At AP Precision, we understand that when it comes to metal fabrication, precision, efficiency, and consistency are everything. Our fabrication process is designed with these priorities at the core, allowing us to deliver high-quality custom parts and assemblies for industries ranging from electronics to defense and beyond.

Whether you’re an engineer, purchasing agent, or product developer, understanding our step-by-step approach can help you see how we bring your ideas to life — with accuracy, scalability, and a sharp focus on results.

Step 1: Initial Consultation and Project Review

Every project begins with a detailed consultation. During this phase, we discuss your project requirements, part specifications, production volume, and timelines. Whether you’re coming to us with a concept drawing or fully developed CAD files, we take the time to understand the scope and ensure all technical needs are clearly defined from the outset.

Our team evaluates your design, material requirements, tolerances, and end-use environment. We’ll also help identify potential cost-saving opportunities or improvements in manufacturability. This collaborative approach ensures that every fabrication job is both technically sound and economically viable.

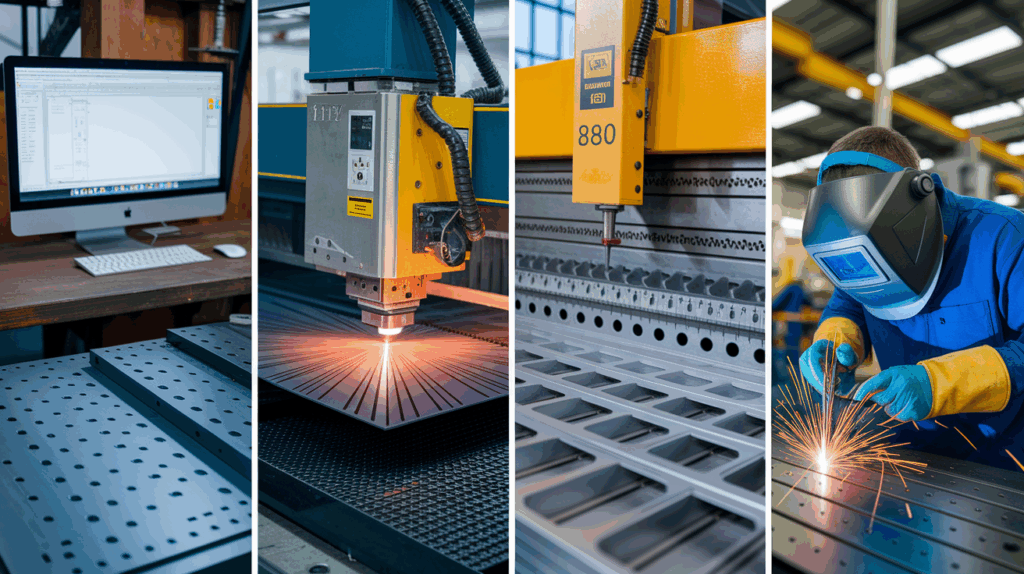

Step 2: Engineering and CAD Modeling

Once the project scope is approved, our in-house engineers work with advanced CAD software to fine-tune your design for manufacturing. We convert your files into precise, machine-ready formats and may make adjustments for tooling, fit, or material efficiency while maintaining the functional integrity of your part.

This step is critical for minimizing waste, optimizing production, and ensuring seamless integration with downstream operations like assembly or finishing.

Step 3: Material Selection and Procurement

With design specifications finalized, we source the required raw materials from trusted suppliers. AP Precision has long-standing relationships with certified vendors, allowing us to secure high-grade metals and alloys that meet both structural and aesthetic standards. Common materials include:

- Aluminum

- Stainless steel

- Carbon steel

- Copper

We ensure that all materials meet industry standards and are suitable for the intended application, whether for corrosion resistance, strength, conductivity, or weight optimization.

Step 4: Laser Cutting and CNC Machining

With raw materials on hand, the fabrication begins. For most projects, the first manufacturing step involves precision laser cutting or CNC machining, depending on the geometry and complexity of the part.

Our facility is equipped with state-of-the-art fiber laser cutters and multi-axis CNC machines that deliver high-speed, high-accuracy results. These tools allow us to create intricate shapes and tight tolerances with minimal lead time and repeatable consistency.

Step 5: Forming and Bending

Once cut or machined, flat metal parts are formed into their desired shape using press brakes and bending equipment. Our team uses CAD-generated bend programs and custom tooling setups to ensure parts meet exact design angles and radii.

This step is crucial for structural integrity and dimensional accuracy — especially in enclosures, brackets, frames, and chassis components.

Step 6: Welding and Assembly

For components that require joining, our certified welders take over. We offer MIG, TIG, and spot welding services to accommodate a range of materials and part sizes. Our skilled technicians ensure strong, clean welds with minimal heat distortion and a finish that meets both functional and cosmetic expectations.

If your project includes hardware installation or full sub-assembly, we handle that in-house as well. Fasteners, hinges, latches, and mechanical components are assembled to spec, reducing the need for secondary operations on your end.

Step 7: Finishing and Surface Treatments

Depending on your application, parts may require additional finishing. We coordinate with vetted partners to offer services such as:

- Powder coating

- Anodizing

- Plating

- Silk screening or engraving

Surface treatments improve aesthetics, corrosion resistance, and functionality. Whether your product requires an industrial finish or a consumer-grade appearance, we ensure the final result meets your standards.

Step 8: Quality Control and Inspection

Before any part leaves our facility, it goes through a stringent quality control process. Our inspection team uses precision measurement tools and inspection protocols tailored to each job. We verify dimensions, tolerances, finish, and functionality to ensure everything aligns with the approved specifications.

From first-article inspections to full lot verification, we take quality assurance seriously — because we know your production and reputation depend on it.

Step 9: Packaging and Delivery

Once approved, finished parts are carefully packaged to prevent damage during transit. We offer a variety of delivery options to meet your timeline and logistics needs — whether you’re located in Southern California or beyond. Local delivery, freight coordination, and even drop-shipping to third-party vendors are available.

Our Commitment to Excellence

At AP Precision, our process isn’t just about cutting metal — it’s about building long-term partnerships through quality, responsiveness, and results. From prototype to production, we apply the same level of attention to detail at every step, ensuring your projects move forward on time and with confidence.

Ready to get started? Contact us today to discuss your project, request a quote, or learn more about our custom fabrication capabilities.