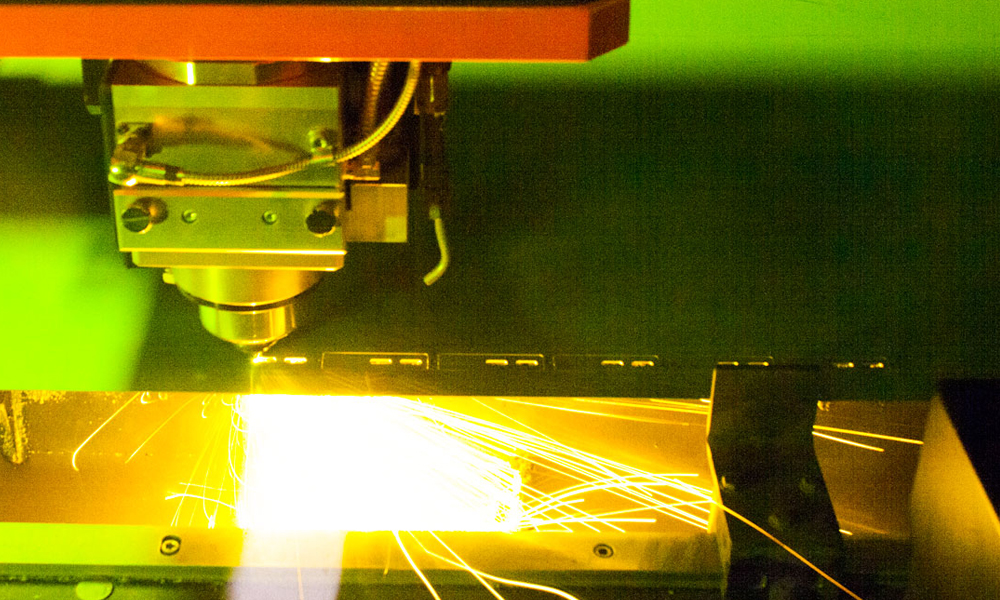

A frequent inquiry when producing metal parts is “What would be the expense of laser cutting?” To answer this, it’s essential to comprehend the various elements that affect the overall cost of utilizing laser cutters. To help you make the right decisions for your production needs, this blog post will discuss various factors that influence laser cutting costs.

We will discuss the different types of lasers available for cutting purposes – high-power fiber lasers and CO2 lasers – and how their capabilities impact costs. Additionally, we’ll examine how material strength affects cutting time and how specific production requirements can alter overall expenses.

Furthermore, our discussion will compare in-house laser cutting operations versus outsourcing services by analyzing advantages and disadvantages associated with each approach. We will also guide you through calculating hourly rates for laser cutting services based on equipment costs, labor rates, and overhead expenses.

Lastly, we’ll introduce popular laser cutter options such as Monport’s LightBurn, Glowforge Pro, and FLUX BeamBox Pro to help you choose the right machine for your projects. By understanding all these aspects related to “How much should laser cutting cost?”, you can optimize your manufacturing processes while maintaining quality standards at competitive prices.

Table of Contents:

- Factors Affecting Laser Cutting Costs

- Type of Laser: High-Power Fiber vs CO2

- Material Strength Affecting Cutting Time

- Production Requirements Impacting Overall Costs

- In-house Laser Cutting Operations

- Outsourcing Laser Cutting Services

- Calculating Hourly Rates for Laser Cutting Services

- Popular Laser Cutter Options

- FAQs in Relation to How Much Should Laser Cutting Cost?

- Conclusion

Factors Affecting Laser Cutting Costs

Determining how much laser cutting services should cost depends on several factors such as the type of laser used, material strength, and production requirements. This section will delve into the various factors influencing laser cutting expenses, providing a better comprehension of the associated costs.

Type of Laser: High-Power Fiber vs CO2

The choice between high-power fiber lasers and CO2 lasers plays a significant role in determining the overall cost of your project. Fiber lasers are best for cutting steel due to their efficiency and speed while CO2 lasers work well with acrylic materials. The type of laser cutter depends on the specific needs of your project; however, it is essential to note that each option comes with its own set of advantages and disadvantages when considering both performance and price.

