Aluminum Busbars for Wind Power Installations: A Practical Guide to Aluminium Busbars, Bus Bars, and Wind Turbines

Welcome to AP Precision Metals’ comprehensive guide on Aluminum Busbars for Wind Power Installations. This detailed resource delves into the essential role of aluminum busbars, commonly referred to as bus bars, in optimizing the efficiency and reliability of wind turbines. Whether you’re an industry professional or a renewable energy enthusiast, this guide offers practical insights and technical information to help you harness the full potential of wind power using advanced aluminum busbar technology. Explore the synergy between cutting-edge material science and sustainable energy solutions.

Understanding Aluminum Bus Bars in Electrical Installations

In electrical installations, aluminum bus bars serve as central conductors, efficiently managing the distribution of electricity across various power systems. These bus bars, commonly called aluminum bus bars in regions outside of the United States, are crucial components that help maintain effective power transfer, particularly in wind power installations. The modern push toward renewable energy has emphasized the need for reliable and efficient electrical systems, making the role of aluminum bus bars ever more significant in wind turbines and other power sources.

The primary function of an aluminum busbar is to ensure the seamless flow of current within an electrical network, offering a strong and durable alternative to other materials like copper. Aluminum’s favorable attributes—such as its lightweight, high conductivity, and corrosion resistance—make it an excellent choice for bus bars in demanding environments. Another important aspect of installing bus bars is their ability to handle high current loads, significantly improving wind power systems’ overall reliability and efficiency.

Moreover, aluminum bus bars offer some advantages over copper, such as cost-effectiveness, while still delivering comparable performance for many applications. Installing these conductors involves meticulous planning and execution, ensuring the bus bars are precisely aligned and securely connected. Proper installation is key to optimizing their performance and longevity in a wind power installation. By adopting the use of aluminum bus bars, wind power installations can achieve better energy efficiency, reduce maintenance costs, and enhance lifespan. This guide will delve deeper into the essential guidelines for aluminum busbars, helping you understand their central role in efficient power distribution and offering practical insights into installing these critical components in your energy systems.

Essential Guidelines for Aluminium Busbars in Wind Power Systems

AP Precision Metals understands the crucial role aluminum bus bars play in optimizing wind power systems. Properly installed aluminum busbars ensure efficient power distribution and enhance the safety and reliability of the overall electrical system. Good practice dictates that all electrical installations, especially those in wind power applications, follow stringent guidelines to ensure performance and safety.

Our guidelines emphasize selecting the right type and quality of aluminum bus bar for your specific wind power system. When choosing your bus bars, consider factors such as the electrical load, environmental conditions, and compatibility with other components. Always adhere to manufacturer recommendations and industry standards during installation to achieve optimal performance.

Ensuring your aluminum busbars are correctly installed and well-maintained minimizes energy losses and potential hazards. Regular inspections and timely maintenance are good practices that ensure long-term reliability and efficiency. Moreover, adopting safety protocols during the installation process is paramount to avoid electrical mishaps and ensure the well-being of personnel. When integrating aluminum bus bars in your wind power systems, always follow these guidelines to guarantee peak performance and durability.

By implementing these good practice measures, AP Precision Metals helps you achieve a robust and efficient power generation system. Whether upgrading existing installations or embarking on new projects, the comprehensive guidelines for aluminum busbars will support your efforts in effectively harnessing wind power. Trust in AP Precision Metals to provide the expertise and quality products necessary for superior electrical installations in wind power applications.

The Central Role of Bus Bars in Efficient Power Distribution

Bus bars are central to efficient power distribution, particularly in energy generation systems such as wind turbines. Bus bars are critical components that facilitate the transfer of electrical energy from the source to various distribution points, ensuring seamless and reliable power flow. In wind power installations, aluminum bus bars are prevalent due to their lightweight and high conductivity characteristics, making them ideal for large-scale energy generation systems. Aluminum bus bars offer enhanced efficiency in power distribution, reducing losses and improving overall performance. Their corrosion resistance and thermal conductivity further contribute to their suitability for demanding environments like wind power installations.

Given the central role of bus bars in power distribution, it’s essential to choose the right material and design for optimal performance. By integrating aluminum busbars, electrical installations in wind turbines can achieve higher efficiency and durability. Additionally, these busbars support various system configurations, from simple power distribution layouts to more complex laminated busbar systems. This adaptability ensures that the energy generated by the wind turbines is effectively distributed to where it’s needed most.

Aluminum busbars also provide cost savings in material and maintenance, making them a preferred choice for many energy generation projects. The central role of bus bars extends beyond mere power distribution; they are essential for ensuring the stability and reliability of the entire electrical system. With the ever-growing demand for sustainable energy solutions, the significance of efficient power distribution systems, particularly those involving aluminum bus bars, cannot be overstated.

