As the seasons shift and cooler temperatures set in, the demands placed on electrical systems begin to change. While many associate thermal management challenges with summer heat, the reality is that colder operating conditions can also affect performance—especially for aluminum busbars. Preparing these critical components for seasonal transitions ensures consistent conductivity, optimal thermal performance, and reliable power distribution well into the colder months.

Understanding Thermal Performance in Aluminum Busbars

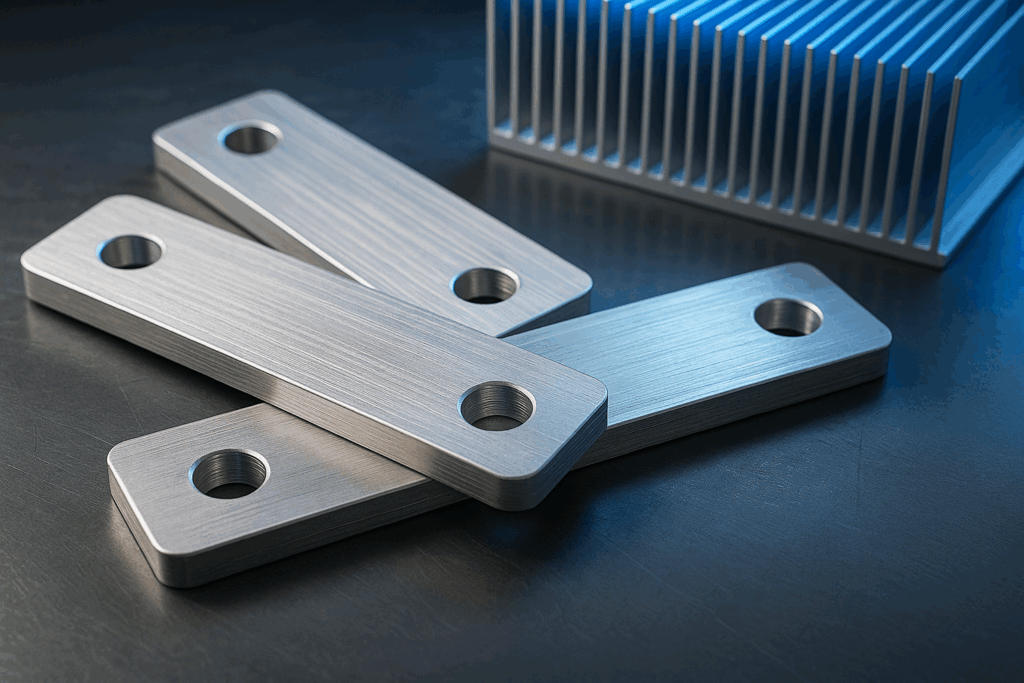

Thermal performance refers to the ability of a busbar to manage temperature changes without compromising electrical efficiency or mechanical integrity. Aluminum busbars are known for their excellent conductivity-to-weight ratio and strong resistance to corrosion, but temperature fluctuations—whether hot or cold—can influence their performance if not properly accounted for in design and maintenance.

In cooler weather, electrical load patterns often shift, and materials can respond differently to temperature variations. Ensuring that your aluminum busbars are optimized for these changes can prevent energy losses, connection issues, and long-term wear.

How Cooler Temperatures Affect Aluminum Conductivity

Aluminum’s electrical conductivity improves slightly as temperatures drop. This can be an advantage, as lower resistance means less energy lost as heat. However, cooler environments also bring unique considerations:

- Thermal contraction: Metals contract as temperatures decrease, potentially affecting mechanical connections if not properly designed or maintained.

- Condensation risks: Rapid temperature changes can lead to condensation on busbars, which may require additional protective measures.

- Load shifts: Seasonal changes in energy use can place different demands on busbar systems, requiring careful monitoring.

Key Steps to Prepare Aluminum Busbars for Cooler Operating Conditions

1. Inspect and Tighten Connections

Thermal cycling can loosen mechanical joints over time. Before the onset of colder weather, inspect all bolted or clamped connections and tighten them to manufacturer torque specifications to maintain optimal conductivity and reduce the risk of arcing.

2. Check for Surface Contamination

Dust, oxidation, and other contaminants can increase electrical resistance. A clean busbar surface ensures maximum conductivity and minimizes unwanted heating during operation.