Material Strength Affecting Cutting Time

The strength of the material being cut also impacts the total cost since stronger materials may require more time under the laser cutter. This increased processing time can lead to higher labor costs as well as additional expenses related to shipping methods if longer production times affect delivery schedules.

Production Requirements Impacting Overall Costs

- Laser Power: Higher-powered machines typically come at a higher price but can produce faster results, potentially offsetting some initial investment costs through improved productivity.

- Precision: More precise cuts often require more advanced laser cutting machines, which can increase the overall cost of your project.

- Volume: Large-scale production runs may necessitate industrial-grade machine investments or outsourcing to specialized service providers, both of which can impact costs significantly.

In summary, understanding these factors and how they affect the average cost of laser cutting services is crucial for companies looking to manufacture metal components. By considering aspects such as the type of laser cutter used, material strength, and specific production requirements, businesses can make informed decisions about their investment in laser cutting technology and ensure a successful outcome for their projects.

Weighing the multiple elements that could influence laser cutting expenditures is essential when deciding whether to buy an in-house machine. Before committing to an in-house laser cutter, one should weigh the pros and cons of such a purchase.

Key Takeaway: Determining the cost of laser cutting services depends on factors such as the type of laser used, material strength, and production requirements. The choice between high-power fiber lasers and CO2 lasers affects costs significantly, while stronger materials may require more time under the laser cutter leading to higher labor costs. Production requirements such as laser power, precision, and volume also impact overall costs for businesses investing in this technology.

In-house Laser Cutting Operations

Investing in a high-quality precision laser cutter can be daunting due to its initial expense but offers numerous advantages like complete control over production rate and quality control. However, owning a personal machine comes with disadvantages such as requiring ample space for housing it along with time investment needed to learn how to operate it efficiently.

Advantages of Owning a Personal Machine

- Control: Having your own laser cutting machine allows you full control over the entire process, from design adjustments to final product output.

- Quality Assurance: In-house operations ensure that you maintain strict quality standards without relying on external providers.

- Economies of Scale: As your business grows and production volume increases, owning an industrial-grade machine could result in cost savings through economies of scale.

Disadvantages Including Space Requirement and Learning Curve

- Maintenance Costs: Apart from the initial purchase price, maintaining a laser cutter depends on factors such as replacement parts or service fees which can add up over time. Additionally, unexpected breakdowns may lead to downtime affecting overall productivity levels within organizations themselves.

- Floor Space Requirements: Owning a large piece of equipment like a laser cutting machine requires ample space to house it safely and efficiently. This can be a challenge for businesses with limited floor area or where the cost of real estate is high.

- Learning Curve: Operating a laser cutter requires specialized knowledge and training. This may involve investing time and resources in learning how to use the machine effectively, as well as ongoing training for staff members.

In-house laser cutting operations can be beneficial for businesses that require precise cuts on various materials like metal, acrylics, or wood. Before committing, it’s essential to evaluate the pros and cons of possessing a laser cutter. Some popular options for laser cutters include fiber lasers known for their efficiency in cutting steel or CO2 lasers which work well with acrylic materials. By understanding your specific production requirements and available resources, you can make an informed decision about whether investing in an industrial-grade machine is right for your business needs.

In-house Laser Cutting Operations can provide a cost effective solution for companies looking to manufacture metal components, however outsourcing laser cutting services may be beneficial in certain situations. Outsourcing operations can offer flexibility and convenience that an in-house machine cannot provide.

Key Takeaway: Investing in a high-quality precision laser cutter can provide control over production rate and quality assurance, but requires ample space for housing it along with time investment needed to learn how to operate it efficiently. In-house operations ensure strict quality standards without relying on external providers, while maintenance costs and floor space requirements should be considered before making any decisions.

Outsourcing Laser Cutting Services

Outsourcing your operations could help avoid issues related to in-house machinery ownership without compromising quality or turnaround times significantly. Benefits include not having to hire laborers or deal with equipment failures/replacements while also eliminating concerns about scrap metal storage/recycling management – all aspects that contribute towards lowering operational costs associated specifically with running machines internally within organizations themselves.

Benefits of Outsourcing Operations

- Reduced Labor Costs: By outsourcing laser cutting services, companies can save on the expenses involved in hiring and training skilled workers for operating laser cutters.

- No Equipment Maintenance: Companies don’t have to worry about maintaining their own laser cutting machines, as this responsibility falls on the service provider. This reduces downtime due to machine breakdowns and ensures consistent production output.

