Understanding Aluminum Busbar Applications: Types, Aluminum Bus Bars, Aluminum Bus Bar, Bus Bars, Bus Bar

AP Precision Metals excels in providing high-quality aluminum busbars designed to meet diverse industrial applications. Understanding the various types of aluminum bus bars, including aluminum bus bars and bus bars, is crucial for optimizing performance in electrical systems. Explore the comprehensive guide to learn about the different types, benefits, and applications of aluminum bus bars, ensuring your projects meet the highest standards of efficiency and reliability.

Understanding Aluminum Busbars: Key Advantages and Applications

AP Precision Metals understands the importance of selecting the right materials for electrical systems. Aluminum bus bars offer significant advantages. One major benefit is their capacity to exhibit high corrosion resistance, making them ideal for harsh environments. Moreover, aluminum busbar and aluminum flat bar systems are cost-effective solutions, offering significant savings compared to copper.

Our aluminum bus bars are also lightweight, facilitating easier installation and handling while still maintaining reliability and performance. Understanding aluminum allows engineers and designers to fully leverage these efficiencies. For example, aluminum flat bar designs are often used in simple grounding systems due to their excellent conductivity and durability.

In terms of applications, aluminum busbars are omnipresent in various industries. From power distribution to automotive systems, aluminum finds applications in areas that require high current flow and efficient heat dissipation. Additionally, aluminum bus bars are highly adaptable, easily machined, and shaped to meet specific requirements, making them suitable for many innovative projects.

When compared to copper, aluminum provides an effective alternative with unique benefits. Aluminum bus bars are more affordable and weigh significantly less, reducing the load and stress on structural components. Further, their ability to resist oxidation and corrosion ensures a longer lifespan even in demanding environments.

Overall, aluminum bus bars provide numerous advantages that make them suitable for various applications. By investing in aluminum bus bar systems, you ensure efficiency, cost savings, and durability. AP Precision Metals remains committed to providing the highest-quality aluminum products tailored to meet the specific needs of clients.

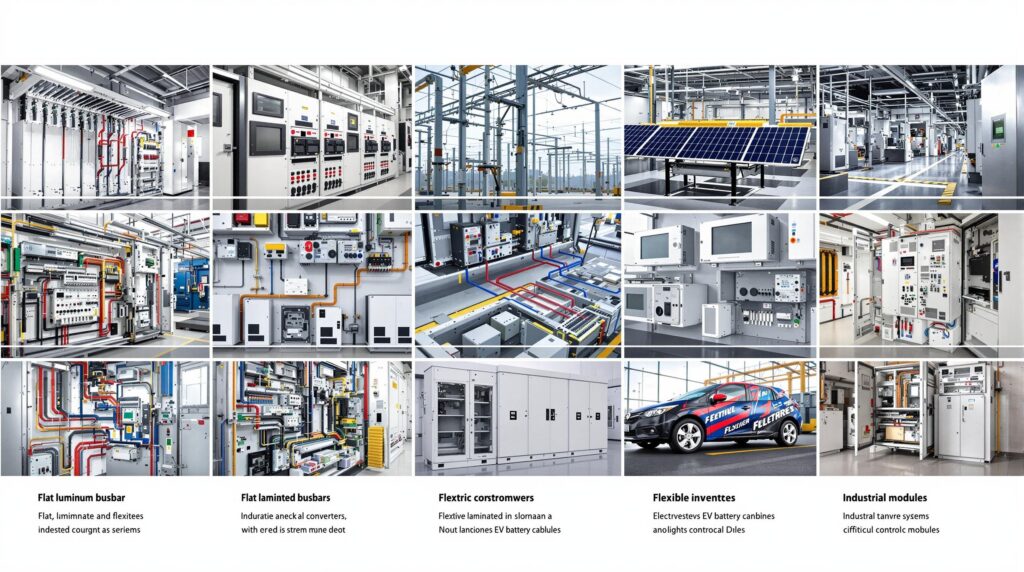

Types of Aluminum Bus Bars and Their Applications

Understanding aluminum bus bars and their various applications is crucial for efficient power distribution systems. Aluminum bus bars come in several types, each tailored to meet specific needs and applications. The most common types include the aluminum flat bar, often used in bus bar systems due to its excellent conductivity and flexibility. Another popular type is the extruded aluminum bus bar, known for its durability and capacity to handle high currents. Understanding aluminum busbar properties and the types of bar systems that leverage these benefits is essential.

