PRECISION METAL PROCESSING

AP PRECISION: DEPENDABLY METICULOUS QUALITY,

REASONABLY PRICED

Experienced high-volume sheet and plate processing

Serving the American Southwest and Northern Mexico

The value of US-Based production at competitive rates

ABOUT OUR CUTTING PROCESS

We lead the field in cutting technology, investment, and know-how

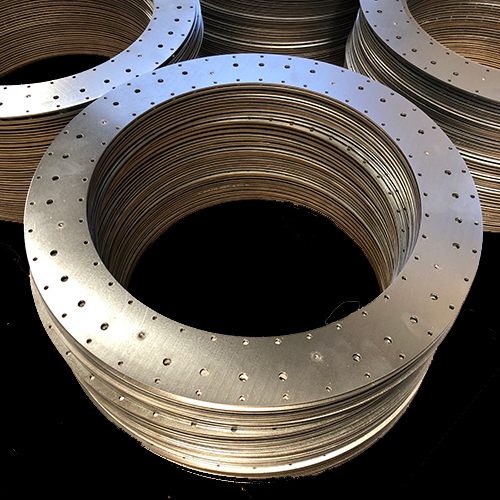

With our fiber lasers and punch presses we process over 300,000 lbs of sheet and plate steel per month. Operating at this pace in a factory that is only 40,000 square feet demands that we purchase only the best cutting machines available and maintain rigorous maintenance and operating procedures. In 2022, with the addition of our third fiber laser, our expected cutting capacity will double. We are pleased to offer this increased capability to our customers and add a few new ones as well.

OUR CUTTING EQUIPMENT

Take advantage of the most advanced machinery to deliver the highest quality products

FIBER LASERS

Fiber lasers are now both the heart and future of sheet and plate metal processing. Since 2015, AP Precision regularly invests in these machines in order to maintain productivity advantages and offer our customers the most commercially competitive pricing. The cutting precision of these lasers is better than +/-.001’’ and they have unbeatable processing speeds on metals ranging from 20GA to 1.50’’ thick. Our fiber lasers, coupled with lean manufacturing and management have enabled us to keep growing customers manufacturing here in the United States. They’re also helping new customers to reshore their work from overseas.

PUNCH PRESSES

Our punch presses provide optimal metal processing efficiency for parts with taps, bridgelances, half-shears, dimples, louvers, and countersinks. We stock a full spectrum of tooling capabilities, most of it owned ourselves, so we can offer our customers a wide assortment of tooling and capabilities, without burdening them with tooling charges.

AUTOMATED SAWS

An automated band saw provides high-accuracy bulk cutting of channel, tube and bar. Our customer product lines often require high-volume processing of these materials for frames and bases of their larger assemblies.

COUNTERSINKS & TAPPING

Many of our laser processed parts require countersinks or taps. Our state of the art machinery dedicated to these requirements ensures that we can quickly handle secondary cutting processes with minimal additional cost to the part.

EXPLORE OUR FULL RANGE OF CAPABILITIES

We’re with you every step of the production process to increase efficiency and save money

READY TO IMPROVE YOUR MANUFACTURING PROCESS?

Our team of experts will work to provide creative solutions best fit to your operations. Learn more about how AP Precision can meet your production needs and improve efficiency.