No matter the size of your company, your industry or project type, there’s a lot of advantages to hiring an experienced contract manufacturer.

The Benefits of AP Precision Contract Manufacturing

Many companies choose AP Precision for contract manufacturing because we handle rapid production increases as well as expedited prototypes, while also offering a flexible production mode (no matter the size of the client project!)

Contract manufacturing needs depend on the client, industry, and project type. Some different types of contract manufacturing include:

- Complex or complete assembly

- Machine control assembly

- Casting

- Metal forging, or metal shaping (for example, grinding or milling)

- Computer Numerical Control (CNC) Machining

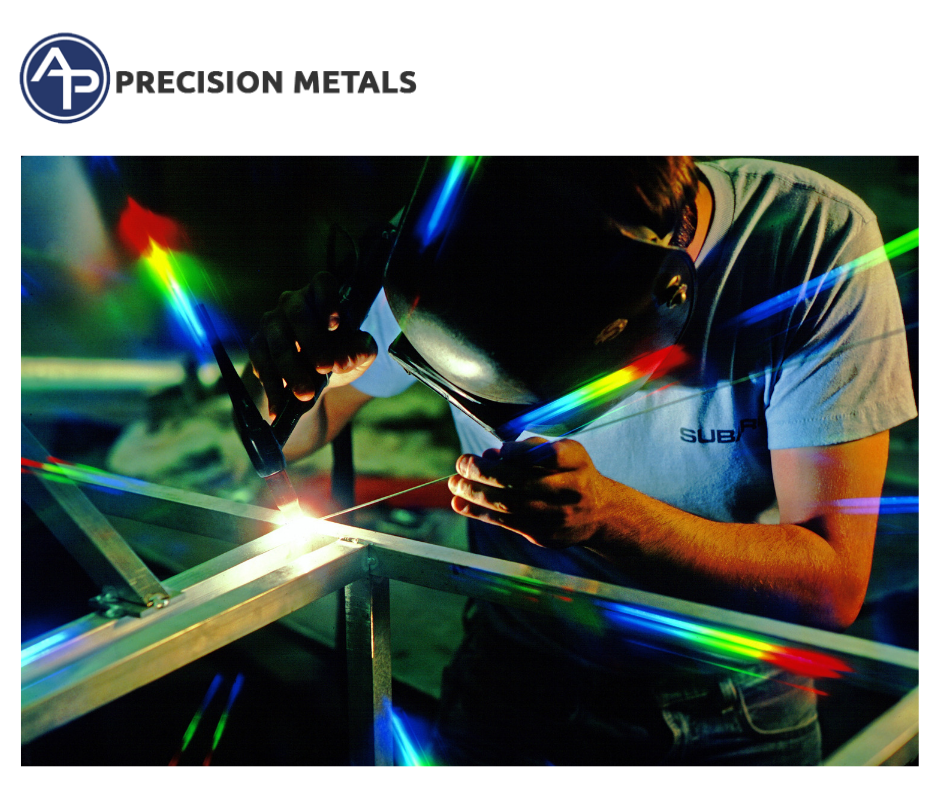

- More specifically, we offer precision metal fabrication, plate cutting, laser cutting, welding, powder coating as well as brass and copper cutting.

Some major benefits of contract manufacturing include:

- Better quality end-products. While we are able to handle many projects in-house, we continue to be a top choice for a variety of contract manufacturing jobs because we leverage our trusted partners to deliver a variety of other techniques such as anodizing, bright annealed plating, chem film, custom packaging, passivation, sand blasting, silk-screening and zinc plating. This means our turn-around time is faster while retaining the highest quality possible… and no matter the project, you’ll have access to a wide range of skill sets, from engineering to advanced manufacturing knowledge of tools like CNC machines, 3D printers, and precise cutting, drilling, or milling instruments.

- Cost reduction. Because you don’t have to purchase the instruments and tools yourselves (typically, safe and effective manufacturing requires a large staff of managers, engineers, operators, and skilled materials workers), you can keep overhead costs low, leading to a higher return on investment. This is ideal, especially for smaller businesses and startups who often don’t have the resources, budget, or staff to manufacture products on their own.

- Resource savings. By using techniques like lean manufacturing, there’s less waste which means better cost savings. Meanwhile, more of your internal budget can be allocated to other elements of your business such as marketing, sales and admin.

- Quicker turnaround. Rapid prototyping tools and CNC machining make the production process much faster than traditional manufacturing techniques, so products can hit the market faster.

- More end-to-end options. While some contract manufacturers will only handle certain parts of manufacturing, others, like AP Precision offer end-to-end services, meaning that they handle the entire process from start to finish. This includes product design, material purchases, the manufacturing, assembly, packaging, and shipping.

- Industry-specific products. Many industries, such as tech, robotics, bio-medical, or the military require niche design solutions. An experienced contract manufacturer can help create specialized instruments and may even be able to help refine the design over time.

- More accurate cost analysis. Contract manufacturers can provide a detailed cost estimate up-front so you know exactly how much the project will cost and how much you’ll need to set aside. This minimizes unexpected costs or delays and can help maintain a healthy budget.

About AP Precision

Founded in 1998, AP Precision was created to fill a need for metal products in order to meet the demands of their growing robotics company. Twenty-three years later, AP Precision has progressed to offer an array of contract manufacturing services in San Diego. Their founding principle is quite simple: to provide stable, long-term, precision metal fabrication for businesses of all sizes and shapes throughout Southern California.