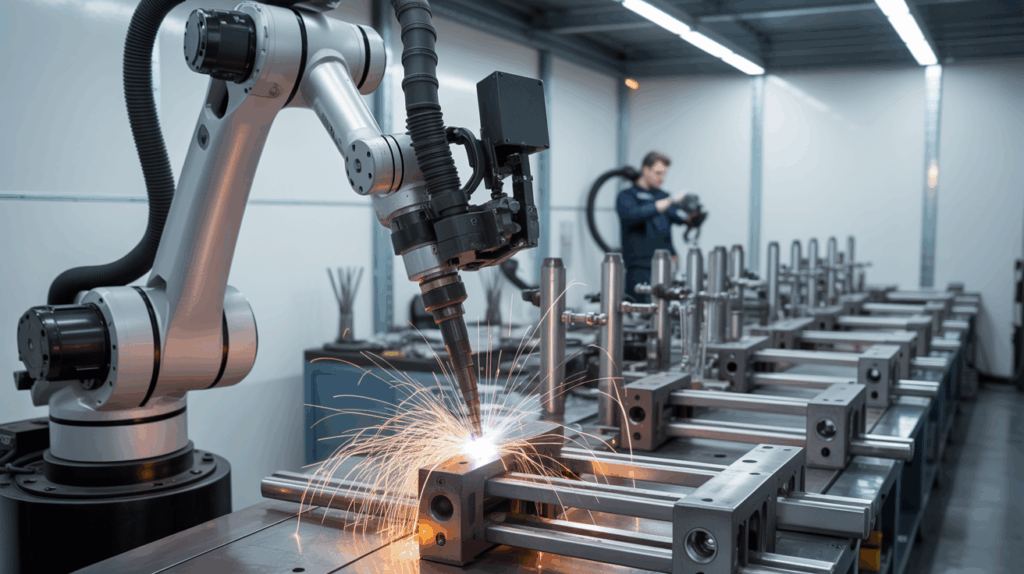

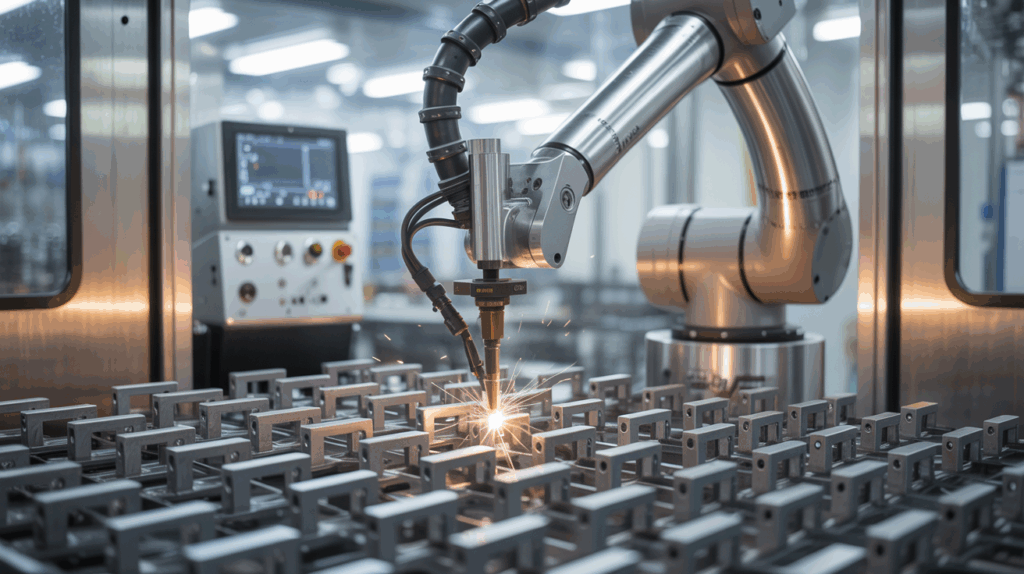

Robotic welding involves the use of programmable, automated machines to perform welding operations. These systems are designed to execute consistent, repeatable welds across a variety of materials, thicknesses, and part geometries. Equipped with sensors, servo motors, and sophisticated programming, robotic welders can handle tasks ranging from spot welding to MIG and TIG welding in both two- and three-dimensional configurations.

