Aluminum Busbar Grades and Specifications: Electrical Grade Aluminum Busbar, Aluminum Busbars Specification

Welcome to AP Precision Metals’ comprehensive guide on aluminum busbar grades and specifications. Delve into the intricacies of electrical grade aluminum busbars, including their unique properties and industry standards. Their objective is to provide you with detailed insights that ensure optimal selection and application in your electrical systems, enhancing performance and reliability. Explore the key specifications and benefits of aluminum busbars and make informed decisions for your projects.

Introduction of Chalco Conductive Aluminum Busbar

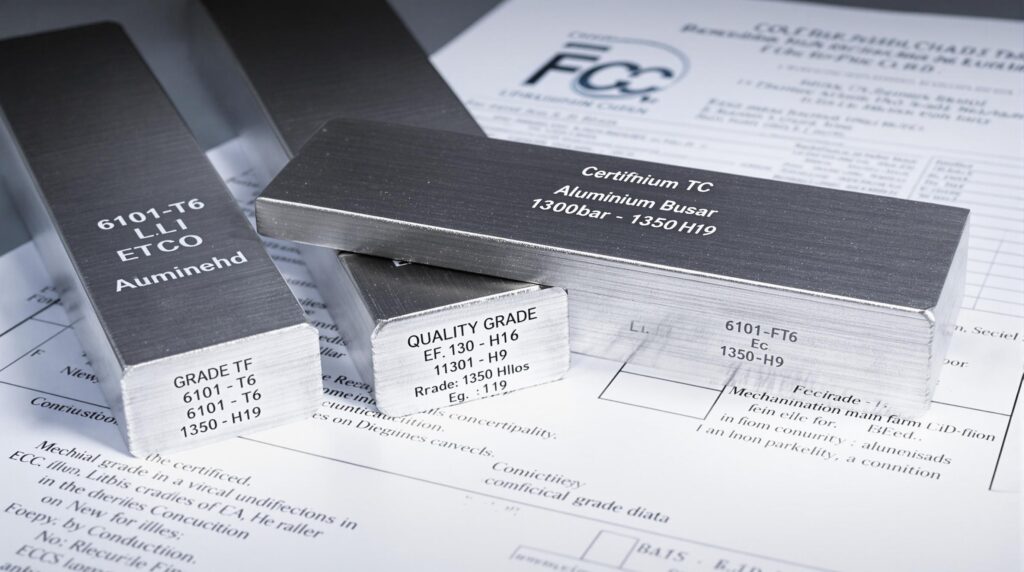

AP Precision Metals takes pride in offering high-quality aluminum bus bars that meet various industrial and electrical specifications. Aluminum busbars are crafted from top-grade aluminum alloys, ensuring excellent electrical conductivity and robust performance. Chalco Aluminum’s conductive aluminum busbar is an authorized product, recognized globally for its outstanding quality and reliability, particularly in electrical applications.

Aluminum busbars, also known as aluminum busbars, are essential components in electrical systems due to their high electrical conductivity and lightweight nature. The electrical-grade aluminum used in the aluminum busbars makes them ideal for a range of applications, from power distribution to electrical switchgear. Electrical-grade aluminum busbars are specifically designed to handle high ampacity and maintain performance under demanding conditions.

Choosing the right aluminum busbar involves understanding the specific aluminum alloys used. The aluminum bus bars come in a variety of alloys to suit different requirements. Each aluminum busbar is crafted with precision to ensure optimal performance and durability. The flexibility of aluminum as a material allows for custom specifications, enabling them to meet unique customer demands with precision-engineered solutions.

Electrical grade aluminum busbars are vital in systems where conductivity and weight are crucial factors. These aluminum busbars are effective in conducting electrical currents and offer a lightweight alternative to copper, making them easier to handle and install. The variety of aluminum busbars offered is just one of the reasons Chalco Aluminum is a trusted name in the industry.

As part of AP Precision Metals’ commitment to quality, bus bars undergo rigorous testing to meet stringent industry standards. This ensures that each aluminum bus bar produced is of the highest quality and capable of meeting the demanding needs of electrical systems. When you choose Chalco Aluminum’s conductive aluminum busbars, you’re selecting a product that stands up to the rigors of industrial use while providing superior electrical performance.