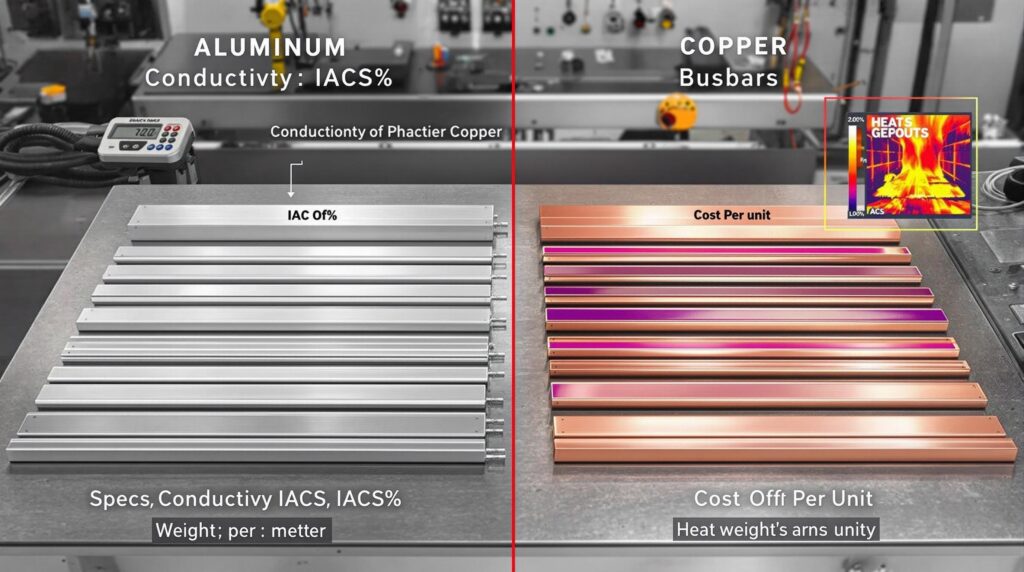

Aluminum vs Copper: Choosing the Right Bus Material

When selecting the right bus bar material for wind power installations, the choice between aluminum and copper can significantly impact the efficiency and cost of your electrical systems. Aluminum bus bars are increasingly popular in the wind energy sector because they’re lightweight yet robust, making them ideal for large-scale wind turbines. These aluminum conductors offer excellent electrical conductivity while being relatively more cost-effective than their copper counterparts. However, copper bus bars shouldn’t be overlooked, as copper is renowned for its superior electrical properties and higher conductivity per unit volume.

One of the primary benefits of using aluminum in wind power systems is its lower density, which means less weight and easier handling during installation. This can translate to reduced labor costs and faster project completion times. On the other hand, copper’s high durability and thermal conductivity make it a preferred option for environments requiring higher resistance to wear and tear. Ultimately, your decision will hinge on various factors such as budget constraints, electrical demands, and long-term maintenance considerations.

Both aluminum and copper bus bars excel in specific applications, and understanding these nuances can make a substantial difference in optimizing your wind energy installations. High-quality electrical products are crucial to ensure reliable and efficient energy distribution in wind power systems. AP Precision Metals offers customized solutions in aluminum and copper materials to meet the unique requirements of your wind power projects. By balancing the trade-offs between aluminum and copper, AP Precision Metals provides durable and efficient busbar options that can help you achieve your energy goals.

Practical Insights into Laminated Bus Bar Technology

AP Precision Metals offers profound insights into the pivotal role of laminated bus bar technology in modern power systems. Laminated bus bars are essential for ensuring efficient distribution of electricity in wind power installations, particularly in environments where aluminum and copper bus bars are utilized. The technology behind laminated bus bars enhances their functional reliability by minimizing current losses and improving overall efficiency in electrical setups. Utilizing laminated bus bar technology allows optimal current flow and helps significantly reduce electrical resistance, which is crucial for high-performance power systems.

By integrating advanced design techniques, laminated bus bars are capable of handling higher current densities while maintaining structural integrity, a vital attribute for wind power installations. Aluminum bus bars, compared to their copper counterparts, present a cost-effective and lightweight alternative without compromising performance. Selecting between aluminum and copper in laminated formats provides flexibility and efficiency tailored to varied electrical requirements. Practical applications of laminated bus bar technology minimize electromagnetic interference (EMI), ensuring smooth operations of complex electrical systems. This makes them an ideal choice for advancing the functionality of power systems within wind energy sectors.

Moreover, the insights offered into laminated bus bar technology reveal its contribution to improved heat dissipation, effectively managing thermal cycles and extending the lifespan of electrical components. AP Precision Metals is dedicated to delivering high-quality bus bar solutions that meet stringent standards of performance and reliability. Embracing laminated bus bar technology signifies a step forward in achieving energy-efficient, robust, and sustainable wind power installations.

