As winter brings harsh weather, freezing temperatures, snow, and ice, infrastructure and components across many industries are put to the test. Poorly fabricated metal parts often fail when durability matters most. This results in costly emergency repairs, downtime, and wasted resources. At Apprecision, we believe that investing in high-quality sheet metal fabrication is a smart strategy to avoid those expensive winter repair bills. In this post, we explain how quality fabrication leads to long-term savings, what to look for in a fabricator, and how to design and select materials to minimize risk during the winter season.

The Risk of Cutting Corners in Winter Environments

When metal parts are exposed to winter conditions, weaknesses quickly become liabilities. Common issues include:

- Corrosion and rust caused by moisture, road salts, freeze-thaw cycles, and de-icing chemicals

- Fatigue and cracking from repeated thermal expansion and contraction

- Warping or distortion from temperature swings or improper tolerancing

- Loose joints or weak welds that fail under vibration or temperature stress

- Leaks or poor seals in enclosures that allow snow, water, or ice to enter

These failures often lead to unexpected repairs, emergency part replacements, and lost time. Emergency repairs in winter can be especially costly due to weather-related delays, overtime labor, and urgent shipping. Preventing these issues through quality fabrication can significantly reduce those expenses.

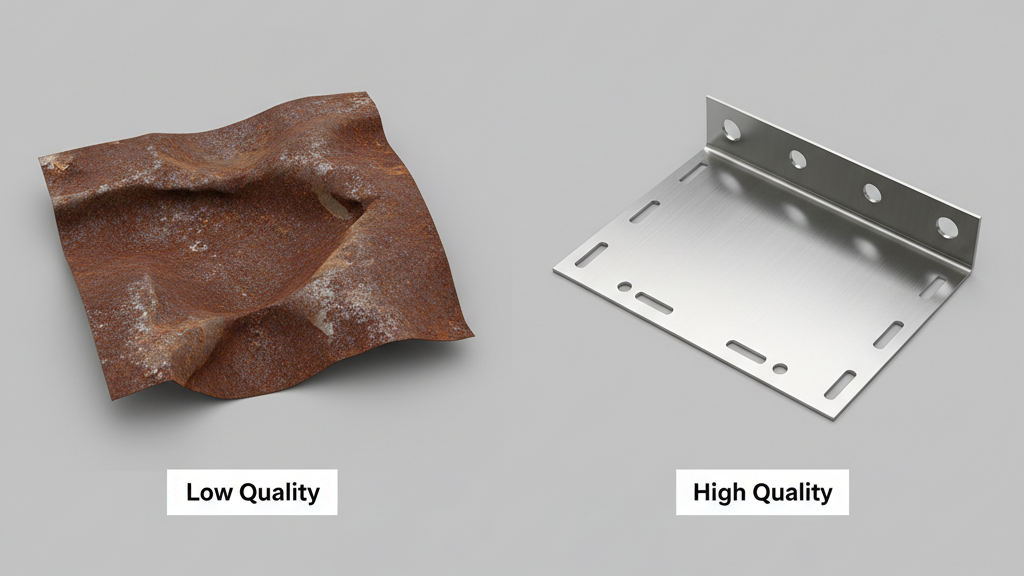

Why Quality in Sheet Metal Matters

Spending more on fabrication up front might seem like a higher cost, but it can save far more over time. Here are several ways quality pays off:

1. Fewer Defects and Less Rework

A high-quality fabricator holds tight tolerances, produces clean cuts, and performs precise welding. This results in fewer defects, less scrap material, and reduced labor costs due to rework or part rejection.

2. Better Materials and Finishes

Using corrosion-resistant materials such as stainless steel or applying proper coatings protects parts from winter weather. Galvanized finishes, powder coating, and proper surface treatments ensure durability against salt and moisture.

3. Proper Fit and Assembly

Precision fabrication ensures parts fit together without stress points or alignment problems. This reduces the chance of failure under cold weather strain or heavy loads. A well-fitted part lasts longer and requires less maintenance.

4. Durable and Repairable Designs

High-quality fabrication supports better engineering decisions. Modular designs, flanged edges, and removable panels make field repairs easier and less expensive. This approach limits damage and reduces the need to replace full systems.

5. Lower Total Cost Over Time

The initial cost of quality fabrication is often offset by fewer failures, less downtime, and lower repair bills in the long run. A well-made part might last multiple winters without issue, while a lower-cost alternative could fail within the first season.

Hidden Costs of Low Quality Fabrication

Choosing the lowest price option can lead to unexpected costs. Consider the following hidden factors:

- Extra time and labor for rework or replacement

- Shipping delays and higher freight costs during winter emergencies

- Loss of productivity or system shutdowns due to part failure

- Wasted material due to defects or improper cutting

- Damage to equipment or surrounding parts due to poor fit or corrosion

These costs often go unaccounted for when selecting a fabricator. However, they can quickly add up and make the lowest quote far more expensive over time.

Strategies to Prevent Winter Failures Through Better Fabrication

To avoid costly winter repairs, consider the following strategies when planning your sheet metal projects:

Collaborate Early with Your Fabricator

Working with your fabricator during the design phase allows for valuable input on materials, bend tolerances, and coating requirements. This avoids late-stage changes and reduces future maintenance.

Standardize Designs

Using consistent material thicknesses, bend radii, and part dimensions simplifies manufacturing and reduces mistakes. It also lowers production costs.

Optimize Sheet Usage

Efficient nesting and layout of parts minimizes scrap and reduces raw material cost. This improves yield and keeps prices down.

Reduce Unnecessary Complexity

Extra features such as small holes, tight radii, or overly complex bends can drive up costs and increase the chance of winter-related failure. Keep designs functional but simple.

Select Proper Materials and Coatings

Choose metals that resist corrosion and finishes that hold up in freezing, wet, or salty environments. Confirm that coatings are applied to specification and that parts are protected during fabrication and delivery.

Design for Easy Maintenance

Modular parts and accessible panels make field service quicker and cheaper. If one component fails, it can be replaced without taking apart the whole system.

How Apprecision Delivers Long-Term Value

At Apprecision, we specialize in high-quality sheet metal fabrication built to perform in all seasons. We help our clients save money over the life of their projects by focusing on:

- Accurate, reliable manufacturing with minimal defects

- Material and finish selection suited to your environmental needs

- Design guidance to simplify fabrication and reduce cost

- Inspection and quality control at every step

- Clear communication and on-time delivery

Our precision methods reduce the risk of failure and limit the need for repairs during the winter months. That saves our customers time, money, and stress when weather conditions are at their worst.

Cost Comparison Example

Consider the following comparison between a standard and high high-quality fabricated part:

| Feature | Standard Fabrication | Apprecision Quality |

|---|---|---|

| Initial Cost | 1000 | 1300 |

| Repair Cost Over 5 Years | 800 | 100 |

| Downtime and Labor | 2000 | 300 |

| Total Lifetime Cost | 3800 | 1700 |

As this example shows, quality fabrication can reduce total ownership costs by more than half, especially when winter wear and tear is factored in.

Plan Ahead to Save Money

Winter weather exposes the flaws in weak or poorly made parts. By planning ahead and choosing quality fabrication, you can avoid emergency repairs, prevent failures, and extend the life of your equipment. Thoughtful design and expert production can make a measurable difference in your bottom line.

If you are preparing for a project that will face winter exposure, contact us to discuss how we can help you fabricate smarter. Contact us today to get started with reliable, cost-saving sheet metal fabrication from Apprecision.