ALUMINUM BUSBAR

LEADING THE WAY IN THE ENERGY TRANSITION WITH ALUMINUM BUSBARS

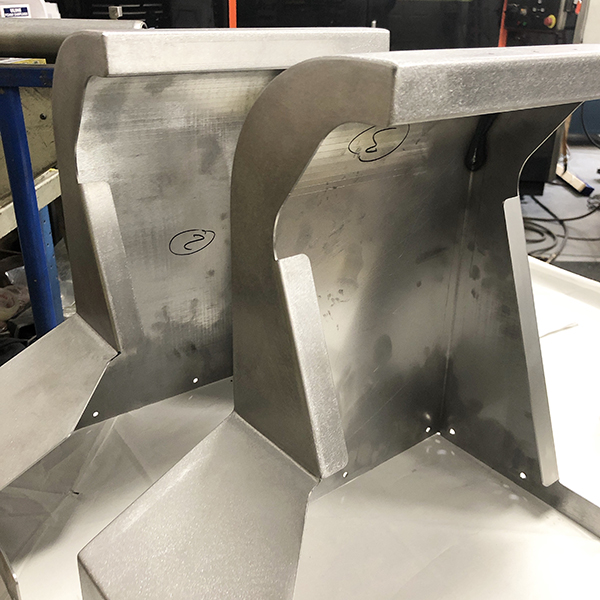

Experienced high-volume sheet and plate processing

Busbar and Cabinetry for the Western USA

High-Volume Custom Unistrut

OUR ALUMINUM BUSBAR CAPABILITIES

We lead the field in aluminum busbar manufacturing technology, investment, and know-how

