Understanding Aluminum Bus Bars in Electrical Systems

Understanding aluminum bus bars in electrical systems is crucial for ensuring optimal performance and reliability in today’s modern electrical networks. These aluminum busbar systems have emerged as a preferred choice due to their unique combination of lightweight design and excellent electrical conductivity. Aluminum bus bars serve as a streamlined solution capable of handling substantial electrical power requirements while maintaining a cost-effective approach. The integration of aluminum bus components into electrical systems offers an innovative way to enhance efficiency in energy distribution, ultimately supporting more sustainable and effective power delivery across a range of applications.

Aluminum busbars are essential for forming the backbone of electrical systems where high current is frequently managed. Unlike traditional copper alternatives, aluminum bus bars are characterized by their affordability and ease of installation, a benefit that significantly reduces the overall costs in system setup and maintenance. By using aluminum bus solutions, engineers can achieve notable improvements in both the operational flexibility and overall efficiency of busbars in electrical applications.

Bus technology, especially the aluminum variety, facilitates seamless energy distribution, imperative in managing the power needs inherent in modern infrastructures. System designers and engineers must understand these aluminum bus components’ characteristics to fully unleash their capacity to transform electrical power management. At AP Precision Metals, we specialize in providing cutting-edge solutions with aluminum bus bars, ensuring your electrical systems are equipped with the most reliable and efficient components available today.

Advantages of Aluminum in Modern Electrical Applications

In today’s dynamic electrical landscape, aluminum emerges as an advantageous choice for modern applications, particularly in the form of busbars. One of the primary advantages of aluminum lies in its being more lightweight and less costly compared to other metals, which aligns well with industry requirements to reduce overall system stress and costs. These attributes make aluminum an ideal option for applications requiring efficient current conduction, as it enhances system efficiency while maintaining budgetary constraints. This adaptability is crucial in high-demand electrical environments where metal selection impacts performance and cost-effectiveness.

Aluminum busbars stand out as effective conductors in various systems, providing substantial benefits such as reduced energy consumption and minimized material use. By efficiently conducting electricity with reduced resistance, these busbars optimize energy distribution across electrical systems, enhancing overall performance. Furthermore, aluminum’s ability to maintain structural integrity under high current conditions ensures consistent functionality in demanding applications.

As electrical systems grow increasingly complex, leveraging the benefits of aluminum in busbar applications translates to improved system reliability and efficiency. Given these advantages, aluminum positions itself as a preferred metal in various electrical scenarios, underscoring its importance in meeting modern demands for effective current management. The advantages of aluminum in modern electrical systems are becoming increasingly recognized, making its applications and benefits a focal point of industry progression, especially where current management and conductor effectiveness are concerned.

Efficiency of Aluminum Bus in Electrical Networks

In the dynamic landscape of modern electrical systems, the use of aluminum busbars has emerged as a pivotal component in enhancing efficiency within electrical networks. Aluminum busbars are increasingly favored for their ability to carry electrical current with remarkable efficiency, making them a cost-effective choice for numerous applications. Their lightweight nature is a considerable advantage in electrical systems, offering easy installation and reduced structural requirements compared to other metals. Moreover, aluminum’s inherent resistance to corrosion further solidifies its standing in systems where reliability is paramount. As power demands escalate, the efficiency of aluminum busbars becomes even more critical, effectively channeling power through large-scale systems with minimal energy loss.

The versatility of aluminum busbar designs allows for tailored solutions in diverse settings, from industrial plants to residential complexes. These busbars excel in maintaining the stability of electrical current flow, especially in high-demand scenarios, ensuring that systems remain operational and efficient. AP Precision Metals recognizes these benefits and continuously innovates in the production of aluminum busbars, serving as a cornerstone in the optimization of modern electrical networks. By integrating aluminum into the core of electrical system design, industries can achieve significant improvements in energy consumption, leading to substantial cost savings and enhanced sustainability. Thus, the focus on the efficiency of aluminum busbars is not merely a trend but a necessary step in advancing today’s electrical infrastructures.

Comparing Aluminum Busbars with Copper Alternatives

In the realm of modern electrical systems, aluminum and copper busbars each have their distinct advantages. When comparing aluminum busbars with copper alternatives, it’s essential to weigh various factors such as conductivity, cost, and weight. Copper, renowned for its superior electrical conductivity, can indeed carry more current than aluminum. The intrinsic ability of copper to transfer electricity efficiently makes it the material of choice for applications demanding high performance, especially where space and thermal management are critical. With repeated emphasis on copper’s strengths, it’s clear why copper holds a near-universal appeal in electrical engineering.

However, aluminum busbars also present compelling benefits, notably in larger installations where weight savings translate into substantial economic advantages. Although copper carries more current, aluminum’s lightness often results in reduced infrastructure costs and simplified installation processes, especially when dealing with extensive lengths. This brings us to a crucial consideration: while copper, copper, and more copper are the norm in small or space-constrained environments, aluminum busbars shine in scenarios where large-scale implementation is crucial. Their lighter weight means less strain on supporting structures and, consequently, a reduction in material costs.

