Aluminum busbars play a crucial role in modern electrical distribution systems. Known for their strength-to-weight ratio, conductivity, and cost-effectiveness, aluminum busbars are widely used across industries. However, like any integral electrical component, they require ongoing safety inspections to ensure reliable performance. Conducting fall safety inspections is especially important for identifying weak points that could compromise both safety and efficiency.

Why Aluminum Busbar Safety Inspections Matter

Busbars carry high electrical currents and serve as the backbone of electrical distribution in power plants, data centers, manufacturing facilities, and renewable energy systems. Because they are subject to constant mechanical and thermal stress, weak points can develop over time. Inspections are vital to detecting these issues early, preventing equipment failure, downtime, and potential hazards.

Fall inspections, performed before heavy seasonal loads and fluctuating weather conditions set in, provide an ideal opportunity to ensure that aluminum busbars remain in peak condition. With cooler temperatures and increased energy demands in many facilities, fall is the right time to evaluate their integrity and prevent costly breakdowns during high-use periods.

Common Weak Points in Aluminum Busbars

Over time, several factors can compromise the safety and reliability of aluminum busbars. Fall inspections should pay close attention to the following areas:

1. Mechanical Stress and Fatigue

Even though aluminum is lightweight and durable, busbars may experience mechanical stress due to vibrations, improper mounting, or repeated thermal expansion and contraction. These stresses can lead to cracks, bends, or even misalignment, all of which reduce overall performance.

2. Corrosion and Oxidation

While aluminum naturally forms a protective oxide layer, exposure to moisture or harsh environments can still lead to corrosion. Inspectors should check for discoloration, pitting, or surface degradation, which may weaken the conductivity and integrity of the busbar system.

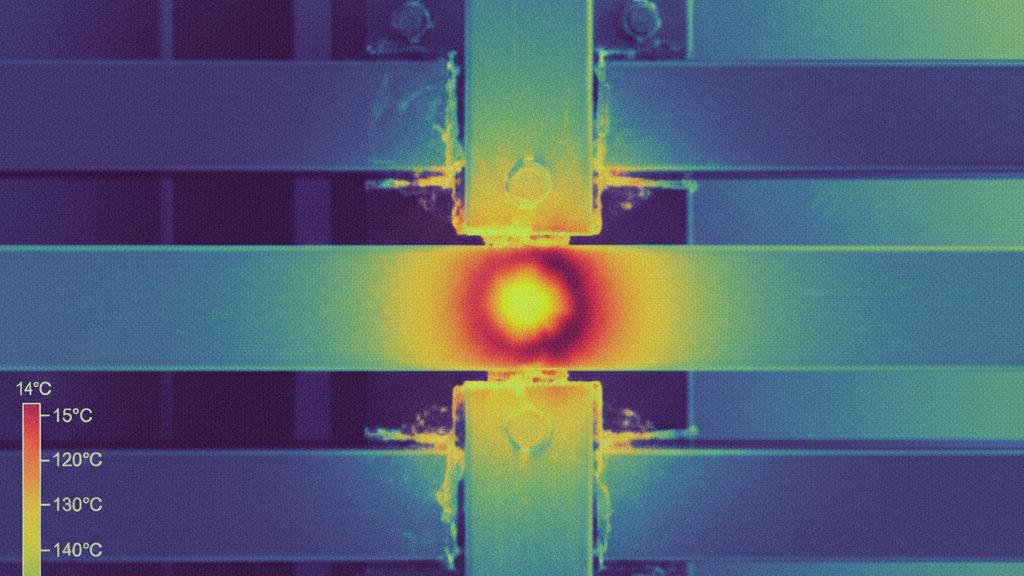

3. Overheating and Hot Spots

Uneven current distribution, loose connections, or undersized busbars can lead to hot spots. These areas are early indicators of electrical inefficiency and can pose fire risks if not addressed. Thermal imaging during fall inspections can help pinpoint these problem areas before they escalate.

4. Improper Coatings or Insulation Wear

Aluminum busbars are often coated or insulated to enhance performance and prevent oxidation. Over time, these coatings can degrade or wear away, leaving the underlying material vulnerable. Inspectors should evaluate the condition of protective layers to ensure continued reliability.

5. Connection Points and Joints

The joints where busbars connect to other electrical components are some of the most common weak points. Loose connections or improperly torqued fasteners can result in resistance buildup, overheating, and mechanical failure. Careful attention during fall inspections can prevent these costly issues.

Best Practices for Fall Busbar Inspections

To maximize safety and performance, inspections should be both thorough and methodical. Below are some best practices to follow during fall safety evaluations of aluminum busbars:

- Visual Inspection: Begin with a comprehensive visual review, checking for cracks, bends, discoloration, or signs of wear.

- Thermal Imaging: Use infrared cameras to detect hot spots and uneven current distribution.

- Torque Testing: Confirm that all connection points and joints are tightened to manufacturer specifications.

- Coating Assessment: Evaluate the condition of protective coatings and insulation, repairing or replacing as needed.

- Documentation: Keep detailed records of inspection findings to monitor recurring issues or patterns over time.

Benefits of Regular Aluminum Busbar Inspections

Proactive fall inspections not only improve safety but also deliver measurable benefits to facilities that depend on reliable power distribution. These benefits include:

- Reduced Risk of Failures: Early detection of weak points prevents costly downtime and emergency repairs.

- Extended Lifespan: Regular maintenance helps aluminum busbars perform at peak efficiency for longer periods.

- Enhanced Efficiency: Addressing hot spots and loose connections reduces energy loss and improves conductivity.

- Improved Safety: Inspections protect workers and equipment from electrical hazards associated with failing busbars.

Partnering with Experts in Aluminum Busbar Fabrication

Ensuring long-term safety and performance begins with high-quality aluminum busbar design and fabrication. Choosing a trusted manufacturer with precision expertise makes inspections and ongoing maintenance more effective. Quality materials, accurate engineering, and attention to detail during production reduce the likelihood of weak points appearing in the first place.

By combining expert manufacturing with regular fall inspections, facilities can confidently operate electrical systems that are safe, efficient, and reliable year-round.

Schedule Your Fall Safety Inspection

Identifying weak points in aluminum busbars during fall inspections is one of the best ways to prevent costly downtime and ensure long-term reliability. If you are ready to enhance the safety and performance of your busbar systems, contact us today to learn more.