As the year winds down, many businesses begin to shift their focus from active production to strategic planning—and in the welding and fabrication industry, December is an ideal time to lay the groundwork for a successful year ahead. Whether you’re in manufacturing, industrial services, or custom metalwork, using this quieter period to plan your welding and fabrication projects can save time, reduce costs, and ensure operational efficiency.

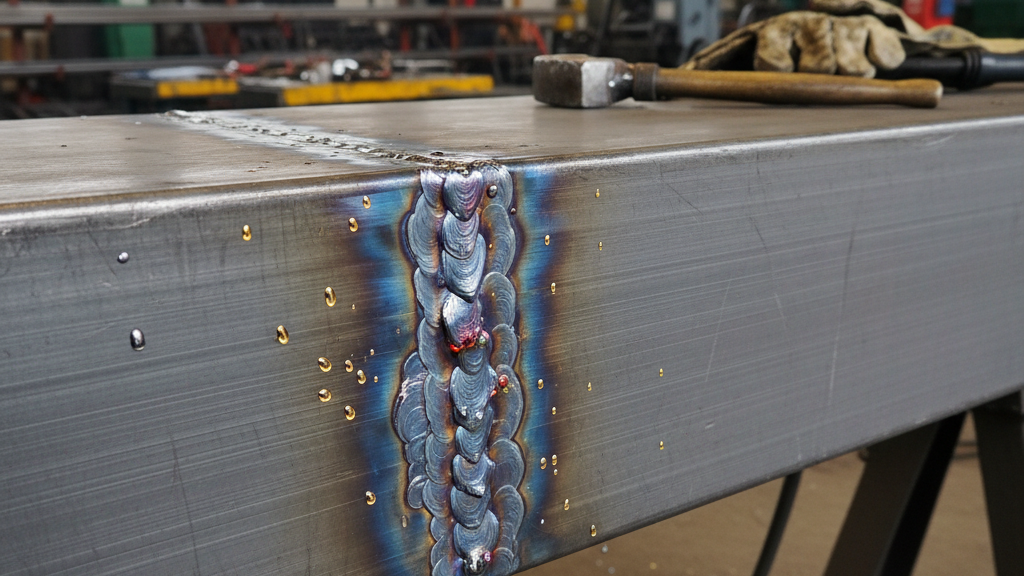

At AP Precision, we specialize in delivering high-quality welding and fabrication services tailored to meet the exact specifications of your project. December provides a valuable window to assess needs, secure timelines, and prepare for a strong start in the new year. Here’s why now is the time to plan ahead.

1. Year-End Budgeting Creates Opportunity

Many organizations finalize their annual budgets in Q4. If your company has remaining capital that needs to be allocated, investing in upcoming welding or fabrication projects is a strategic way to use those funds efficiently.

- Get ahead of price increases: Material and labor costs can rise in Q1. Planning and securing quotes in December can help lock in current rates.

- Optimize tax benefits: Equipment upgrades and capital improvements made before the end of the year may qualify for deductions or depreciation advantages.

2. Less Downtime, More Scheduling Flexibility

Many production environments slow down in December due to holidays and year-end inventory processes. This slower pace offers a natural opportunity to perform assessments, schedule off-peak work, or begin the design and quoting process without disrupting your operations.

- Collaborate with a fabrication partner during a period of lower activity.

- Use downtime for maintenance-related welding, prototype development, or project planning.

Working ahead in December means your fabrication needs are already in motion by the time Q1 ramps up.

3. Easier Coordination with Engineering and Operations

When production slows, engineering and operations teams typically have more bandwidth to focus on project planning and process improvement. This is an ideal time to work closely with your fabrication partner to:

- Review designs or blueprints

- Evaluate materials and structural requirements

- Identify cost-saving opportunities or process improvements

Early collaboration helps reduce design errors, avoid material shortages, and streamline the production schedule once execution begins.

