As the third quarter draws to a close, it’s the perfect time to evaluate the performance and condition of your electrical systems. For many industrial, commercial, and energy operations, aluminum busbars are the backbone of reliable power distribution. However, even the most durable busbars require periodic inspection to ensure they continue operating at peak efficiency. This September, a thorough busbar check can help you avoid costly downtime, improve system performance, and start Q4 with confidence.

Why September Is the Ideal Time for Busbar Inspections

The transition from summer to fall often brings shifts in operational demands. Whether it’s gearing up for seasonal production increases, preparing for higher heating loads, or finalizing projects before year-end, now is the time to ensure your electrical infrastructure is ready.

- Prevention before peak demand: Identifying issues early prevents costly failures during critical periods.

- Budget alignment: Q3 inspections allow time for repairs or replacements within the current fiscal year.

- Safety assurance: Regular checks help mitigate risks associated with worn or damaged busbars.

Signs Your Aluminum Busbars May Need Attention

While aluminum busbars are known for their long service life, they are still subject to wear, environmental exposure, and operational stresses. Keep an eye out for these warning signs:

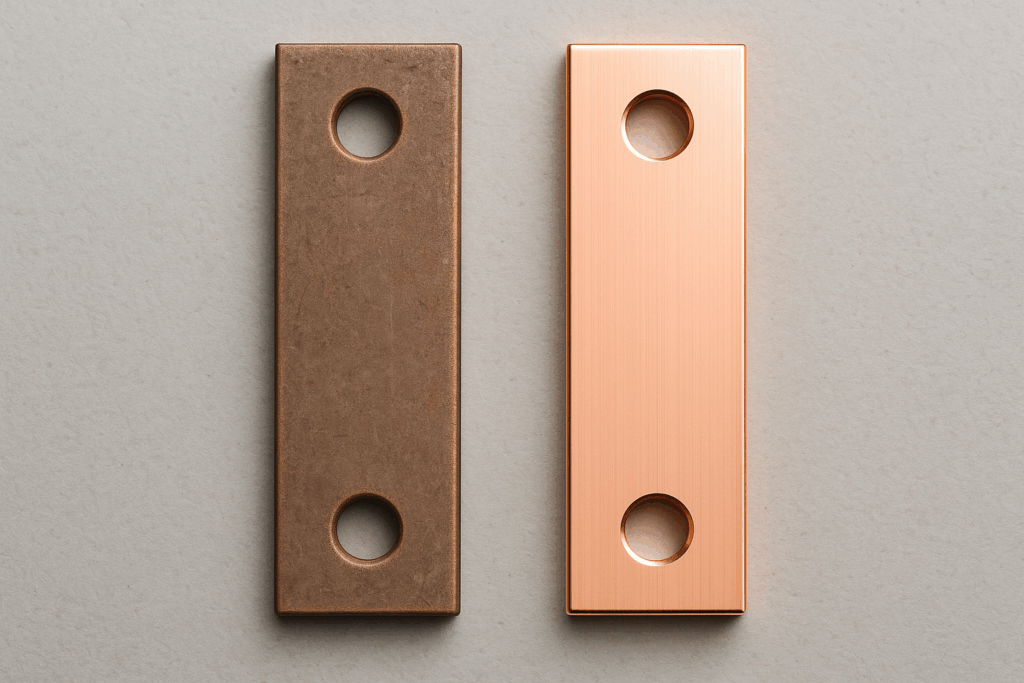

- Visible corrosion or pitting: Even with protective finishes, environmental factors can cause surface deterioration.

- Discoloration or burn marks: Indications of overheating or arcing at connection points.

- Loose connections: Can lead to increased resistance, heat buildup, and eventual failure.

- Unusual system behavior: Voltage drops, flickering lights, or irregular equipment performance.

Step-by-Step September Busbar Inspection Checklist

1. Power Down and Ensure Safety

Always follow proper lockout/tagout procedures before working on any electrical equipment. This ensures safety for all personnel involved.

2. Visual Examination

Inspect busbars for corrosion, discoloration, mechanical damage, or deformation. Pay close attention to areas around joints and connection points.

3. Connection Tightness

Check and tighten mechanical fasteners according to manufacturer torque specifications. Loose connections can lead to overheating and electrical faults.

4. Insulation Integrity

For insulated busbars, inspect the covering for cracks, abrasions, or other signs of wear. Damaged insulation can lead to short circuits or electrical leakage.

5. Thermal Scanning

Use infrared thermography to detect hot spots that are not visible during a standard visual inspection. Elevated temperatures may indicate excessive resistance or load imbalance.

6. Documentation

Record all findings, including photos, temperature readings, and any measurements. This documentation can help track trends over time and plan proactive maintenance.

When Replacement Is the Best Option

In some cases, repairing or adjusting worn aluminum busbars isn’t enough. If the damage is severe or the system is outdated, replacement can offer significant benefits:

- Improved conductivity and efficiency with new, precision-engineered busbars.

- Enhanced corrosion resistance from modern aluminum alloys and surface treatments.

- Optimized fit and performance through custom fabrication.

At AP Precision Metals, we specialize in manufacturing high-quality aluminum busbars tailored to your system’s exact requirements. Our advanced fabrication techniques ensure optimal performance, durability, and ease of installation.

Planning Ahead for Q4 and Beyond

Proactive maintenance in September sets the stage for a more productive and stress-free Q4. Addressing busbar issues now helps you:

- Avoid unexpected downtime during peak operating periods.

- Maintain compliance with safety and operational standards.

- Optimize energy efficiency for lower operating costs.

Partner with Precision for Lasting Results

Whether you need a full replacement or a targeted upgrade, working with an experienced metal fabrication partner ensures the job is done right. At AP Precision Metals, we combine expert engineering, advanced manufacturing capabilities, and rigorous quality control to deliver busbars that meet your performance, budget, and schedule requirements.

Contact Us

Don’t wait for electrical problems to disrupt your operations. Contact us today to schedule your aluminum busbar inspection or discuss replacement options before Q4 begins.