Unlike manual welding, robotic systems are not affected by fatigue or inconsistencies—delivering exceptional accuracy and efficiency, even on long production runs. At AP Precision, this technology forms a cornerstone of our approach to modern metal fabrication.

Key Benefits of Robotic Welding at AP Precision

1. Consistent Weld Quality

Manual welding can be prone to human error, resulting in inconsistent welds that require rework or compromise structural integrity. Robotic welding eliminates these variables by following exact programming parameters for each part, ensuring uniformity and strength across every weld seam.

At AP Precision, our robotic welding systems are calibrated to industry standards and rigorously tested, enabling us to produce high-performance welds with a level of consistency that’s nearly impossible to replicate manually.

2. Increased Production Speed

Speed is a significant advantage in high-demand manufacturing environments. Robotic welders can operate continuously without breaks, dramatically increasing throughput. This efficiency allows AP Precision to meet tight deadlines without sacrificing quality—a critical factor for clients who rely on just-in-time (JIT) inventory and rapid product development cycles.

Our robotic cells are designed to handle repetitive welding tasks quickly and with minimal downtime, improving overall production rates while optimizing labor resources.

3. Enhanced Safety

Welding presents a number of workplace hazards, from high heat and UV exposure to fumes and sparks. By using robotic welding systems, AP Precision reduces direct operator exposure to these risks, creating a safer working environment. Our skilled technicians supervise, program, and maintain these systems rather than being exposed to active welding arcs themselves.

As a result, we’re able to maintain strict compliance with workplace safety standards while still delivering complex fabrication work.

4. Lower Operational Costs Over Time

Though the initial investment in robotic welding systems can be significant, the long-term cost savings are substantial. Increased efficiency, reduced rework, minimized material waste, and lower labor requirements all contribute to a lower cost per unit.

At AP Precision, these savings are passed on to our customers—allowing us to offer competitive pricing while maintaining exceptional quality and service reliability.

5. Scalability and Repeatability

Robotic welding is ideal for both high-volume production and batch manufacturing. Once a welding program is developed, it can be used repeatedly with little to no variation, ensuring consistent output even as production scales. This is particularly beneficial for industries where component accuracy is vital to system functionality and regulatory compliance.

Our ability to scale production without compromising on quality makes robotic welding a strategic asset for complex or recurring product lines.

Applications of Robotic Welding at AP Precision

Robotic welding at AP Precision supports a wide array of applications across industries, including:

- Custom enclosures and electronic chassis

- Automotive and transportation components

- Brackets, mounts, and structural frames

- Telecommunications equipment

- Defense and aerospace-grade metal assemblies

Our systems are configured to handle various metals and alloys, including stainless steel, aluminum, and mild steel, ensuring the right welding process is applied to each material type and use case.

Integration With Our Full-Service Fabrication Workflow

At AP Precision, robotic welding is not a standalone offering—it is seamlessly integrated into our full-service metal fabrication capabilities. From CNC machining and laser cutting to powder coating and final assembly, our clients benefit from a vertically integrated process that reduces lead times and boosts accountability at every stage.

This integration allows for optimized part flow, streamlined communication, and enhanced quality assurance throughout the entire project lifecycle.

Why Choose AP Precision for Robotic Welding?

Choosing the right fabrication partner means more than selecting a vendor with the right tools—it means partnering with a team that understands your industry, your specifications, and your deadlines. At AP Precision, we combine cutting-edge automation with decades of hands-on expertise to deliver results that meet the highest expectations for performance, appearance, and durability.

We’re committed to continuous improvement and innovation, which is why we continue to expand our robotic welding capabilities and invest in the latest technology. Whether you require a prototype or full production run, our welding solutions are engineered to perform reliably from day one.

Contact Us to Learn More

Robotic welding is redefining what’s possible in modern metal fabrication—and AP Precision is at the forefront of that transformation. By integrating this advanced technology into our production process, we help our clients achieve greater speed, quality, and efficiency in every project.

Contact us today to learn how our robotic welding services can support your next fabrication project with precision and reliability.