Also, laminated aluminum bus bars enhance performance by reducing electrical resistance and distributing heat evenly, making them ideal for high-power applications. AP Precision Metals also have insulated aluminum busbars, which offer added safety by minimizing the risk of accidental short circuits. Each type of aluminum busbar is designed for specific applications, ensuring that power distribution is safe and efficient.

Furthermore, aluminum bus bars are not just limited to industrial applications. They’re also used in residential settings, where reliability and safety are paramount. Bus bars allow for streamlined electrical design, reducing the need for extensive wiring. Also, thanks to aluminum’s lightweight nature, these bus bars are easier to handle and install, reducing labor costs and time. By incorporating the right type of aluminum bus bar for your application, you can enhance your electrical system’s efficiency, safety, and longevity. Understanding the different types of aluminum bus bars and their applications is essential for selecting the right solution for your power distribution needs.

Essential Plating Techniques for Aluminum Bus Bars

When it comes to manufacturing aluminum bus bars, the use of essential plating techniques cannot be overstated. These techniques significantly improve conductivity and ensure that the aluminum busbars exhibit high corrosion resistance. Proper plating is crucial for maintaining the integrity of aluminum bus bar applications in various industries. Especially in simple grounding systems, an effective plating process on aluminum busbars can enhance performance and longevity.

Aluminum busbars are often used in electrical equipment and products due to their excellent electrical conductivity. One popular method is electroplating, where an electric current is utilized to deposit a layer of conductive material onto the aluminum bus bar. Another common technique is hot-dip galvanizing, where the aluminum busbars are submerged in molten zinc to create a protective layer.

Sheet plating methods are also employed to coat the surface of the aluminum bus, ensuring that each segment is resistant to environmental factors such as moisture and chemical exposure. These processes are vital for products that require high durability and efficiency. These plating techniques allow aluminum bus bars to operate efficiently in various applications, from simple grounding systems to complex electrical grids.

Furthermore, considering the harsh environments in which bus bars are often deployed, the finished aluminum bus must withstand different stressors without compromising performance. High-quality plating ensures that aluminum busbars remain reliable components in critical applications, thus enhancing the lasting value and dependability of the products and equipment they support. Thus, investing in essential plating techniques for aluminum bus bars is a best practice that ensures optimal functionality and reliability.

Key Components of Aluminum Busbars for Efficient Power Distribution

AP Precision Metals understands the essential role aluminum busbars play in efficient power distribution. Owing to their high conductivity and reliability, aluminum busbars are a key component in electrical equipment. They offer excellent electrical performance and contribute to the overall safety and efficiency of circuits. Using aluminum flat bars in busbar manufacturing enhances their versatility and adaptability to various applications. Furthermore, these aluminum busbars are available in numerous configurations, including flat bars and sheets, making them suitable for different kinds of equipment.

Aluminum bus bars’ lightweight and high-strength properties make them ideal for substantial current-carrying capacity while maintaining structural integrity. This is particularly important for applications requiring robust yet flexible metal solutions. By selecting the right aluminum bus bar, you can enhance the efficiency of power distribution systems without compromising on durability. When designed optimally, these bus bars minimize resistance and heat generation, thereby increasing the overall conductivity and reliability of the power distribution network.

Moreover, aluminum flat bars and sheets are used for their performance and cost-effectiveness. Their ability to handle high loads while remaining lightweight translates directly to reduced installation and maintenance costs. Given these advantages, aluminum busbars are preferred when considering power distribution circuits’ long-term value and sustainability. AP Precision Metals is committed to delivering top-quality aluminum bus bars tailored to meet specific needs, fostering innovation and efficiency in all electrical applications.

Conclusion: Exploring the Future of Aluminum Bus Bar Applications

As we’ve explored the diverse range of applications for aluminum bus bars, it’s evident that their role in modern electrical systems is expanding rapidly. The versatility of aluminum busbars makes them an excellent choice for various applications, especially where weight and conductivity are critical factors. With advancements in technology and materials, aluminum busbar solutions are continuously evolving, introducing innovations that promise efficiency and reliability.