4. Secure Priority Production Slots for the New Year

By planning your welding and fabrication projects in December, you can secure a place in your vendor’s production queue before lead times stretch in Q1. Demand often spikes in January and February, so getting ahead ensures your project is not delayed by a backlog of work.

At AP Precision, we prioritize early planning clients and can work with you to establish a timeline that aligns with your operational goals.

5. Plan for Process Improvements and Upgrades

December is an excellent time to review operational pain points from the past year and plan welding or fabrication solutions that improve efficiency. Whether it’s a redesign of existing components, reinforcement of critical parts, or a complete custom fabrication job, this is the right time to explore improvements without the pressure of immediate deadlines.

6. Align Projects with Your Q1 Launches

If you’re planning equipment upgrades, new product lines, or infrastructure improvements in Q1, having your fabrication needs planned out in December means those timelines stay intact. It’s far easier to launch a new system or process when the metalwork is completed, tested, and delivered on time.

Waiting until January to start planning can introduce unnecessary delays—especially when suppliers, materials, and fabrication schedules are all in high demand.

7. Strengthen Vendor Relationships

Planning projects well in advance is a sign of operational foresight—and it helps build stronger relationships with your fabrication vendor. When you engage early, you benefit from:

- Improved communication and lead time expectations

- Greater collaboration on design, materials, and efficiency

- Access to the best scheduling and service opportunities

At AP Precision, we value proactive clients who treat us like strategic partners. December is a perfect time to start that conversation.

Let’s Plan Ahead—Together

If your team is looking to hit the ground running in Q1, don’t wait until the calendar flips to January. Use December to evaluate, strategize, and coordinate your next welding or fabrication project with our expert team.

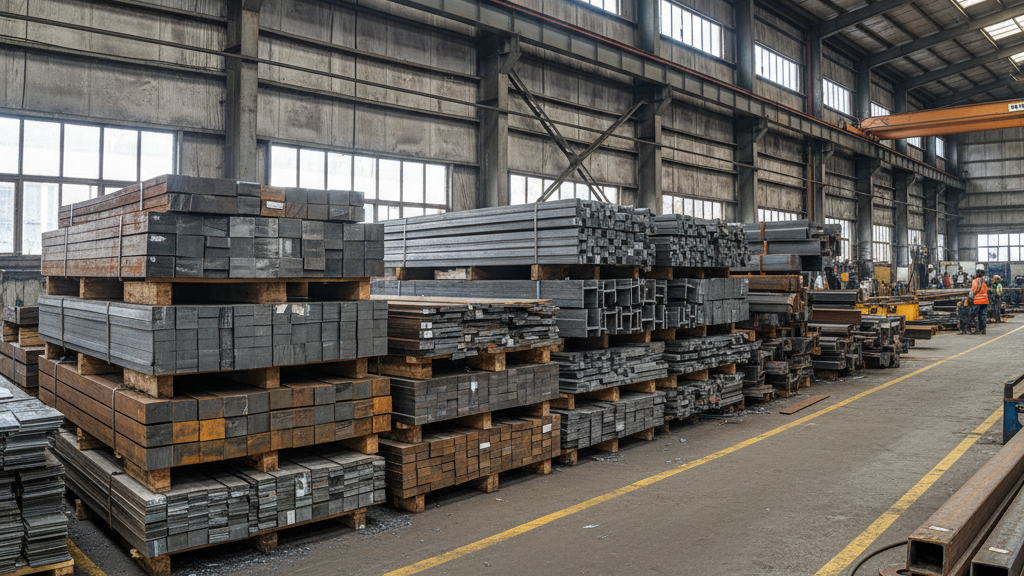

From small custom components to large-scale industrial fabrication, we bring precision, quality, and attention to detail to every job. Let’s work together to build a smarter plan for the new year—one that starts with action today.

Contact us now to discuss your project goals and secure your fabrication schedule for 2025.