In conclusion, the introduction of Chalco Aluminum conductive aluminum busbar at AP Precision Metals signifies the dedication to delivering premium, high-performance electrical solutions. These bus bars are designed to meet stringent specifications, ensuring they provide reliable and efficient performance in various electrical applications. If you’re in need of an authorized product that guarantees exceptional quality and performance, look no further than Chalco Aluminum’s conductive aluminum busbars.

Production Capacity of Chalco Aluminum Electrical Busbar

AP Precision Metals understands the importance of high-quality aluminum busbars in electrical applications. Chalco Aluminum stands out in the industry with its impeccable production capacity for electrical-grade aluminum busbars. Leveraging advanced technology and rigorous quality control, Chalco Aluminum ensures that each busbar meets stringent industry standards. Their production lines can manufacture various bus bar types, including flat and hot-rolled options, to suit various electrical needs.

The flat bus bar produced by Chalco Aluminum is known for its excellent conductivity and durability, making it ideal for high-stress electrical environments. These flat bars are produced through state-of-the-art hot rolling processes that enhance the metal’s strength and thermal stability. The electrical grade aluminum used in these busbars is meticulously processed to ensure minimal resistance, contributing to efficient power distribution.

Chalco Aluminum production capacity extends to a wide array of bar sizes, catering to different specifications required by various industries. Whether it’s a small, compact bus bar for residential applications or a larger, more robust option for commercial or industrial use, Chalco Aluminum can deliver. Their commitment to precision and quality is evident in each bus bar produced, ensuring reliable performance and longevity.

Furthermore, their production facilities are equipped with cutting-edge machinery for efficient and consistent production of high-grade aluminum busbars. The use of advanced technology and innovative techniques in the manufacturing process ensures that each bar is uniform in quality and meets the exact specifications of electrical-grade aluminum standards. By maintaining a focus on quality and innovation, Chalco Aluminum continues to lead the market in producing superior bus bars.

In summary, Chalco Aluminum production capacity for electrical-grade aluminum busbars is unmatched in the industry. Their ability to manufacture a diverse range of bus bar options, including flat and hot-rolled varieties, ensures they can meet a wide range of electrical specifications. With a steadfast commitment to quality, every bar produced by Chalco Aluminum is designed to offer exceptional performance and reliability.

Ampacity Chart of Copper and Aluminum Busbars

When selecting the right material for busbars in electrical applications, understanding the ampacity chart for copper and aluminum busbars is crucial. AP Precision Metals recognizes the inherent strengths of copper and aluminum in distributing electrical power. The ampacity chart outlines the current carrying capacity of copper and aluminum busbars across various dimensions and specifications. With a detailed comparison between the two materials, professionals can make informed decisions based on ampacity, strength, and economic considerations.

For those working within stringent standards, determining the appropriate grade aluminum busbar is essential. Aluminum busbars are available in different grades that meet various ASTM requirements, ensuring the material’s integrity and reliability. These aluminum grade busbars are an excellent choice for applications like battery connectors, where weight and conductivity matter.

Our ampacity chart outlines the current carrying capacity of copper and aluminum busbars across various dimensions (mm) and specifications. With a detailed comparison between the two materials, professionals can make informed decisions based on ampacity, strength, and economic considerations. Whether dealing with a copper busbar that necessitates robust performance or an aluminum busbar that offers a lightweight solution, having precise ampacity information is invaluable.

Furthermore, while copper is known for its superior ampacity and mechanical strength, aluminum offers a significant advantage in terms of weight and cost. Both materials must comply with relevant standards, ensuring they meet the necessary requirements for safe and efficient electrical conduction. Consequently, selecting copper and aluminum busbars often hinges on specific application requirements and economic factors.

AP Precision Metals provides an extensive range of copper and aluminum busbars tailored to meet diverse industrial needs. This team ensures that each busbar meets rigorous ASTM standards, offering reliability and performance you can trust. By consulting the ampacity chart, you’ll find the necessary data to choose the appropriate material—copper or grade aluminum busbar—suited for your specific project requirements.

Understanding the ampacity chart of copper and aluminum busbars offers a foundation for optimizing electrical distribution solutions. AP Precision Metals invite industry professionals to utilize the comprehensive resources and expertise to make well-informed decisions on material selection for busbars.

