THE HISTORY OF AP PRECISION METALS

PROUDLY SERVING OUR CUSTOMERS WITH RELIABLE METAL FABRICATION SINCE 2000

OUR STORY

A proven history of strategic partnerships and customer success

Over the past twenty-plus years we’ve helped clients achieve their desired outcomes through a wide range of business climates and commercial fluctuations. Our comprehensive industry knowledge and manufacturing expertise have guided us and our partnerships, time and time again, toward ever-greater growth and success.

AP Precision was founded as a supplier to its former parent company, Arc Products, a welding automation manufacturer now owned by Lincoln Electric. Though we’ve been independent for over a decade, fundamental to our company’s DNA is the knowledge that our success is our customer’s success.

In the past decade, we’ve had the pleasure of being the primary metal part supplier for a number of companies that have grown and sold, some of them many times over. Keeping pace with customers whose annual revenues have gone from $10 million to $100 million or from $100 million to $200 million, has required close collaboration, ongoing capital investments, and an eagerness to adapt our manufacturing and quality systems to meet their evolving requirements. We think you’ll also find it worthwhile to test our mettle and see how AP Precision can be the ideal metal fabrication solution for your business.

1986

PARTNERSHIP

Lane Litke and Victor Miller, new friends with young families, moved to San Diego and established Arc Products. Their company focused on arc welder repair in the early days of advanced PCB controlled welding equipment.

1990

EXPERTISE

Arc Products was designated as the global repair center for Powcon, Cyclomatic, Jetline, and the national distributor of ESAB Orbital TIG, with a focus on servicing the power industry.

1999

OEM DESIGN & ENGINEERING

Arc Products developed a proprietary line of hard automation welding machinery. This required a factory capable of PCB control manufacturing, advanced machining, electronic and mechanical assembly, as well as design engineering. The product line found an international customer base through close cooperation with Lincoln Electric and Miller ITW.

2000

AP PRECISION METALS IS FOUNDED

Arc Products developed a proprietary line of hard automation welding machinery. This required a factory capable of PCB control manufacturing, advanced machining, electronic and mechanical assembly, as well as design engineering. The product line found an international customer base through close cooperation with Lincoln Electric and Miller ITW.

2001

THE SAN DIEGO MARKET

AP Precision opened its manufacturing capabilities to other small businesses in San Diego in need of low-volume, high-precision metal components and enclosures. Possessing a keen understanding of customer needs and a wide range of manufacturing equipment, AP Precision quickly established its value and grew its customer base.

2010

A NEW VISION

In 2010 Arc Products was acquired by Lincoln Electric and shifted management of AP Precision Metals to two key employees; Dustin Campbell and Joshua Miller. Under their leadership, AP Precision expanded to 20 employees, 14,000 sq. ft. and shifted its focus toward mid-sized businesses across Southern California.