AP Precision Metals stays ahead of industry news and trends, ensuring that aluminum bus bars and related product offerings meet stringent quality standards and emerging market needs. Whether you’re considering copper or aluminum for your bus bar applications, aluminum busbars clearly hold significant advantages in terms of flexibility, weight, and cost. The ability to tailor aluminum busbar products for specific applications makes them indispensable in fields ranging from renewable energy to automotive manufacturing.

AP Precision Metals focuses on essential techniques, including plating and insulation, ensuring that every aluminum bus bar they produce maintains optimal performance and durability. As the industry demand for efficient power distribution grows, the importance of choosing the right aluminum busbar cannot be overstated. The future of aluminum bus bars is promising and integral to achieving sustainable, high-performance electrical networks.

AP Precision Metals remains committed to pioneering new applications and discovering innovative uses for aluminum busbars. Staying updated with industry news and continuously refining the product line ensures that AP Precision Metals continues to be a leader in aluminum bus bar manufacturing. The future is bright for aluminum busbars, and we’re excited to be at the forefront of this dynamic industry.

Understanding aluminum busbars’ diverse applications and types is essential for optimizing electrical systems. AP Precision Metals is committed to providing high-quality aluminum bus bars tailored to your requirements. With expertise and innovative technologies, you can trust AP Precision to deliver efficient, reliable, cost-effective bus bar solutions. Contact AP Precision Metals today to learn more about the comprehensive range of aluminum busbars and how they can enhance your electrical infrastructure.

FAQs

Q: What are the primary advantages of using aluminum bus bars over copper bus bars?

A: Aluminum bus bars offer several advantages over copper, including cost-effectiveness, lightweight properties, high conductivity, and corrosion resistance. These attributes make aluminum bus bars ideal for various applications, from power distribution to automotive systems, ensuring efficiency and durability.

Q: What are the different types of aluminum bus bars available?

A: AP Precision Metals provides several types of aluminum bus bars, including aluminum flat bars, extruded aluminum bus bars, laminated aluminum bus bars, and insulated aluminum bus bars. Each type is designed for specific applications, enhancing performance and suitability for different industrial needs.

Q: How does aluminum bus bar corrosion resistance benefit electrical systems?

A: Aluminum bus bars exhibit high corrosion resistance, making them ideal for harsh environments. This resistance enhances the lifespan and reliability of electrical systems by preventing degradation due to environmental factors such as moisture or chemical exposure.

Q: How do plating techniques improve the performance of aluminum bus bars?

A: Plating techniques such as electroplating and hot-dip galvanizing significantly improve the conductivity and corrosion resistance of aluminum bus bars. Proper plating ensures that aluminum bus bars remain durable and efficient in various applications, from simple grounding systems to complex electrical grids.

Q: In which industries are aluminum bus bars most commonly used?

A: Aluminum bus bars are widely used in multiple industries, including power distribution, automotive, renewable energy, and residential applications. Their excellent conductivity, lightweight properties, and adaptability make them suitable for high current flow and efficient heat dissipation across diverse fields.

Q: Can aluminum bus bars be customized for specific project requirements?

A: Yes, aluminum bus bars can be easily machined and shaped to meet specific project requirements. This adaptability makes them suitable for a wide range of innovative projects, ensuring optimal performance and efficiency in tailored applications.

Q: How does the use of aluminum bus bars impact installation and maintenance costs?

A: The lightweight nature of aluminum bus bars facilitates easier installation and handling, reducing labor costs and time. Additionally, their corrosion resistance and durability result in lower maintenance costs over time, making them a cost-effective solution for electrical infrastructure.

Q: What role do aluminum flat bars play in bus bar systems?

A: Aluminum flat bars are often used in bus bar systems due to their excellent conductivity and flexibility. They are commonly employed in grounding systems and other applications where reliability and efficient power distribution are critical.

Q: How does AP Precision Metals ensure the quality of its aluminum bus bar products?

A: AP Precision Metals employs advanced manufacturing techniques, including essential plating and insulation processes, to maintain the highest quality standards. AP Precision Metals commitment to innovation and adherence to stringent quality controls ensures that their aluminum bus bars deliver optimal performance and reliability.

Q: Why is it important to stay updated with industry trends and advancements in aluminum bus bar technology?

A: Staying updated with industry trends and advancements ensures that AP Precision Metals can continuously refine and improve product offerings. This commitment to innovation allows them to meet emerging market needs and maintain a leadership position in aluminum bus bar manufacturing, ensuring the clients receive the most efficient and reliable solutions available.