- Better Resource Allocation: Outsourcing allows businesses to focus on core competencies such as product design, marketing, and customer service instead of managing a complex manufacturing process like laser cutting.

- Eco-friendly Practices: Professional laser cutting service providers often have better waste management systems in place for handling scrap materials generated during the process, reducing environmental impact.

Drawbacks Including Slower Turnaround Times

In some cases, outsourcing may lead to slower turnaround times compared to in-house operations. Factors affecting this include communication delays between parties and shipping timeframes when sending raw materials/components back-and-forth between locations. However, by partnering with a reliable contract manufacturer like AP Precision that specializes in providing high-quality precision cuts using advanced fiber lasers and CO2 laser systems, businesses can minimize these drawbacks.

When considering outsourcing your laser cutting needs, it’s essential to research and compare different service providers. When selecting a partner for outsourcing laser cutting services, it is important to consider their track record of delivering satisfactory results in an appropriate timeframe. Some factors to consider when selecting an outsourced partner include their experience working with similar materials or industries, availability of advanced laser cutting machines, and positive customer reviews.

In conclusion, outsourcing laser cutting services offers numerous benefits such as reduced labor costs, better resource allocation, and eco-friendly practices while minimizing potential drawbacks like slower turnaround times by partnering with a reliable contract manufacturer like AP Precision that specializes in providing high-quality precision cuts using advanced fiber lasers and CO2 laser systems.

Outsourcing laser cutting may be a viable cost-cutting measure, but it is essential to factor in the different variables that can affect pricing. Calculating hourly rates for these services takes into account equipment costs, labor rates, and overhead expenses in order to determine an accurate cost estimate.

Key Takeaway: Outsourcing laser cutting services can help companies save on labor and equipment costs while focusing on core competencies. However, slower turnaround times may be a drawback, so it’s important to research and compare different service providers before partnering with one like AP Precision that specializes in high-quality precision cuts using advanced fiber lasers and CO2 laser systems.

Calculating Hourly Rates for Laser Cutting Services

Determining the appropriate pricing for laser cutting services is crucial to ensure profitability while offering competitive rates. Calculating an hourly rate for laser cutting services necessitates taking into account such factors as equipment costs, labor rates, and overhead expenses. This section will discuss these elements in detail and provide guidance on how to establish a fair price structure.

Equipment Costs Influencing Hourly Rates

The cost of laser cutting machines varies significantly depending on their capabilities and features. The price tag for top-of-the-line laser cutting equipment can range from tens of thousands to hundreds of thousands. When calculating your hourly rate, consider the initial investment made in purchasing or leasing the machine along with any maintenance costs that may arise over time.

Labor Rates Affecting Pricing

In addition to equipment costs, labor rates play a significant role in determining your laser cutting service’s pricing structure. The skill level required for operating laser cutters depends on the type of machine used, such as fiber lasers or CO2 lasers. Therefore, it is essential to factor in employee wages when setting prices. Additionally, consider any training programs needed for staff members to operate these complex machines efficiently.

Overhead Expenses to Consider

- Rent: If you are running your laser cutter business out of rented space or if you have taken out loans against property ownerships – remember that rent payments (or mortgage installments) must be factored into overall operational expenditures when calculating hourly rates.

- Utilities: Laser cutting machines consume a significant amount of energy, so it is essential to account for utility costs such as electricity and water when determining your pricing structure.

- Insurance: Insurance premiums are another overhead expense that should be considered. Business owners must ensure their laser cutters and other equipment are adequately insured against potential damage or theft.

In conclusion, setting an appropriate hourly rate for laser cutting services involves considering various factors like equipment costs, labor rates, and overhead expenses. By taking these elements into account, businesses can establish competitive prices while ensuring profitability in the long run. To further enhance your knowledge on this topic, explore our comprehensive guide on laser cutting costs.

By taking into account the cost of equipment, labor rates and overhead expenses associated with laser cutting services, companies can accurately calculate their hourly rate. Popular laser cutter options such as Monport’s LightBurn, Glowforge Pro and FLUX BeamBox Pro offer varying levels of quality to meet different project needs.