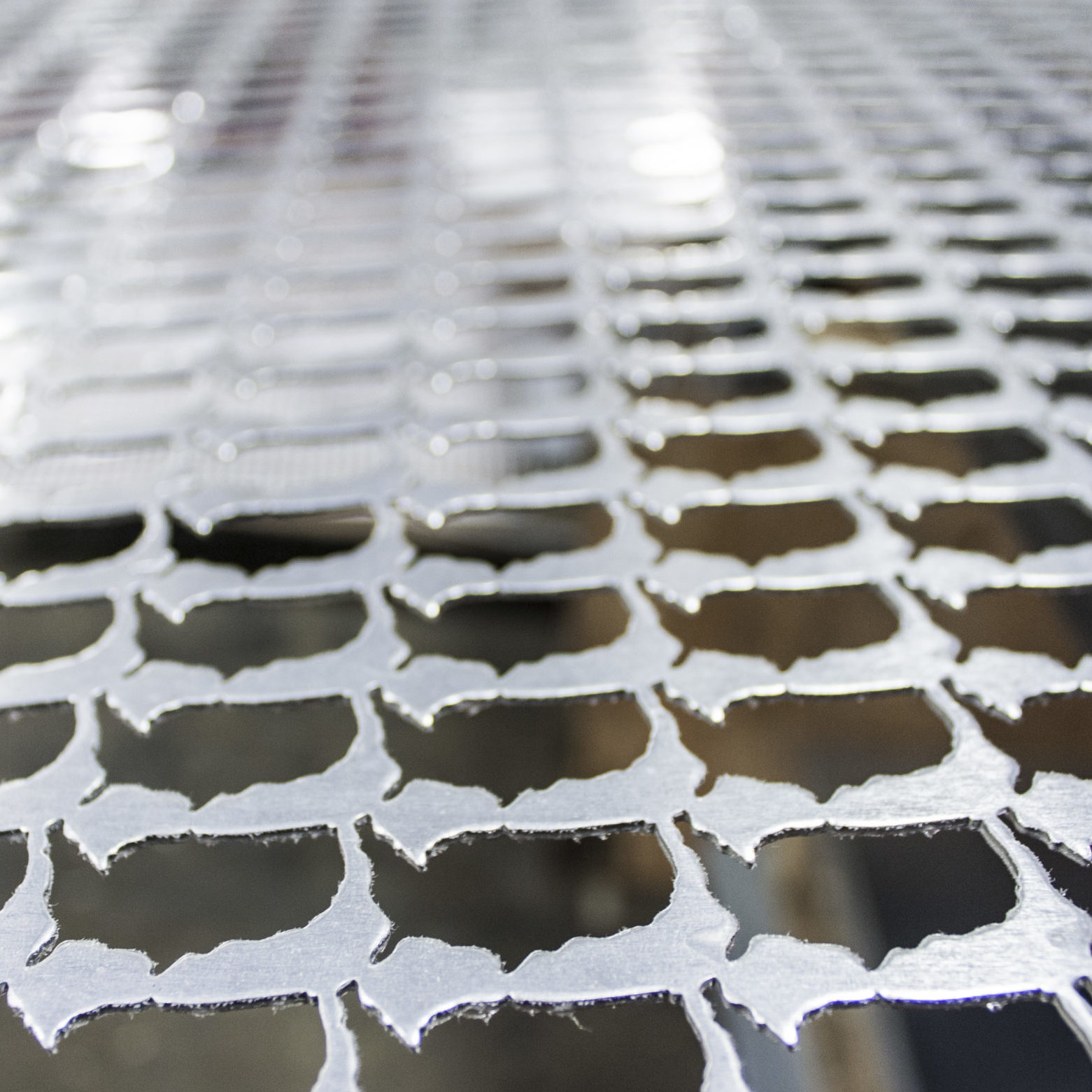

With our fiber lasers we can process over 75,000 lbs of aluminum busbar per month. Operating at this pace in a factory that is only 40,000 square feet demands that we purchase only the best cutting and forming machines available and maintain rigorous maintenance and operating procedures. In 2023 we expanded our network of plating suppliers allowing us to increase our finishing capacity. We are excited to take this leading role in the energy transition and offer this capability to our customer.

ALUMINUM BUSBARS

Take the lead in the energy transition by lowering your BOM cost.

6063-T52 Alloy

The 6063-T52 aluminum alloy is a popular choice for busbar applications due to its excellent combination of properties and benefits. This alloy is known for its high tensile strength, which ensures structural integrity and durability, making it capable of withstanding high currents and mechanical stresses encountered in electrical systems. Additionally, 6063-T52 aluminum offers superb corrosion resistance, particularly in outdoor or harsh environments, thanks to its natural oxide layer that forms on its surface, protecting it from moisture, salt, and chemical exposure. Furthermore, this alloy is ideal for cold-forming, enabling intricate designs and customized shapes to optimize current distribution and minimize voltage drops. With its lightweight nature, recyclability, formability, availability and cost-effectiveness, 6063-T52 aluminum alloy stands as an ideal material choice for busbars, offering both performance and sustainability in electrical applications.

6063-T52 VS 6101

AP Precision has opted to lean on 6063-T52 because of its significantly superior availability, which has allowed us to expand the range of design and engineering options available to our customers, and achieve the best pricing, particularly on extra-large busbars. 6063-T52 aluminum alloy offers ideal formability, superior availability and exceptional corrosion resistance, making it suitable for busbar applications where moderate strength and complex forms are needed. In contrast, 6101 aluminum alloy provides superior mechanical strength, durability, and a slightly higher AICS conductivity rating, making it preferable for busbars subjected to heavier loads or higher mechanical stresses. Ultimately, the choice between the two alloys depends on the specific requirements of the application, balancing factors such as conductivity, mechanical strength, formability, cost and bar design.

ALUMINUM vs COPPER BUSBAR

Aluminum busbars offer several advantages over copper counterparts, making them an attractive choice in various electrical applications. The primary benefit is their lower cost. Aluminum is more abundant and less expensive to produce compared to copper, resulting in significant cost savings, especially in large-scale electrical installations where extensive lengths of busbars are required. Additionally, aluminum's lighter weight simplifies handling and installation, reducing labor costs and strain on supporting structures. Despite having slightly lower conductivity than copper, aluminum busbars can compensate by utilizing larger cross-sectional areas, ensuring efficient current transmission without sacrificing performance. Moreover, aluminum's excellent corrosion resistance and recyclability contribute to its durability and environmental sustainability, making it a compelling alternative to copper in electrical systems. Overall, the benefits of aluminum, including cost-effectiveness, lightweight design, adequate conductivity, durability, and recyclability, make it a preferred choice for busbars in various applications.

EXPLORE OUR FULL RANGE OF CAPABILITIES

We’re with you every step of the production process to increase efficiency and save money.

READY TO IMPROVE YOUR MANUFACTURING PROCESS WITH CUSTOM BUSBARS?

Our team of experts will work to provide creative solutions best fit to your operations. Learn more about how AP Precision can meet your production needs and improve efficiency.

FREQUENTLY ASKED QUESTIONS

We lead the field in aluminum busbar know-how

Aluminum busbars are flat bars used for electrical conductivity in switchgear, battery applications, and other electrical installations. They offer a lightweight alternative to copper busbars while maintaining excellent conductivity.

Aluminum busbars provide high electrical conductivity at a lower weight than copper. While copper busbars have higher thermal and electrical performance, aluminum is often chosen for its corrosion resistance, ease of fabrication, and cost-effectiveness.

Aluminum busbars are lightweight, corrosion-resistant, and cost-effective compared to copper busbars. They are commonly used in switchgear, electrical busbars, and battery applications due to their efficient heat dissipation.

Yes, aluminum busbars provide excellent electrical conductivity for various applications, including power distribution, switchgear, and industrial electrical bus systems. They are often chosen for their balance of weight, cost, and performance.

Yes, aluminum busbars have natural corrosion resistance due to their oxide layer, making them ideal for electrical installations where environmental factors impact metal longevity. Proper material selection ensures durability in various applications.