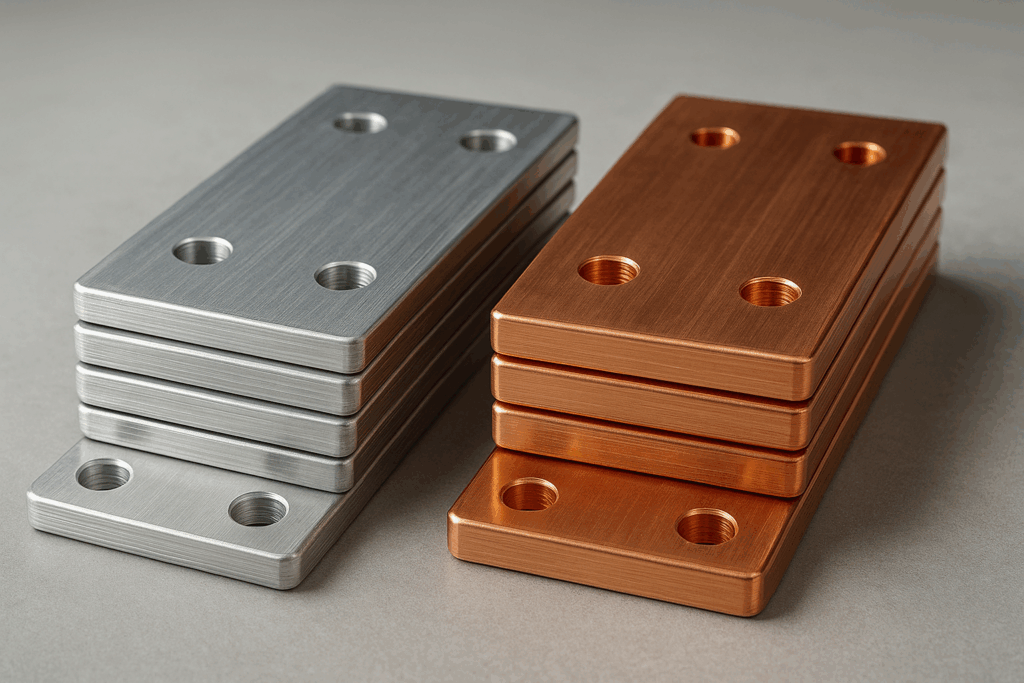

As industries continue to modernize electrical infrastructure, one component is quickly gaining attention across engineering, manufacturing, and energy sectors: the aluminum busbar. Once overshadowed by copper, aluminum is stepping into the spotlight this fall as a cost-effective, lightweight, and high-performance option for electrical distribution systems. For companies seeking efficient, precise, and durable solutions, aluminum busbars are proving to be a smart choice.

Understanding the Role of Busbars in Electrical Systems

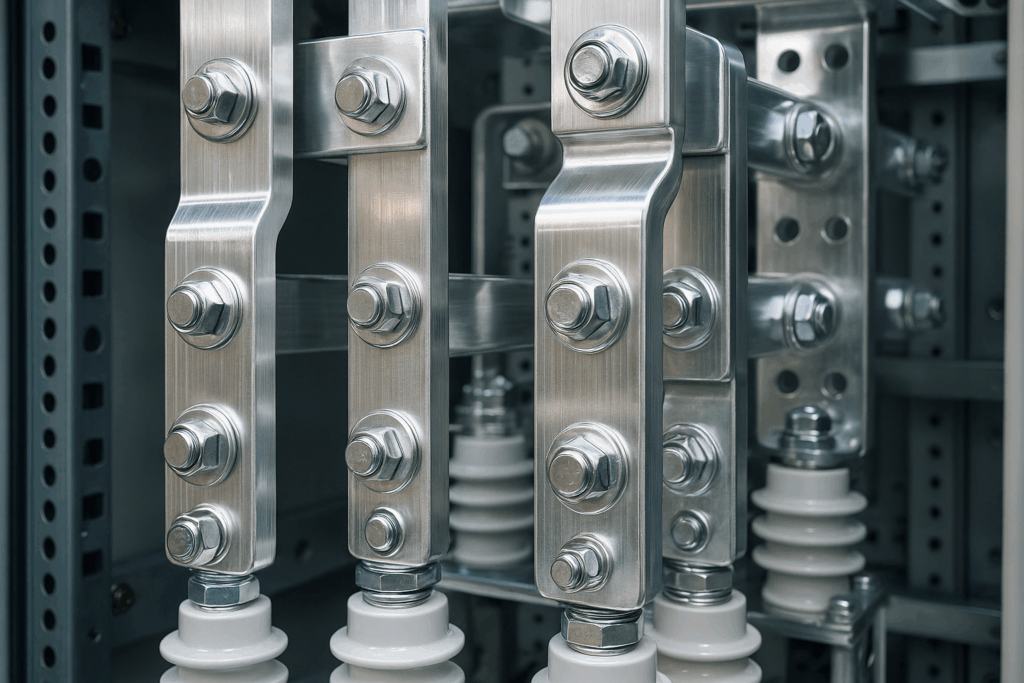

In electrical applications, busbars serve as the main conductors that distribute power within switchgear, panel boards, and other electrical apparatus. Their function is to carry substantial amounts of current while minimizing energy loss, heat buildup, and physical footprint. The choice of busbar material significantly impacts performance, cost, and longevity of the system.

