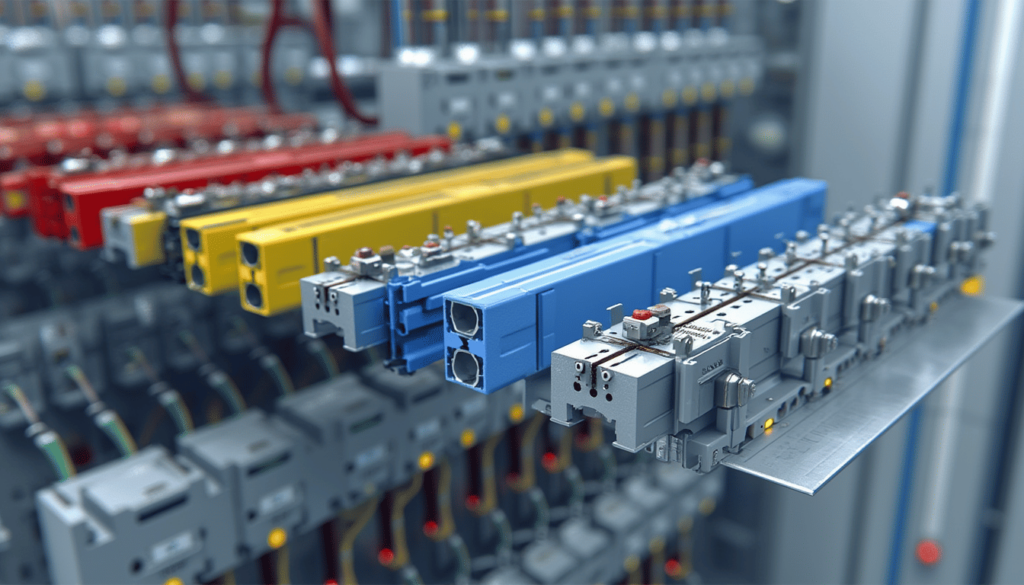

At AP Precision Metals, we understand the critical role that busbars play in electrical systems. Aluminum busbars offer numerous advantages, including cost-efficiency, light weight, excellent conductivity, and corrosion resistance. Discover how incorporating aluminum busbars can enhance the performance and reliability of your electrical infrastructure.

The Advantages of Using Aluminum Busbars in Electrical Systems

When it comes to electrical systems, choosing the right bus bar material is crucial. One popular choice is the aluminum bus bar, thanks to its numerous benefits. Firstly, one of the significant advantages of using aluminum busbars is their excellent electrical conductivity. Aluminum’s conductivity ensures efficient power distribution across the electrical systems, minimizing losses and improving overall system performance. Additionally, the lightweight nature of aluminum busbars makes them easy to install and handle.

Comparatively, aluminum busbars are more cost-effective than their copper counterparts, which is a distinct advantage for large-scale projects where budget constraints are a consideration. This affordability does not compromise quality, as aluminum’s properties still provide exceptional reliability and durability in various electrical system applications. Furthermore, the high corrosion resistance of aluminum busbars ensures longevity, reducing maintenance costs over time.

A key benefit of using aluminum busbar systems is their flexibility. These busbars can be molded and shaped to fit complex electrical designs, making them ideal for custom installations. This flexibility extends to their compatibility with other electrical components, ensuring seamless integration within any electrical system configuration.

In summary, the advantages of using aluminum bus bars in electrical systems are manifold. From the benefits of cost savings and ease of installation to their excellent conductivity and flexibility, aluminum bus bar systems offer a comprehensive solution for various electrical needs. Investing in aluminum busbars ensures a reliable, efficient, and cost-effective performance, making them a practical choice for any power distribution project. Overall, the use of aluminum busbars can significantly enhance the efficiency and robustness of modern electrical systems, reaffirming their status as a wise and effective choice in the industry.

Key Benefits of Aluminum Bus Bars Compared to Copper

When it comes to electrical systems, choosing the right materials for bus bars is crucial for performance and efficiency. One significant advantage of using an aluminum bus bar over a copper busbar is its weight. Aluminum busbars are considerably lighter than their copper counterparts, making them easier to handle and install in any system. This weight advantage can be particularly beneficial in applications where reducing overall system weight is critical.

Another key benefit is the cost-effectiveness of aluminum. Aluminum bus bars are generally less expensive than copper bus bars, which can result in significant savings, especially in large-scale electrical systems. This cost advantage doesn’t come at the expense of performance, as aluminum still offers excellent conductivity and efficiency for most applications.