How to Install Laminated Bus Bars in Wind Power Applications

When installing laminated bus bars in wind power applications, it’s imperative to follow a structured guide to ensure safety and efficiency. The installation process begins with a thorough assessment of the electrical requirements of your wind power systems. This involves determining the capacity and specifications of the aluminum bus bars needed for optimal performance. Before beginning the installation, verify that all components are extensively tested and comply with industry standards for electrical applications.

Once preparation is complete, position the laminated bus bars within the power systems carefully, ensuring they align correctly with the designated slots and interfaces. It’s crucial to ensure that the bus bars are placed accurately and securely fastened to handle the operational stresses. Utilizing proper tools and protective gear during the installation will ensure the electrical connections are safe and robust.

During the installation phase, follow best practices by cross-referencing each step with the guide provided by the bus bar manufacturer. This will help prevent potential electrical hazards and ensure the integrity of the power systems. Additionally, applying insulating materials where necessary ensures that the laminated bus bars provide stability and reduce the risk of short circuits or power faults.

After the bus bars are installed, conduct thorough testing to confirm that all connections are secure and functional. Proper testing and validation processes will highlight any issues that need addressing, ensuring that the wind power applications operate reliably and efficiently. By following these guidelines, you’ll guarantee a successful installation of laminated bus bars that enhance your wind power systems’ overall performance and safety.

Advantages of Using Aluminium Bus Bars in Wind Energy Installations

Adopting aluminum bus bars in wind energy installations offers numerous advantages, making them an ideal choice for modern power systems. Aluminum bus bars, known for their superior electrical and thermal conductivity, are crucial in managing the efficient transmission of power within wind energy installations. AP Precision Metals products, including various types of aluminum busbars, ensure optimal performance in electrical power systems. Aluminum bus bars are lighter than their copper counterparts, significantly reducing the overall weight of the installations, thereby improving structural efficiency and reducing transportation and handling costs.

Moreover, aluminum busbars exhibit excellent thermal properties, maintaining system stability by effectively conducting heat away from electrical components. This prevents overheating and extends the longevity of the power systems. The cost-effectiveness of aluminum as a raw material also makes aluminum busbars a more economical option for large-scale wind energy projects.

One of the practical benefits of using aluminum bus bars in wind energy installations is their corrosion resistance, which is particularly important given the harsh environmental conditions at wind turbine sites. This characteristic ensures long-term reliability and minimizes maintenance needs. Additionally, aluminum’s flexibility allows for easier fabrication and customization to fit specific installation requirements, enhancing the versatility of power systems.

In conclusion, the integrative use of aluminum busbars in wind energy installations contributes significantly to the efficiency and sustainability of electrical power systems. By choosing aluminum bus bars, stakeholders in the wind energy sector can achieve a balance between performance, cost, and environmental impact, ultimately supporting the growth of renewable energy sources.

AP Precision Metals is committed to providing top-tier aluminum busbars for wind power installations. Expertise in designing and manufacturing high-quality busbars ensures optimal efficiency and durability for your wind turbines. Partner with AP Precision Metals to leverage the benefits of precision-engineered bus bars that meet the rigorous demands of modern renewable energy solutions. Contact AP Precision Metals today to learn more about the products and how they can support your wind power projects.

FAQs

Q: What role do aluminum busbars play in wind power installations?

A: Aluminum busbars are critical components in wind power installations, serving as primary conductors for efficient power distribution within the electrical system. They ensure seamless current flow and enhance the reliability and efficiency of wind turbines.

Q: Why are aluminum busbars preferred over other materials like copper in wind power systems?

A: Aluminum busbars are favored due to their lightweight nature, high electrical conductivity, and corrosion resistance. They offer similar performance to copper busbars but are more cost-effective, providing significant advantages in terms of installation and maintenance.

Q: What are the key benefits of using aluminum busbars in terms of performance and cost?

A: Aluminum busbars provide numerous benefits, including superior electrical and thermal conductivity, reduced weight for easier handling and installation, cost-effectiveness, and excellent corrosion resistance. These benefits collectively enhance the efficiency, durability, and lifespan of wind power systems.

Q: What guidelines should be followed to ensure the proper installation of aluminum busbars in wind power systems?

A: Proper installation involves meticulous planning, ensuring precise alignment and secure connection of the busbars. Adhering to manufacturer recommendations and industry standards is crucial. Regular inspections and timely maintenance also play a significant role in optimizing performance and longevity.

Q: How does AP Precision Metals support the wind power industry with its aluminum busbars?

A: AP Precision Metals designs and manufactures high-quality aluminum busbars tailored for wind power installations. These products ensure optimal efficiency, durability, and reliability, backed by the comprehensive guidelines and expertise. AP Precision Metals helps stakeholders in the wind energy sector achieve superior power distribution and sustainable energy solutions.