Ultimately, the decision between aluminum and copper busbars should factor in the specific requirements of the project. Whether it’s the traditional preference for copper or the practical advantages of aluminum, selecting the right material is pivotal to optimizing performance and efficiency in modern electrical systems.

Key Applications of Busbars in High Current Systems

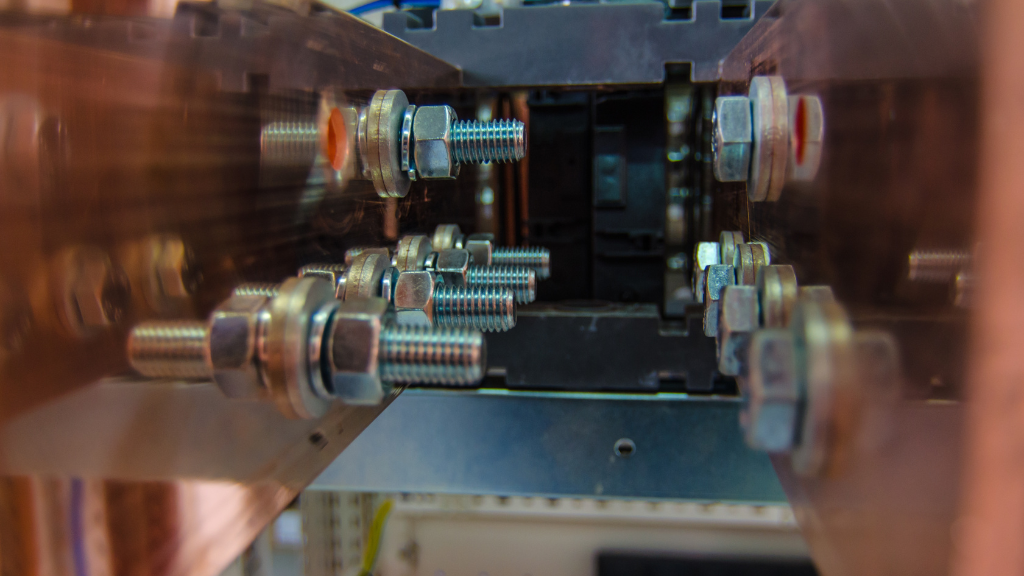

Busbars have become indispensable in modern electrical systems due to their ability to handle high current systems efficiently. Primarily, aluminum busbars are used because of their lightweight nature and excellent thermal conductivity. One of the key applications of busbars is in power distribution, where they provide a streamlined solution compared to traditional wiring methods. High current systems demand robust solutions, and aluminum busbars fit perfectly in this role by reducing electrical losses and improving system reliability. In industrial applications, these busbars are essential in managing the electrical load in large equipment and facilities. Unlike copper bus alternatives, which are heavier and more expensive, aluminum busbars offer a cost-effective yet reliable solution for high current power needs. In modern electrical applications such as data centers and renewable energy systems, busbars play a critical role in ensuring seamless power flow and reducing system downtime. By using aluminum rather than copper, electrical systems can benefit from reduced costs and increased efficiency. Within these systems, the bus is often the backbone, connecting various equipment seamlessly. The adoption of aluminum busbars in high current system applications continues to grow, driven by the need for efficient and reliable electrical solutions. This shift is aided by the versatility and adaptability of aluminum busbars in various electrical applications.

Single Equipment Solutions Using Aluminum Components

At AP Precision Metals, our expertise in crafting custom aluminum components ensures optimal performance for single equipment solutions. Single equipment installations significantly benefit from the lightweight nature and thermal efficiency of aluminum, making it an ideal choice for various applications. These installations rely heavily on precision-manufactured aluminum components, which are expertly crafted using advanced CNC machinery to meet stringent specifications. By choosing aluminum, you’re opting for a material that provides excellent conductivity while reducing overall system weight, improving both efficiency and ease of installation. Our blog discusses the versatility of aluminum in modern electrical systems and highlights the superiority of aluminum solutions in comparison to their counterparts. Components made of aluminum not only offer improved thermal management but also enhance the durability of installations across various environments. Leveraging CNC machines, we ensure each aluminum piece is tailored to meet the exact requirements of your system, guaranteeing reliability and performance. The decision to utilize aluminum in single equipment solutions translates to cost-effective, sustainable, and efficient operations. At AP Precision Metals, we prioritize delivering cutting-edge, high-quality aluminum solutions designed to optimize any electrical application. Explore our blog for more insights into how these aluminum components can drive innovation and efficiency in your projects, showcasing the pivotal role they play in contemporary settings. Choose AP Precision Metals for your next single equipment installation and experience the unparalleled benefits that aluminum can offer.

In conclusion, the utilization of aluminum busbars in modern electrical systems offers various benefits, including cost-effectiveness, lightweight design, and excellent thermal and electrical conductivity. At AP Precision Metals, we are committed to delivering high-quality bus bar systems that meet industry standards and tailored solutions for your unique needs. Experience enhanced performance and reliability by choosing our expertly crafted aluminum busbars for your next project. Contact us today at AP Precision Metals to learn how we can assist you in optimizing your electrical system’s efficiency and sustainability.