2016

ADAPTATION

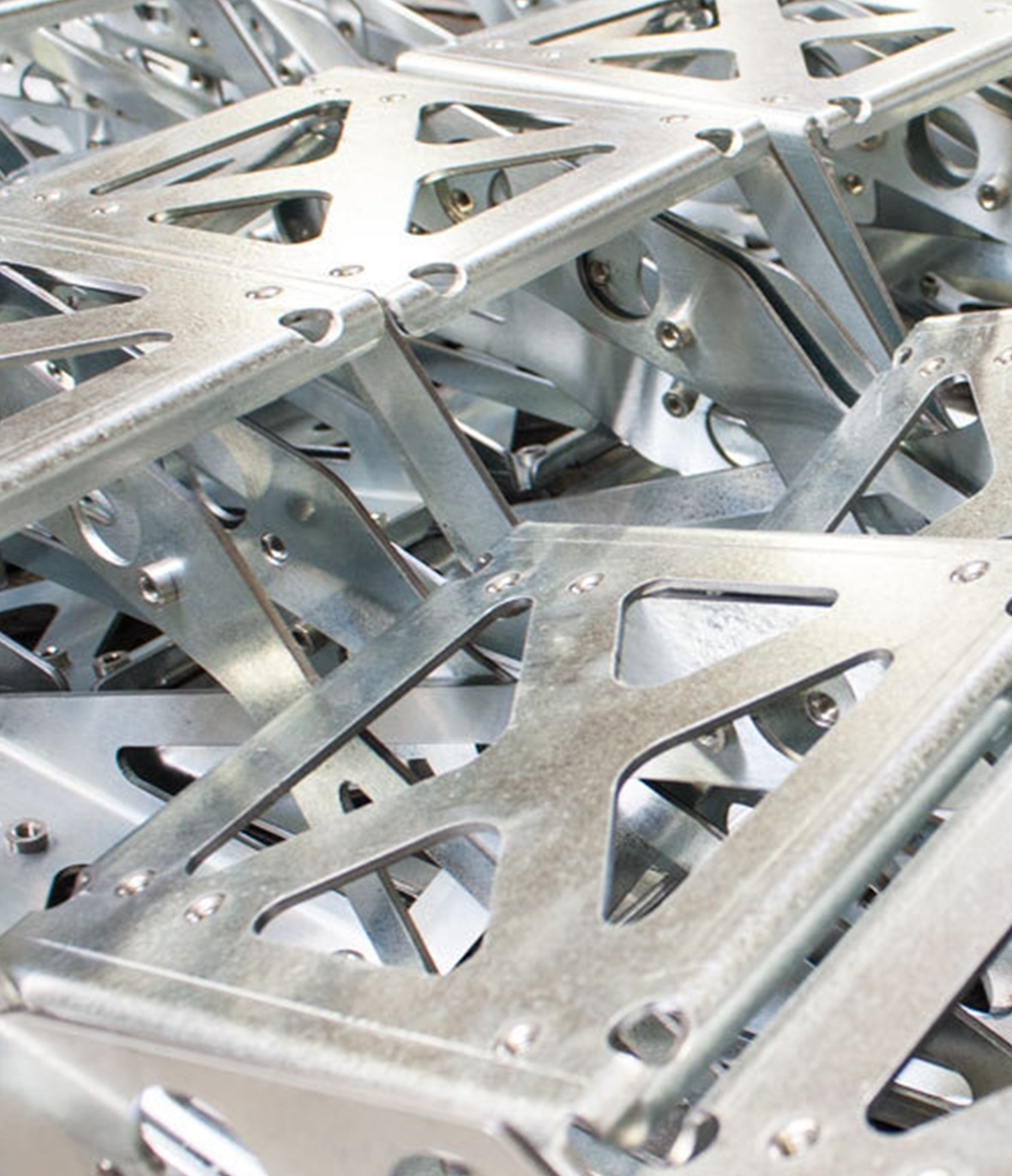

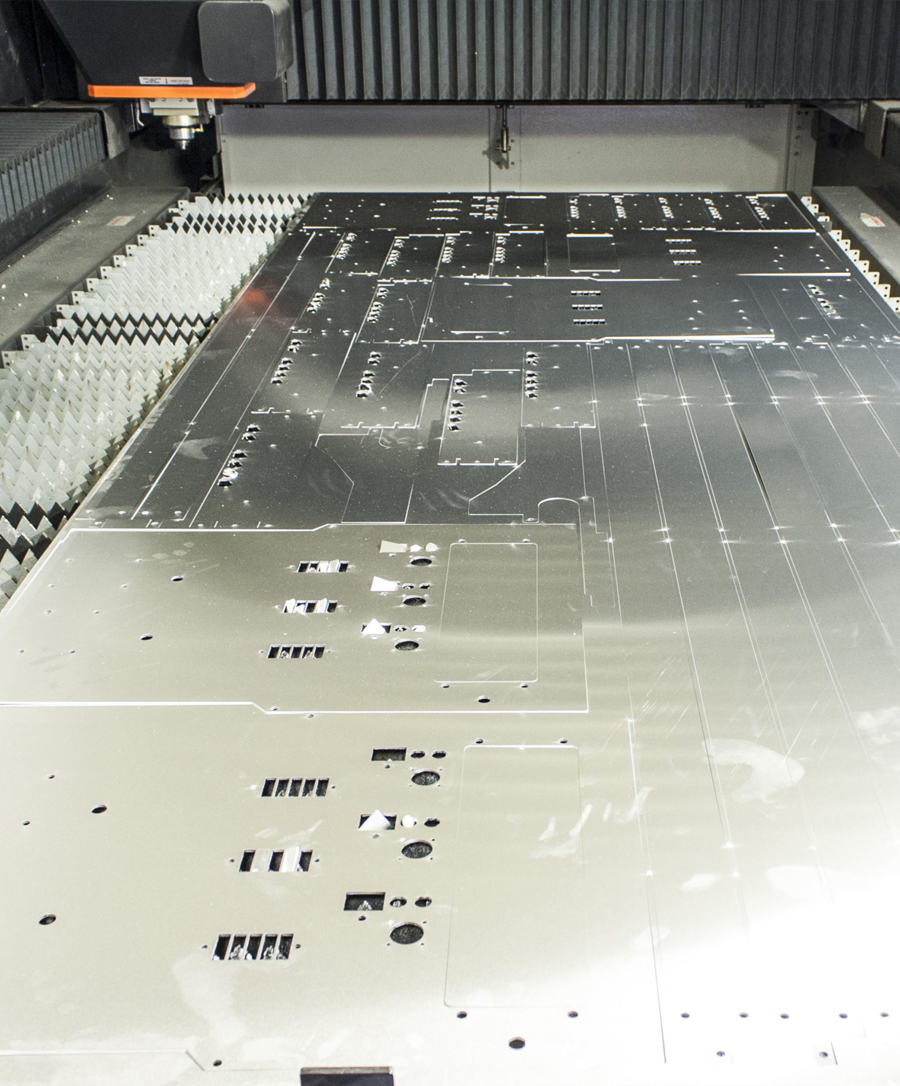

AP Precision was quick to adapt to the advent of fiber lasers, first purchasing a 4KW Mazak Fiber Laser. This machine greatly increased productivity and customer flexibility. Realizing the power of technology leaps, the company incorporated extensive manufacturing technology research into its investment planning.

2019

EXPERIENCE

AP Precision shifted its focus from in-house training to hiring experienced tradespeople and middle managers, taking on a great group of highly knowledgeable professionals. These team members brought decades of industry leadership and expertise, greatly increasing AP Precision’s manufacturing knowledge, capacity, quality standards, and work environment.

2021

PURCHASING & QUALITY

AP Precision established itself as a key, high-volume supplier for several OEMs that are publicly traded on NASDAQ. With this volume of growth, AP Precision reworked its supplier network to reduce costs. Partnering with CMTC, LSSI, and key customers, AP Precision’s entire employee base underwent LEAN training. A Quality Management team was brought on and implementation of ISO 9001:2015 began.

2022

A SECOND EXPANSION

Having added over $3,000,000 in manufacturing equipment over the previous four years, AP Precision expanded its factory to 35,000 sq. ft., under a single roof, alongside a 10,000 sq. ft. outdoor space. The new floorplan accommodates automation cells and product-specific workflows.

THE FUTURE

A NEW ERA: DOMESTIC MANUFACTURING

AP Precision’s growth and investment timed well with a global supply chain crisis. Staking its future on the potential of automation to bring significant levels of manufacturing back to the United States, AP Precision has been approached by a broad range of American OEM’s looking to reshore their metal fabrication.