Key Takeaway: To establish a fair price structure for laser cutting services, businesses should calculate an hourly rate based on factors such as equipment costs, labor rates, and overhead expenses. The cost of the machine and any maintenance costs must be considered along with employee wages and training programs needed to operate these complex machines efficiently. Overhead expenses like rent payments or mortgage installments, utility costs such as electricity and water, and insurance premiums are also significant factors that should be taken into account when determining pricing structures.

Popular Laser Cutter Options

Deciding on the correct laser cutter for your enterprise is imperative to guarantee proficiency, quality, and value. Various laser cutters are available in the market to suit different requirements and budgets. In this section, we will discuss some popular laser cutters such as Glowforge Pro and FLUX BeamBox Pro.

Monport’s LightBurn as an Affordable Option

If you’re looking for a budget-friendly option without compromising on quality, Monport’s LightBurn could be an excellent choice. Priced at around $550, it offers precise cuts with its powerful CO2 laser system. This machine is suitable for small businesses or hobbyists who need a reliable yet affordable solution for their cutting needs.

Glowforge Pro for Higher-End Projects

The Glowforge Pro is another popular option among professionals due to its advanced features and capabilities. With a price tag of approximately $7,000, it boasts a high-powered 45W CO2 laser that can efficiently handle intricate designs on various materials like wood, acrylics, and leather, making it ideal for more demanding projects where precision matters most.

FLUX BeamBox Pro with Versatile Cutting Abilities

The FLUX BeamBox Pro stands out from other machines because of its versatility in handling multiple materials thanks to its 50W CO2 lasers which can easily cut through fabrics, paper, wood, plastics, and even metals. Its user-friendly interface makes operation simple even if you’re new to using industrial-grade machines like these. Priced at around $4,000, it offers a good balance between affordability and performance.

When selecting the right laser cutter for your business needs, consider factors such as material compatibility, cutting speed, precision requirements, and budget constraints. It’s also essential to research each machine thoroughly by reading reviews from users who have firsthand experience with them. This will give you valuable insights into their strengths and weaknesses so that you can make an informed decision when investing in a laser cutting machine.

Key Takeaway: Choosing the right laser cutter is crucial for your business’s efficiency, quality, and cost-effectiveness. Popular options include Glowforge Pro and FLUX BeamBox Pro, but Monport’s LightBurn offers a budget-friendly option without compromising on quality. Consider factors such as material compatibility, cutting speed, precision requirements, and budget constraints when selecting the right machine for your needs.

FAQs in Relation to How Much Should Laser Cutting Cost?

What is the Average Cost of a Laser Cutter?

The average cost of a laser cutter varies depending on factors such as type, power, and size. Generally, prices range from $1,000 for entry-level models to over $20,000 for industrial-grade machines. For example, the Glowforge Pro costs around $5,995 while the FLUX BeamBox Pro is priced at approximately $4,499.

How is Laser Cutting Cost Calculated?

Laser cutting costs are typically calculated based on material type and thickness, machine time (including setup), labor expenses, and overheads like electricity usage. Some companies may also factor in design complexity or additional services like finishing or assembly when determining pricing.

How Do You Price a Laser Project?

To price a laser project accurately:

- Determine the hourly rate by considering machine operating costs and labor expenses.

- Analyze material requirements including type and thickness.

- Add any extra charges for complex designs or additional services like finishing or assembly.

- Multiply the hourly rate by estimated production time to get total project cost.

Why is Laser Cutting So Expensive?

Laser cutting can be expensive due to high initial equipment investments required along with ongoing operational costs such as maintenance fees and energy consumption. Additionally, skilled operators are needed which further increases labor expenses. Complex projects requiring intricate designs may also contribute to higher overall pricing.

Conclusion

After reviewing the different factors that impact laser cutting costs, it is clear that there are many variables to consider. The type of laser used, material strength, and whether to invest in personal equipment or outsource services can all affect pricing structures.

To determine appropriate pricing for your project, it is important to calculate hourly rates based on various factors and balance volume ordered with actual output. Additionally, popular laser cutter options such as Monport’s LightBurn, Glowforge Pro, and FLUX BeamBox Pro have varying costs depending on their capabilities.

If you’re looking for high-quality metal components at a fair price point, turn to AP Precision Metals Inc. Our skilled staff utilize the latest technology and top-notch components to craft custom pieces tailored precisely for your requirements. Contact us today to learn more!