PRECISION METAL FABRICATION

AP PRECISION: RELIABLY SUPERIOR QUALITY,

LOW-COST COMMERCIAL FABRICATION

Strategic Planning with Creative Solutions

Investment in the Most Advancing Tooling

Competitively Priced US-Based Production

OUR FABRICATION PROCESS

Full-scale fabrication services to meet your production demands

We provide top-quality services that scale with you, utilizing some of the most advanced technology in the fabrication industry. Our LEAN fabrication approach tackles production by product line, to maximize speed and minimize cost. Our range of fully-automated, semi-automated, and manual machines provides us with the flexibility to design an ideal workflow according to your process and volumes. We don’t stop there. By committing to invest in advanced fabrication machinery according to your specific product needs, we’re able to guarantee that you will stay at the forefront of pricing and quality in relation to your competitors.

OUR FABRICATION EQUIPMENT

We offer the latest and most advanced machinery to deliver the highest-quality products

LASER CUTTING

Our largest investments are in laser-cutting machines. These highly-automated machines drive down the cost of parts and simultaneously guarantee superlative quality. Recent technological advances have enabled us to offer part processing services that often beat the pricing of overseas competitors. AP Precision operates a range of fiber lasers, each providing its own advantages based on your specific requirements. Additionally, our redundancy in cutting machinery allows us to guarantee up-time and easily handle demand spikes.

PUNCH PRESS

Punch presses are the time-tested stalwart of sheet metal fabrication. While their cutting speed is slower than fiber lasers, they can automate high-value processes such as tapping, countersinks, bridge lances, louvers, and other formed features. These functions make them ideally suited to provide the best price for certain jobs.

FORMING

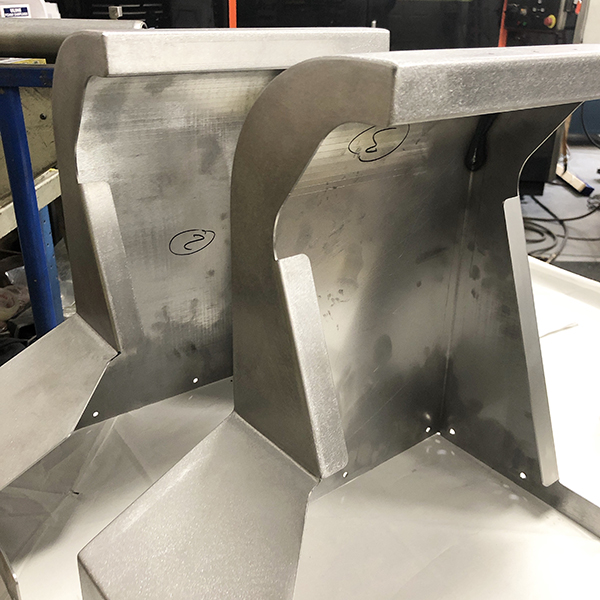

There are a wide array of forming machines available, but the most versatile are press brakes. For this reason, press brakes are the core of our bending operation. Our skilled operators run R&D and low-volume work. As your product reaches EAU volumes of 5,000+ we shift them to our automated press brake cells, so that you retain best-in-market pricing without having to switch suppliers.

WELDING

The welding department at AP Precision consists of multiple manual weld cells, robotic cells, and both hybrid manual and robotic formatting. This diversity is essential to achieving rapid new product ramp-ups and the lowest cost fabrication once products reach stable volumes. Welder certification, regular training and cross training enables our team to switch seamlessly from standard workflow to single-part workflow when a specific part or assembly is in high demand.

FINISHING

Finish coatings are essential to the customer experience. Passivation, masking, and finish coat are performed by our experienced team. For thick plate and automotive applications, we also provide Ultimate Linings’ Polyurea finish.

EXPLORE OUR FULL RANGE OF CAPABILITIES

We’re with you every step of the production process to increase efficiency and save money.

READY TO IMPROVE YOUR MANUFACTURING PROCESS?

Our team of experts will work to provide creative solutions best fit to your operations. Learn more about how AP Precision can meet your production needs and improve efficiency.