Conductive Aluminum Busbar Size Reference Table

In the Conductive Aluminum Busbar Size Reference Table, you’ll find a comprehensive guide to the various aluminum busbar grades and specifications designed for high efficiency in electrical transmission. Understanding the distinctions between different aluminum busbars is critical for optimizing your electrical systems. Each aluminum alloy used in busbars offers unique advantages, tailored to meet specific performance needs. For instance, when comparing aluminum and copper busbar options, aluminum often provides a lightweight yet highly conductive alternative, facilitating easier installation and handling without sacrificing conductivity.

Our reference table covers a range of aluminum busbar sizes available to suit various electrical infrastructure needs. The detailed breakdown ensures that you can pinpoint the exact aluminum grade and flat bar dimensions that align with your project requirements. Standard sizes are provided in mm, offering precise measurements for efficient planning and installation.

Typically used in applications requiring robust and long-lasting conductive properties, the electrical grade aluminum busbars come in multiple shapes and configurations, including flat bar formats. The table below showcases sizes in mm, allowing for easy comparison against traditional copper bus options. Each aluminum busbar in the catalog is designed to deliver optimal performance, reliability, and cost-efficiency.

Electing to use an aluminum busbar enhances your system’s performance while minimizing the drawbacks often associated with heavier materials like copper. The detailed aluminum alloy specifications ensure compatibility with various electrical components, making it easier than ever to achieve your installation goals. The inclusion of flat and extruded aluminum busbar options in the table equips you with the versatility needed for diverse applications.

Regardless of whether you’re working with a flat or custom-shaped aluminum busbar, the reference table provides all the crucial details to make informed decisions. The key to maximizing efficiency lies in selecting the right combination of grade, size, and alloy type. With a detailed and easy-to-understand size reference table, optimizing your infrastructure with the right aluminum busbar becomes a straightforward and seamless process, ensuring reliable and long-lasting electrical performance.

In conclusion, understanding the nuances of aluminum busbar grades and specifications is crucial for optimizing electrical systems. AP Precision Metals is prided on offering high-quality electrical grade aluminum busbars that meet rigorous industry standards. Commitment to excellence ensures that the aluminum busbars deliver superior performance, reliability, and efficiency in your electrical applications. For more detailed information on the aluminum busbars and specifications, please contact AP Precision Metals today.

FAQs

Q: What distinguishes AP Precision Metals’ aluminum busbars?

A: AP Precision Metals’ aluminum busbars are crafted from top-grade aluminum alloys, ensuring excellent electrical conductivity and robust performance. Each busbar undergoes rigorous testing to meet stringent industry standards, guaranteeing reliable and efficient performance across various electrical applications.

Q: What are the benefits of using aluminum busbars over copper busbars?

A: Aluminum busbars provide several advantages over copper busbars, including a significant reduction in weight, making them easier to handle and install. They offer high electrical conductivity and serve as a cost-effective alternative without compromising performance. Aluminum’s lightweight nature facilitates easier installation and maintenance.

Q: What types of applications are electrical grade aluminum busbars suited for?

A: Electrical grade aluminum busbars are suited for a range of applications, including power distribution, electrical switchgear, and battery connectors. They are designed to handle high ampacity and maintain performance under demanding conditions, making them ideal for residential and industrial electrical systems.

Q: How do aluminum busbar sizes and specifications contribute to system optimization?

A: AP Precision Metals provides a comprehensive Conductive Aluminum Busbar Size Reference Table that details various aluminum busbar sizes and specifications. This helps customers select the right aluminum grade and dimensions suited to their project requirements, facilitating efficient planning, installation, and system optimization.

Q: Can I get custom aluminum busbar specifications from AP Precision Metals?

A: Yes, AP Precision Metals offers flexibility in aluminum busbar specifications to meet unique customer demands. The precision-engineered solutions cater to various requirements, ensuring optimal performance and durability. You can choose from a variety of alloys and shapes tailored to your specific electrical needs.

Q: What industry standards do AP Precision Metals’ aluminum busbars comply with?

A: The aluminum busbars adhere to ASTM standards and undergo rigorous testing to ensure integrity and reliability. They meet all essential industry standards for safe and efficient electrical conduction, providing assurance of superior quality and performance in demanding electrical applications.