Traditionally, copper has been the go-to material because of its high conductivity. However, as engineering priorities evolve and supply chain conditions shift, aluminum busbars are increasingly becoming a preferred alternative—especially for large-scale installations and high-current applications.

The Rise of Aluminum in Modern Electrical Design

Several factors are fueling the increased adoption of aluminum busbars this fall. From market trends to material advantages, the shift isn’t simply about replacing copper—it’s about optimizing performance and value for today’s operational needs.

1. Cost Efficiency Without Sacrificing Performance

One of aluminum’s most compelling advantages is its lower cost. Aluminum is significantly less expensive than copper, both in raw material pricing and in the total cost of implementation. This price stability is especially important in the current economic climate, where copper’s market volatility can impact project budgets.

2. Lightweight and Easy to Work With

Aluminum’s lower density makes it far lighter than copper—about one-third the weight for the same volume. This reduced weight means easier handling, simpler installation, and reduced structural load. For industries working with large-scale busbar systems, lighter components can translate into shorter installation times and lower labor costs.

3. High Conductivity for Practical Applications

While copper is more conductive per volume, aluminum delivers comparable performance when designed to appropriate specifications. Engineers often adjust the cross-sectional area of aluminum busbars to achieve equal or better electrical capacity without excessive material use. This ensures that aluminum busbars can handle heavy electrical loads efficiently.

4. Corrosion Resistance and Long-Term Reliability

Modern aluminum alloys and surface treatments offer impressive corrosion resistance. With proper fabrication, finishing, and installation techniques, aluminum busbars can operate reliably for decades—even in challenging industrial environments. This durability helps ensure consistent performance and reduces maintenance costs over time.

Why This Fall Marks a Turning Point

Seasonal shifts in energy demand, supply chain stability, and construction activity are making aluminum busbars especially relevant this fall. Electrical contractors and manufacturers are re-evaluating material choices to meet project deadlines, manage budgets, and adapt to increased demand for sustainable infrastructure.

- Supply chain resilience: Aluminum supply has been more stable compared to copper, minimizing delays.

- Sustainability focus: Aluminum is highly recyclable, supporting environmentally responsible project goals.

- Rising copper costs: Market fluctuations have made copper less predictable in cost planning.

Applications Where Aluminum Busbars Excel

Aluminum busbars are well-suited for a wide range of electrical systems, especially where size, cost, and efficiency are key considerations.

Industrial Power Distribution

Manufacturing facilities often require large-scale electrical systems that handle high current loads. Aluminum busbars offer the conductivity needed for heavy machinery and production lines without the excessive weight or cost of copper.

Renewable Energy Installations

Solar farms, wind power plants, and other renewable energy projects benefit from aluminum’s lightweight properties, which make transportation and installation simpler while still delivering robust electrical performance.

Data Centers

With growing energy demands, data centers need reliable, high-capacity power distribution systems. Aluminum busbars offer the efficiency and scalability these facilities require while helping manage material costs.

Precision Fabrication Matters

The performance of aluminum busbars isn’t determined by material alone—it depends heavily on precision engineering and manufacturing. At AP Precision Metals, expert craftsmanship ensures each busbar meets exact specifications for conductivity, durability, and fit.

From advanced CNC machining to meticulous surface finishing, every step of the production process is designed to maximize performance and longevity. This attention to detail helps clients integrate aluminum busbars seamlessly into their electrical systems, ensuring reliable operation from day one.

Making the Switch: Key Considerations

Before replacing copper with aluminum busbars, it’s important to evaluate factors such as:

- Electrical load requirements: Proper sizing ensures optimal performance.

- Joint connections: Specialized fittings and finishes prevent oxidation at contact points.

- Thermal expansion: Aluminum expands more than copper, so allowances should be made in design.

- Compliance with standards: Ensure materials and designs meet relevant electrical codes and industry guidelines.

By working with a skilled metal fabrication team, these considerations can be addressed early in the design process, ensuring a smooth and successful transition to aluminum busbars.

Looking Ahead

As the electrical industry continues to adapt to shifting economic, environmental, and technological priorities, aluminum busbars are set to play an even greater role. Their combination of affordability, strength, and adaptability makes them an attractive choice for projects in virtually every sector.

This fall’s momentum toward aluminum is not just a seasonal trend—it’s part of a broader movement toward smarter, more sustainable electrical infrastructure. Companies that invest in precision-fabricated aluminum busbars today are positioning themselves for long-term operational success.

Contact Us

Interested in learning how precision-engineered aluminum busbars can enhance your next electrical project? Contact us to discuss your requirements and explore the right solution for your application.