3. Evaluate Insulation and Protective Coatings

In cooler conditions, moisture from condensation can become a greater concern. Ensure that insulation is intact and that protective coatings are in good condition to prevent corrosion.

4. Monitor Load Balancing

Changes in seasonal operations can lead to uneven load distribution. Use monitoring tools to ensure balanced current flow across all phases to avoid localized heating or reduced system efficiency.

5. Perform Thermal Imaging

Even in cool weather, hotspots can occur due to poor connections or load imbalances. Infrared thermography can identify these problem areas before they lead to failures.

Benefits of Cooler Weather on Aluminum Busbar Performance

While cold conditions bring certain challenges, they also offer performance advantages for aluminum busbars:

- Reduced overall operating temperatures improve system efficiency.

- Lower resistive losses can lead to minor energy savings.

- Extended lifespan for busbars due to less thermal stress compared to hot environments.

By proactively preparing for seasonal changes, facility managers can take advantage of these benefits while minimizing potential risks.

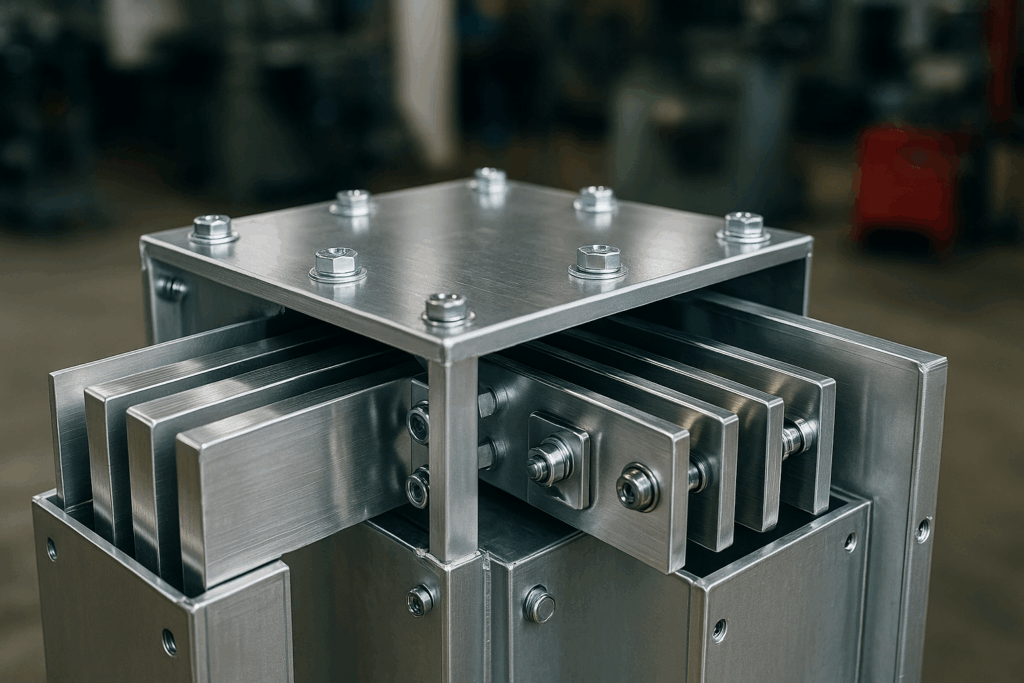

Why Precision Fabrication Matters for Thermal Performance

High-quality aluminum busbars designed and manufactured with precision are better equipped to handle seasonal temperature swings. At AP Precision Metals, we fabricate busbars to exact specifications, ensuring proper fit, superior conductivity, and exceptional durability in any environment.

From advanced CNC machining to careful finishing processes, our approach ensures that each busbar is built to withstand both hot summer loads and cold winter conditions without performance degradation.

Plan Now for Reliable Winter Operations

Preparing aluminum busbars for cooler operating conditions is not just a matter of routine maintenance—it’s a strategic step toward maximizing performance and minimizing downtime. By addressing thermal performance now, you can ensure your electrical systems operate at peak efficiency throughout the colder months.

Contact Us

Ready to optimize your aluminum busbars for the season ahead? Contact us to discuss inspection, preparation, or custom fabrication solutions tailored to your operational needs.