Aluminum with its natural resistance to corrosion also makes it a durable choice for use in various environments. Unlike copper, which can oxidize over time and require additional maintenance, aluminum busbars are more resistant to environmental factors that can compromise performance. This translates to lower maintenance costs and a longer lifespan for the electrical system.

Additionally, aluminum’s flexibility offers design advantages that copper busbars can’t match. The flexibility of aluminum busbars makes them easier to bend and shape, which can be essential for custom electrical system designs. This attribute provides engineers with more options when designing efficient and compact systems.

Finally, aluminum bus bars are more sustainable, as aluminum is easier to recycle than copper. This contributes to a reduced environmental impact, aligning with many companies’ goals for sustainability. In summary, the benefits of using aluminum busbars over copper busbars in electrical systems include weight, cost, corrosion resistance, flexibility in design, and sustainability. These factors make aluminum the material of choice for modern electrical system applications.

Applications and Products Where Aluminum Busbars Excel

Aluminum bus bars have become a cornerstone in various electrical systems due to their exceptional properties and advantages over traditional materials like steel and copper. One of the primary applications where aluminum busbars excel is in power distribution systems. Due to their excellent conductivity, lightweight nature, and durability, aluminum busbars ensure efficient power transmission with minimal losses. Industries engaged in mass production find aluminum busbars advantageous for these reasons, contributing to cost-efficiency and sustainability over the years.

Aluminum busbars are also prominent in renewable energy systems, such as solar power installations and wind farms. The high conductivity and lighter weight make aluminum ideal for these applications, where minimizing structural load and ensuring long-term reliability are critical. Additionally, in commercial and residential construction, aluminum busbars are increasingly favored for use in electrical panels and switchgear. They offer a significant advantage over copper busbars, thanks to their lower cost and ease of installation.

Beyond these direct electrical applications, aluminum busbars are also used in automotive and aerospace industries. These sectors require lightweight yet strong materials to enhance fuel efficiency and performance, making aluminum busbars an ideal choice. Furthermore, in data centers where sustainability and efficient energy use are paramount, aluminum busbars contribute to reliable and efficient power distribution, thereby supporting high-density computing operations.

AP Precision Metals takes pride in offering top-quality aluminum busbars designed to meet the demands of diverse applications. Our products are crafted to deliver superior performance, whether you’re dealing with complex industrial electrical systems or seeking reliable power solutions for cutting-edge technology applications. With years of expertise in metal fabrication, including aluminum and steel, AP Precision Metals ensures that our aluminum busbars provide unmatched advantages in your electrical systems.

Installation and Maintenance of Aluminum Busbar Systems

At AP Precision Metals, we understand the critical role that proper installation and maintenance of aluminum busbar systems play in ensuring the effective operation of electrical systems. The process of installing an aluminum bus bar requires meticulous planning and precise execution to guarantee optimal conductivity and efficiency. Unlike copper bus bars, aluminum busbars offer advantages such as being lightweight and cost-effective. When you use aluminum busbars, it’s vital to account for the unique properties of aluminum, including its thermal conductivity and expansion characteristics.

Installation begins with selecting the appropriate size and type of aluminum bus bar that meets the specific requirements of your electrical system. Properly preparing the site and ensuring that all components are clean and free from contaminants is crucial. During installation, attention should be given to busbar plating to enhance connectivity and reduce corrosion. AP Precision Metals recommends employing skilled technicians with experience in aluminum busbar installation to ensure compliance with industry standards and safety regulations.

Maintenance of aluminum busbar systems is equally important. Regular inspections are necessary to check for signs of wear, oxidation, or loose connections that could compromise the system’s performance. Aluminum, despite its advantages, can be susceptible to environmental factors if not properly maintained. Ensuring that the bus bar connections remain secure and oxidation-free enhances the longevity and reliability of your electrical system. Applying an appropriate protective coating can help mitigate these risks.

In conclusion, using aluminum busbars in your electrical systems can provide significant benefits, but it requires a thorough understanding of their installation and maintenance. At AP Precision Metals, we’re committed to providing top-quality aluminum bus bar solutions that meet the highest standards of performance and durability, ensuring your systems run smoothly and efficiently for years to come.

In conclusion, the utilization of aluminum busbars in electrical systems offers numerous advantages, including excellent conductivity, lightweight properties, and cost-effectiveness. These benefits combined with enhanced durability and thermal performance make aluminum busbars an optimal choice for modern electrical applications. At AP Precision Metals, we pride ourselves on delivering high-quality aluminum busbars that meet the stringent demands of today’s electrical industries. Partner with us to leverage the superior benefits of aluminum busbars for your next project.